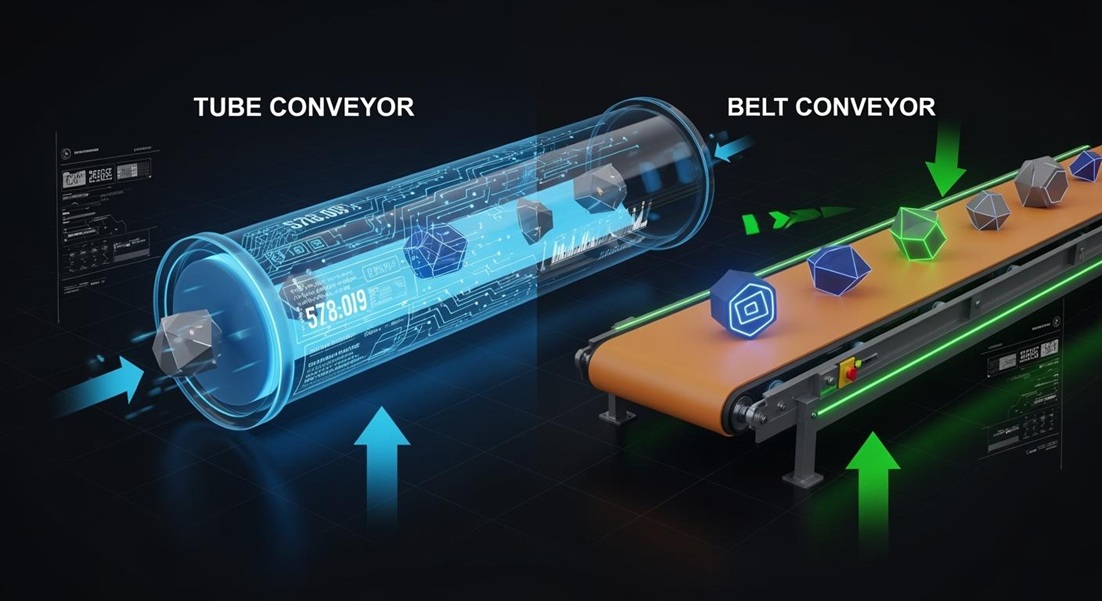

You might ask what makes a Tube Belt Conveyor different from a conventional conveyor. You may also wonder which one is better for you. The biggest difference is in the design and how they move materials. Tube Belt Conveyor keeps materials inside. This helps stop spills and dust. Conventional conveyor systems use an open belt to move things. Many industries use both types. These include automotive, food and beverage, chemicals, healthcare, industrial automation, and packaging.

|

Industry |

Type of Conveyor |

|---|---|

|

Automotive |

Tube and Conventional |

|

Food & Beverage |

Tube and Conventional |

|

Chemicals and Materials |

Tube and Conventional |

|

Healthcare |

Tube and Conventional |

|

Industrial Automation |

Tube and Conventional |

|

Packaging |

Tube and Conventional |

You should think about design, how it handles materials, space, maintenance, cost, and if it fits your needs to choose the best one.

Conveyor Types Overview

There are many kinds of conveyors. Each type does a special job. Some move food in a safe way. Others carry heavy things or help products go up and down. Here are some common conveyor types you might see in factories and warehouses:

|

Type of Conveyor |

Description |

|---|---|

|

Food Processing Conveyors |

Made to move food safely and quickly. |

|

General Material Handling |

Used to move things across short spaces in a building. |

|

Bulk Material Handling |

Good for lots of dry stuff, raw goods, and heavy items. |

|

Belt Conveyors |

Regular conveyors for many uses. |

|

Chain Conveyors |

Uses chains to move heavy loads. |

|

Spiral Conveyors |

Moves products up or down in a spiral. |

|

Modular Belt Conveyors |

Can be changed to fit different jobs. |

|

Incline/Decline Conveyors |

Moves things up or down at an angle. |

|

Bespoke Systems |

Custom systems like multi-lane, merge, and cooling conveyors. |

Tube Belt Conveyor Basics

A tube belt conveyor keeps materials safe and inside. The belt wraps into a tube shape as it moves. This design helps stop spills and keeps dust in. You see tube belt conveyors where you need to protect the environment or keep things clean. They can turn and change direction easily. Tube belt conveyors work well for moving lots of material. They help avoid mess and loss. Some people call them pipe conveyors because they look round.

Conventional Belt Conveyor Basics

A conventional conveyor has a flat, open belt. It moves items from one spot to another. Many industries use this type because it is simple and works well. The open belt makes loading and unloading easy. You can use it for boxes, bags, or loose things. It is best when you do not worry about dust or spills. You find these conveyors in packaging lines, warehouses, and assembly plants. The simple design lets you put it in many layouts.

Design Comparison

Tube Belt Conveyor Design

A tube belt conveyor has a special shape. The belt wraps into a closed tube as it moves. This keeps your materials safe inside. You do not have to worry about spills or dust. Many people call it a pipe conveyor because it looks round and closed. You can use it where you need to keep things clean or protect nature.

Tube belt conveyors can go around things or up steep slopes. This makes it easy to fit them in small or tricky spaces. The closed design also makes them last longer. The belt and what you carry stay safe from harm. You get better results and less time fixing problems.

Here is a quick look at the main features:

|

Feature |

Tubular Belt Conveyors |

Conventional Belt Conveyors |

|---|---|---|

|

Design |

Encloses materials in a tube-like shape |

Open belt configuration |

|

Spillage Prevention |

Yes, prevents spillage and contamination |

No, materials are exposed |

|

Routing Options |

Complex routing and steep incline capabilities |

Limited routing options |

|

Durability |

Higher due to enclosed design |

Varies, generally lower |

|

Efficiency |

Enhanced operational efficiency |

Standard efficiency |

Conventional Conveyor Design

A conventional conveyor has a flat, open belt. You see this kind in many factories and warehouses. The open belt makes loading and unloading simple. You can move boxes, bags, or loose stuff easily. This type works best if you do not need to stop dust or spills.

Conventional conveyors have a simple layout. They usually go in straight lines or gentle turns. It can be hard to fit them in tight spots or sharp corners. How long they last depends on where and how you use them. The open design can let the belt and items get worn out. Still, they work well for many normal jobs.

Tip: Pick a tube belt conveyor if you want to keep your materials safe or need more ways to set up the conveyor. Choose a conventional conveyor for simple layouts and easy loading.

Material Handling

Spillage & Dust Control

You want your workspace to stay clean. Tube belt conveyor systems help with this. The belt wraps into a tube shape. This keeps materials inside while moving. You do not see dust or spills. This design is good for places that need clean air. It helps protect the environment. Pipe conveyor models help you follow safety rules. These rules are important in food, chemical, and healthcare jobs.

Conventional conveyor systems use an open belt. You may see more dust and spills with these. Loose materials can fall off the sides. Dust can get into the air. You might need covers or extra cleaning to stop messes. If you move powders or fine bulk goods, you may have more problems with a conventional conveyor.

Note: Tube belt conveyor systems help you clean up faster and keep your facility safe.

Bulk Material Versatility

You need a conveyor that can move many kinds of bulk materials. Tube belt conveyor systems handle things gently and work well. You can move grains, powders, pellets, or sticky stuff. The closed tube design keeps everything inside. You do not lose product while moving it. These systems work for long distances or tricky routes.

Conventional belt conveyor systems are good for boxes, bags, and some bulk goods. They may not work as well with fine powders or sticky items. Spills and dust can make them less useful. You may need to change your setup for each material.

Here is a quick look at how each system works:

|

Advantages |

Disadvantages |

|---|---|

|

High Efficiency |

Prone to Spillage |

|

Gentle Handling |

Maintenance Requirements |

|

Flexible Design |

N/A |

Tube belt conveyor and pipe conveyor systems work better for bulk material handling. Conventional conveyor systems may need more cleaning and care.

Space & Layout Flexibility

Routing & Installation

When you set up a conveyor, you must think about space. Tube belt conveyors give you many ways to set them up. They can go straight, up, down, or around corners. This makes them good for tight or tricky spots. You can use a tube belt conveyor where other types may not fit.

Conventional belt conveyors also have some layout choices. You can put them in straight lines or gentle curves. They can go up or down slopes too. But if your building has lots of turns or changes in height, it can be harder to use a conventional conveyor. These do not work well with sharp corners or steep slopes like tube belt conveyors do.

Tip: If your workspace has lots of obstacles or needs a conveyor to twist and turn, a tube belt conveyor can make installation easier.

Inclination & Footprint

You want to use your floor space in the best way. Tube belt conveyors do not take up much room. Their design lets you put them in small spaces. You can install them under low ceilings because they are not tall. The parts can be changed easily if you need to move things later.

Here are some reasons why tube belt conveyors save space:

-

Small size helps you use floor space well

-

Modular design makes changes easy

-

Low height fits under short ceilings

Conventional belt conveyors can fit into many layouts too. You can use them for straight paths, curves, or slopes. But they may need more room for turns or going up and down. If your layout is simple, a conventional conveyor works fine. For small or hard-to-fit spaces, tube belt conveyors give you more choices.

Note: Always measure your space and check ceiling height before choosing a conveyor system.

Maintenance & Durability

Tube Belt Conveyor Maintenance

You want your conveyor to last a long time. Tube belt conveyors for long-distance material handling need regular checks to work well. Look for worn spots on the belt and rollers. The closed tube keeps out dust and dirt. This means you clean less and move more materials.

You need to keep the conveyor lined up right. If it gets off track, it can break parts. Check the curves and places where it changes often. Oil the moving parts and look for loose bolts. A good maintenance plan helps your conveyor last longer.

Studies show tube belt conveyors last 10 to 15 years. The table below shows what can change how long they last:

|

Conveyor Type |

Lifespan (Years) |

Conditions Affecting Lifespan |

|---|---|---|

|

Tube Belt Conveyor |

10 to 15 |

Mechanical damage from misalignment and transitions |

|

Conventional Belt Conveyor |

N/A |

N/A |

Tip: Keep your tube belt conveyor lined up and check for damage at curves and changes. This helps it last longer.

Conventional Conveyor Maintenance

Conventional conveyors are often easier to take care of. The open design lets you see problems fast. You can spot worn belts or broken rollers without taking things apart. Cleaning is easy because you can reach all the parts.

Check the belt for fraying and make sure rollers spin well. Tighten loose bolts and change broken parts right away. Dust and dirt can build up, so clean the conveyor often. If you move heavy things, check it more often.

Conventional conveyors do not have a set life like tube belt conveyors. How long they last depends on use and care. Regular checks help stop big problems and keep your conveyor working for years.

Note: Simple care helps you find small problems before they get worse.

Cost Analysis

Investment & Operating Costs

You need to think about both the money you spend at the start and the money you spend to keep your conveyor running. Tube belt conveyors often cost more to buy and install than conventional belt conveyors. The closed design and extra parts make them more expensive. You might pay more for special construction or for fitting the conveyor into tight spaces.

For conventional conveyors, the initial investment is usually lower. Here is what you can expect:

-

Initial investment costs for conventional conveying systems range from USD 1,000 to 3,000 per meter.

-

You also need to pay for construction, supply, and both mechanical and electrical installation.

-

If your project needs complex construction work, the total cost can go up.

Operating costs depend on how much maintenance your system needs. Tube belt conveyors may save you money over time because they need less cleaning and have fewer spills. Conventional conveyors might need more cleaning and repairs, especially if you move dusty or sticky materials.

Tip: Always look at both the starting price and the long-term costs before you choose a conveyor.

Long-Term Value

When you pick a conveyor, you want it to last and work well. Tube belt conveyors often give you better performance in places where you need to control dust or avoid spills. They can also last longer because the closed design protects the belt and the materials inside.

Conventional conveyors work well for simple jobs and cost less at first. If you do not need special dust control or tight routing, they can be a smart choice. You may spend more on repairs and cleaning over time, but the lower starting price helps many businesses.

Think about how long you plan to use your conveyor and what kind of materials you will move. The right choice gives you good value and keeps your operation running smoothly.

Application Suitability

Best Uses for Tube Belt Conveyor

You want your materials to stay safe and your area clean. Tube belt conveyor systems are best when you need to stop dust or spills. These conveyors are used in places that move powders, grains, or chemicals. The closed tube keeps your product and the environment safe. You can use this conveyor where there are sharp turns or steep slopes. It fits in small spaces and helps you follow safety rules.

Here are some times when tube belt conveyor systems work well:

-

Moving bulk things like grains, cement, or minerals

-

Handling sensitive products in food, chemical, or healthcare jobs

-

Carrying materials far with lots of curves

-

Keeping dust and spills away from the environment

Tip: Pick a tube belt conveyor if you need to move bulk materials safely and keep your area clean.

Best Uses for Conventional Conveyor

You see conventional conveyor systems in many places. These conveyors help move boxes, packages, and other things fast. The open belt makes loading and unloading simple. You can use this conveyor for easy layouts and straight paths.

Here are the most common ways to use conventional belt conveyor systems:

-

Automated assembly lines move parts between workstations and make production faster.

-

Warehouses use conveyors to move boxes and packages, making work easier.

-

Food processing and packaging plants move raw materials through each step.

-

Mining and quarrying move large amounts of materials over long distances.

-

Farms use conveyors to move crops and grains.

-

Recycling centers sort and move recyclable materials.

-

Airports use conveyors for moving baggage.

-

Pallet handling systems move pallets in factories and warehouses.

-

Pharmaceutical and chemical jobs use conveyors for safe product transport.

-

Retail and distribution centers move goods between different areas.

Note: Conventional conveyor systems are good for simple jobs and help you move many kinds of products.

You should choose the conveyor that fits your needs. Tube belt conveyor systems keep your materials safe and your area clean. Conventional conveyor systems help you move things fast and work in many industries.

Pros & Cons

Tube Belt Conveyor Pros & Cons

You want to know if a tube belt conveyor fits your needs. This type of conveyor has a unique design that wraps the belt into a tube shape. Here are the main pros and cons to help you decide:

Pros:

-

You get excellent dust control. The closed tube keeps dust inside and stops it from escaping into the air. This helps keep your workspace clean and safe.

-

You avoid spillage. The sealed design holds all materials inside, so you do not lose product along the way.

-

You protect your materials from outside dirt and moisture. The tube design keeps everything inside clean.

-

You can install the conveyor in tight spaces or around sharp corners. The flexible routing helps you fit it into tricky layouts.

-

You reduce the risk of contamination. This is important in food, chemical, and healthcare jobs.

The dust-tight design uses sealed couplings and gaskets. This keeps dust and particles from getting out, which is very helpful in places where cleanliness matters most.

Cons:

-

You face higher production requirements. The conveyor needs special guiding and sealing to form the tube shape.

-

You may see more squeezing force on the material. This can make the conveyor harder to run and use more energy.

-

You might have trouble changing the belt. If the belt edges get caught in the rollers, it can cause damage.

-

You pay more at the start. The closed design and extra parts make it more expensive than a standard belt conveyor.

You need to check the conveyor often to keep it running well, especially at curves and changes in direction.

Conventional Conveyor Pros & Cons

A conventional conveyor uses a flat, open belt. This is the type you see most often in factories and warehouses. Here are the main pros and cons:

Pros:

-

You spend less money at the start. The simple design costs less to buy and install.

-

You find it easy to load and unload materials. The open belt lets you move boxes, bags, and other items quickly.

-

You can spot problems fast. The open design makes it easy to see worn belts or broken rollers.

-

You save on maintenance. Regular checks and simple repairs help you avoid big problems and keep costs down.

-

You get a longer equipment life with good care. Preventive maintenance keeps the conveyor running and reduces the need for new parts.

|

Benefit |

Description |

|---|---|

|

Minimizing Downtime and Repair Costs |

Preventive maintenance keeps your conveyor working and avoids costly repairs. |

|

Extending Equipment Lifespan and ROI |

Regular care helps your conveyor last longer and gives you more value for your money. |

Cons:

-

You may have more spillage. The open belt lets materials fall off, especially at transfer points.

-

You deal with more dust. Moving dry materials creates airborne dust, which can be harmful and hard to control.

-

You might face safety and compliance problems. Spillage and dust can make your workspace unsafe and break safety rules.

-

You spend more time cleaning. Dust and spills mean you need to clean the conveyor and the area around it more often.

-

You may need extra covers or dust control systems. These add to your costs and make the system more complex.

Spillage and dust are common issues with conventional conveyors. You need to plan for extra cleaning and safety checks.

Quick Comparison Table

|

Feature |

Tube Belt Conveyor |

Conventional Conveyor |

|---|---|---|

|

Dust Control |

Excellent |

Poor to Moderate |

|

Spillage Prevention |

Excellent |

Poor to Moderate |

|

Initial Cost |

High |

Low |

|

Maintenance |

Moderate (specialized) |

Easy (simple checks) |

|

Flexibility |

High (tight spaces, curves) |

Moderate (straight, gentle curves) |

|

Cleaning Needs |

Low |

High |

Choose a tube belt conveyor if you need top dust and spillage control. Pick a conventional conveyor for simple jobs and lower costs.

Selection Guide

Key Decision Factors

Choosing the right conveyor system for your facility can feel overwhelming. You want to make sure your choice matches your needs, space, and budget. Start by looking at the most important factors that affect your decision. The table below shows what you should consider:

|

Decision Factor |

Description |

|---|---|

|

Equipment Reliability |

A well-designed conventional conveyor can last over 20 years without needing a belt replacement. |

|

Operating Costs |

Conventional systems usually have lower operating costs than cable or tube systems. |

|

Maintenance Requirements |

Maintenance needs can differ a lot between conveyor types. This affects your long-term costs. |

|

Power Consumption |

Energy efficiency changes how much you spend to run your conveyor every day. |

|

Application Needs |

Think about what you need to move, how much, and the path it must travel. |

You also need to think about space and the type of material you want to move. Larger belts need more room. If your facility has tight spaces, a tube system might fit better. The kind of material you move matters too. Some materials need gentle handling or special dust control.

Tip: Always match the conveyor type to your material and space needs. This helps you avoid problems later.

Practical Checklist

You can use a step-by-step checklist to help you pick the best conveyor for your job. Follow these steps to make a smart choice:

-

Identify the Material

Write down what you need to move. Think about the size, weight, temperature, and if it is dusty or sticky. -

Check the Environment

Look at where you will install the conveyor. Note if the area is hot, cold, wet, or dusty. Some systems work better in tough conditions. -

Measure Your Space

Measure the area where you want to put the conveyor. Make sure you have enough room for the belt width and any turns or slopes. -

Calculate Capacity and Speed

Decide how much material you need to move and how fast. This helps you pick the right motor strength and system size. -

Review Maintenance Needs

Think about how often you can check and fix the conveyor. Tube systems may need special care at curves. Open systems are easier to inspect. -

Plan for the Future

Choose a system that can grow with your business. Look for modular designs that let you add or change parts later. -

Check Safety and Compliance

Make sure the conveyor meets safety rules and any import-export certifications you need. -

Compare Costs

Look at both the starting price and the long-term costs. Higher initial costs may save you money over time if the system is more reliable or efficient. -

Pick a Trusted Supplier

Work with a supplier who knows your industry. They can help you choose the right system and offer support if you need changes later.

Note: Think about conveyors early in your project. This helps you get the most value and avoid costly changes later.

By following this checklist, you can find a conveyor system that fits your needs, space, and budget. You will also avoid common problems like poor fit, high maintenance, or wasted energy. Take your time and review each step before making your final choice.

You now know the big differences between tube belt and conventional conveyors. Picking the best one depends on what you need at work, your workspace, and your industry rules. Look at the table below to help you choose:

|

Factor |

Description |

|---|---|

|

Operational Needs |

Make sure the system fits your daily jobs |

|

Environmental |

Check things like heat, wetness, and sunlight |

|

Industry Requirements |

Pick features that match your type of work |

|

Additional Features |

Think about speed, power, and how to fix it |

To get started, look at your current machines. Write down when they stop working. Ask your team where problems happen. Talk to suppliers for help with material type, how strong it is, and if it costs more or lasts longer.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported