Industry reports show some new trends are changing corrosion-resistant enclosed tube belt conveyor technology.

-

IoT helps things work better by giving real-time updates.

-

Automation and AI help machines change fast and grow quickly.

-

People are trying to save energy and use greener materials.

|

Aspect |

Impact |

|---|---|

|

Sustainability |

Green actions can cut carbon footprints by up to 40%. |

|

Efficiency |

Lighter designs use 15% less energy. |

|

Safety |

Better safety features lower accidents by 25%. |

|

Adaptability |

Digital twins will be used by 70% of big industries by 2025. |

People who work in the industry should keep learning and act fast. New ideas in conveyor technology need people to watch these trends.

Smart Tech Trends in Tube Belt Conveyor Systems

AI and Predictive Maintenance

Artificial intelligence is changing how these systems work. AI checks belt tracking, bearing health, and motor performance. It also looks for alignment problems. Predictive maintenance uses this data to plan repairs early. This helps stop breakdowns before they happen. Downtime drops by up to 70%. Belt life can be 50% longer. Companies like BMW and Shell have seen big improvements. BMW stopped over 500 minutes of yearly disruption. Shell saved about $2 million by finding problems early. These trends mean fewer surprise stops and lower costs. Equipment lasts longer. AI also finds product defects. This makes customers happier and improves quality.

|

Implementation Aspect |

Description |

|---|---|

|

Monitoring |

AI checks belt and motor health and finds problems early. |

|

Downtime Reduction |

Predictive maintenance can lower downtime by 70%. |

|

Belt Life Extension |

Fixing things on time makes belts last 50% longer. |

IoT and Real-Time Monitoring

IoT brings real-time monitoring to conveyor systems. Sensors collect and send data about the system’s condition. This gives instant alerts if something is wrong. Plants using IoT have less unplanned downtime, up to 40% less. Smart conveyor systems use this data to save energy and work better. Remote access means fewer trips to the site. This saves time and money. IoT also helps look at old data. This helps with planning and future spending.

|

Benefit |

Description |

|---|---|

|

Reduced Downtime |

Real-time monitoring stops small problems from getting worse. |

|

Energy Savings |

Smart systems use less energy and cut costs. |

|

Better Productivity |

IoT automation can boost output by 15%. |

Digital Twins for Optimization

Digital twins are virtual models of conveyor systems. Engineers use them to test changes and see results. They do not need to touch the real equipment. This helps companies try new ideas and meet new needs. Digital twins make it easier to design systems for the future. They help with both efficiency and sustainability. These trends help companies stay ahead. They use new technology for better performance.

Note: Companies that use new conveyor solutions and automation will lead in conveyor belt technology.

Sustainability Innovations in Belt Conveyor Systems

Eco-Friendly Materials

Many companies want to help the planet. They pick eco-friendly materials for belt conveyor systems. Recycled rubber compounds help cut down on landfill waste. This also means fewer new resources are needed. Bio-based polymers come from plants. These are good for lighter jobs. Energy-efficient fabrics use less power. This helps machines work better. These changes show companies care about the earth and their business.

-

Recycled rubber compounds help keep trash out of landfills.

-

Bio-based polymers are made from plants that grow again.

-

Energy-efficient fabrics help machines use less energy.

Energy-Saving Designs

Energy-saving designs are important for new belt conveyor systems. Tubular drag conveyors move slower and make less friction. This means they use less power. New conveyor designs can save almost 28% more energy. This also lowers carbon dioxide by over 5,000 tons each year. These changes help companies save money and reach digital goals.

-

Tubular drag conveyors use about 5 HP, much less than old ones.

-

New systems help cut energy use and lower pollution.

Reducing Environmental Impact

Sustainability changes in belt conveyor systems do more than save energy. Companies swap old systems for lighter and better technology. Lighter electric motors and strong materials help machines last longer. This means less damage and fewer repairs. These changes lower greenhouse gases and help the world. Many companies work with suppliers who use eco-friendly rules and local materials. They also set goals with the Science-Based Targets Initiative. They share progress under the Corporate Sustainability Reporting Directive.

|

Environmental Benefit |

Description |

|---|---|

|

Big Drop in Carbon Emissions |

Truckless systems use less diesel and more electric power, often from clean sources. |

|

Less Soil Damage and Erosion |

These systems protect soil by needing fewer roads, stopping erosion, and helping plants grow. |

|

Less Noise and Air Pollution |

Enclosed conveyors and rail-veyors make less noise and dust than trucks, so air is cleaner and workers stay healthy. |

|

Better Water and Energy Use |

Truckless systems save water by needing less dust control and use energy wisely, helping save resources. |

These new trends help companies follow rules and global goals. They also make work easier and save money.

Automation and Adaptability in Tube Belt Conveyor Technology

Automated Operations

Automation is a big part of new conveyor systems. Companies use robots and automation to make work easier. Robotic arms and PLCs do jobs people used to do. These machines help things be more accurate and make fewer mistakes. Sensors check every step to make sure it is right. Real-time analytics help spot problems fast. Automated welding lines measure welds and stop if something is wrong. This helps save money by cutting waste and fixing mistakes early. In refrigerator factories, automated lines keep products safe and good quality. These new tools help companies work better and safer.

-

Robotic arms and PLCs help make fewer mistakes.

-

Sensors and analytics find problems before things break.

-

Automated lines help products stay safe and good.

Customization for Applications

Belt conveyor systems can be changed for different jobs. Eco-friendly enclosed tube belt conveyors work for food, nuts, pet food, and other materials. Companies can ask for special sizes or extra protection. Some conveyors work with hard products or in tough places. Branding choices like colors or logos are possible too. These new conveyor ideas help companies do their jobs better and faster.

|

Benefit |

Description |

|---|---|

|

Adaptability to Different Materials |

Custom conveyors move many materials safely and keep them good. |

|

Enhanced Efficiency and Productivity |

Special conveyors help work go faster and stop delays. |

|

Scalability for Industry Changes |

Custom systems can change as companies grow or needs change. |

|

Integration with Existing Systems |

Custom conveyors fit with old systems and keep work smooth. |

|

Cost-Effectiveness |

Saving money over time makes the first cost worth it. |

Flexible and Modular Designs

Flexible and modular designs are important for new conveyor systems. Modular conveyors can be changed or made bigger easily. Companies can change layouts fast for new products or rules. Food packaging lines with modular systems clean up and switch faster. Adaptive conveyors move different products with speed and direction changes. Lighter and stronger materials make systems more flexible and save energy. Smart sensors and IoT help watch and improve systems in real time. These changes help companies save energy and work better. Digital twins and new tech make conveyor systems even more adaptable.

Note: Flexible and modular conveyor systems help companies change quickly and work better.

Enhanced Safety and Efficiency Trends

Advanced Safety Features

Modern belt conveyor systems have new safety features. These features protect workers and help things run better. Speed and load monitoring systems send alerts right away if something is wrong. If the conveyor goes too fast or carries too much, workers know quickly. Emergency shut-off buttons let workers stop the conveyor fast if there is a problem. Start-up warning systems use lights and sounds to warn people before the conveyor moves. These features help stop accidents and keep everyone safe.

|

Safety Feature |

Description |

|---|---|

|

Speed and Load Monitoring |

Sends alerts if speed or load is not safe. This helps keep workers safe and makes work better. |

|

Emergency Shut-off Mechanisms |

Lets workers stop the conveyor right away if something blocks it. This can stop bad injuries. |

|

Start-up Warning Systems |

Uses lights and sounds to warn workers before the conveyor starts. This helps stop accidents. |

Getting new models with these features helps stop accidents from mistakes or broken parts. Companies that care about safety have cleaner and safer places to work. They also get more done. In places without these features, more than 30% of workers get hurt each year. Training and using safety gear also help lower risks.

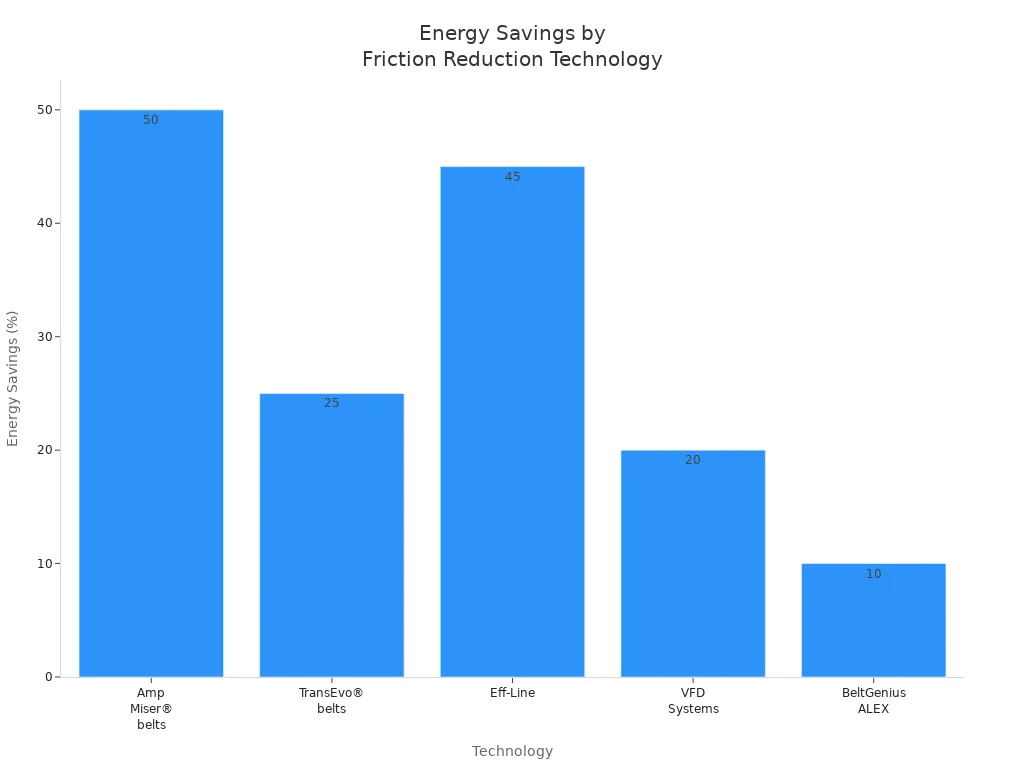

Friction Reduction and Energy Loss

Cutting down friction is a big trend in tube belt conveyor technology. Low rolling resistance belts use less energy than regular belts. They can save between 10% and 40% energy. The bottom part of the belt matters most for saving energy. Picking the right material is important. Cleaning, oiling, and tightening parts often also help lower friction. Using smooth materials like PVC belts saves even more energy.

|

Technology |

Energy Savings [%] |

Best Application Context |

Implementation Complexity |

Key Benefits |

Main Limitations |

|---|---|---|---|---|---|

|

Amp Miser® belts |

Up to 50% |

Long conveyors, indoor |

Low |

Less friction, longer belt life |

Not good for tough places |

|

TransEvo® belts |

Up to 25% |

Mining |

Medium |

Lower rolling resistance, lighter |

Costs more, best for mining |

|

Eff-Line |

Up to 45% |

Indoor conveyors |

Low |

Less sliding resistance |

Not for heavy loads or outside |

|

VFD Systems |

Up to 20% |

High-capacity, variable load |

High |

Controls speed, less wear |

Costs more at first, harder to set up |

|

BeltGenius ALEX |

~10% |

Long conveyors, mining |

Medium |

Finds problems, makes belts last |

Needs sensors put in |

Soft conveying systems move things slowly and gently. This means less breakage and less energy used. These ideas help companies save energy and help the planet.

Worker-Friendly Innovations

Worker-friendly changes make belt conveyor systems easier to use. Adjustable conveyor heights let workers pick a good height. This helps stop back and neck pain. Ergonomic workstations have good lights, space for tools, and mats that help feet feel better. Lift-assist devices help workers move heavy things with less effort. Visual and sound signals make controls easy to use and safer.

|

Innovation Type |

Description |

|---|---|

|

Adjustable Conveyor Heights |

Lets workers change the height to stop back and neck pain. |

|

Optimal Reach Zones |

Keeps things close so workers do not have to stretch too much. |

|

Inclination and Tilt Features |

Uses gravity to help move things, so workers do not have to lift as much. |

|

Automated Solutions |

Machines move heavy or odd-shaped items so workers do not have to. |

|

Anti-Fatigue Measures |

Mats help workers feel better when standing for a long time. |

Companies that change workstations and use ergonomic tools see happier workers and fewer injuries. One plant had 90% fewer injuries and faster setups after adding these systems. These trends show that making workers comfortable helps them do better work and feel good. Getting and keeping good workers is important, and these changes make work a better place.

Tip: Spending money on safety and comfort helps workers and makes work faster and greener.

The Future of Conveyor Technology: Market Growth and Industry Impact

Market Drivers and Demand

The world market for belt conveyor systems is getting bigger. In 2024, it was worth $5.56 billion. By 2029, it should reach $6.86 billion. This means it grows about 4.8% each year. Asia-Pacific is the biggest market. Western Europe is growing the fastest. Many things make people want better tube belt conveyor systems:

-

More factories and online shopping need good ways to move things.

-

Smart conveyor systems use IoT and AI to help work faster.

-

Safety at work and following rules are very important.

-

Mining, cement, and food companies need strong conveyor systems.

-

Online shopping means warehouses need quick and correct delivery.

-

Automated storage and retrieval systems help things move fast.

Integration of New Technologies

Companies spend money on new technology to stay ahead. Using IoT and automation in conveyor systems helps work better and keeps customers happy. Making new products and caring about the planet helps meet rules and what people want. Automation and smart sensors help companies do a better job and change with new trends. Saving energy and making less pollution helps the world.

Preparing for Future Trends

Industry leaders get ready for new trends by doing these things:

-

Use motors that save energy and braking systems that give power back.

-

Pick modular designs so production lines can change and grow.

-

Make work safer with new safety tools and comfy features.

-

Add robots and automation to do jobs faster and with less work.

-

Use smart sensors to watch systems and fix problems before they happen.

-

Always try to save energy and make less pollution in every part of work.

Tip: Companies that use automation, modular designs, and care about the planet will be the best in belt conveyor systems.

Industry leaders notice new trends changing cold-resistant tube belt conveyor for mining in Arctic technology. Smart systems, green materials, and safety features help companies do better. Companies that use new ideas can succeed for a long time. They should look at their conveyor systems now and plan upgrades.

Learning about new trends helps teams stay ahead.

Next Steps:

-

Check what technology you have now

-

Make simple upgrade plans

-

Teach workers how to use new systems

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported