When you pick a jaw crusher for your project, you should think about some important things. The type of material is very important. You may work with limestone, granite, or basalt. Capacity and size decide how much rock you can crush. Output size changes what your final product looks like. Mobility lets you move the machine where you want. Durability helps your machine last longer. Your budget helps you choose what you can buy. This guide helps you match crusher features to your needs.

Key Takeaways

-

Pick a jaw crusher based on what you will crush, like granite or limestone. This helps the machine work well.

-

Think about the size and capacity of the jaw crusher. Make sure it can crush the rocks you have. It should fit your project’s needs.

-

Find a jaw crusher made from strong materials. A tough machine lasts longer. It also needs less fixing, which saves you money.

-

See if the jaw crusher can move easily. Mobile crushers can go to different job sites. This saves time and money on moving them.

-

Always match the jaw crusher's output size to your project. This helps you get the right material for your work.

Jaw Crusher Basics

What Is a Jaw Crusher

A jaw crusher breaks big pieces into smaller ones. It has two jaws. One jaw does not move. The other jaw moves in a circle shape. The moving jaw pushes material against the still jaw. This crushes the material inside a V-shaped space. When the moving jaw goes back, a gap opens at the bottom. Crushed pieces fall through this gap. You can change the gap to pick the output size. A heavy flywheel helps the moving jaw move smoothly. This design lets you crush hard and rough materials like rock. It works fast and well.

Role in Construction and Mining

Jaw crushers are used in many jobs. You see them in mining, recycling, and building work. They help break down things like concrete, asphalt, and ore. Jaw crushers are often the first machines used. They get material ready for other crushers. This helps work go faster.

Tip: Pick a jaw crusher if you need to crush tough stuff quickly and safely.

In building, jaw crushers crush concrete and bricks. They help make roads and bridges. More jaw crushers are needed as cities grow and new projects start. In mining, jaw crushers break big rocks and ore. This step is needed before more work can be done. It helps get minerals and metals for the world.

Types of Rock Crusher

When you begin a project, you should know about the types of rock crusher. Each type is good for certain jobs and materials. There are jaw crushers, cone crushers, gyratory crushers, impact crushers, and hammer crushers. These machines break rocks into smaller pieces.

Compressive Crushers

Compressive crushers crush rock by squeezing it. Jaw crushers and cone crushers are in this group. They work well with hard and rough materials. You can change the output size by adjusting the settings. The table below shows how compressive crushers and impact crushers are different:

|

Feature |

Compressive Crushers |

Impact Crushers |

|---|---|---|

|

Mechanism |

Uses squeezing force |

Uses hitting force |

|

Suitable Materials |

Harder, rough materials |

Softer, less rough materials |

|

Output Characteristics |

Bigger, more jagged pieces |

More even sizes, cube shapes |

|

Reduction Ratio |

Usually lower |

Usually higher |

|

Control over Output |

More control, can adjust settings |

Less control over shape |

If you need to crush hard rocks like basalt or granite, compressive crushers work better.

Impact Crushers

Impact crushers break rock with a fast-moving part. These machines are best for softer and less rough materials. They make more even and cube-shaped pieces. Impact crushers help with fine crushing and shaping. You might use them after a jaw crusher to get the size and shape you want.

Choosing the Right Crusher

You need to think about a few things when picking a crusher. Look at how hard, wet, and rough the material is. Check the size of the rocks you put in and the size you want out. Think about how much you want to shrink the rock and how much you need to crush. The table below shows which crushers are best for hard rock:

|

Hard Rock Type |

Rock Hardness (Mohr's Scale) |

Suitable Crushers |

Crushing Process Overview |

|---|---|---|---|

|

Basalt |

5-7 |

Jaw crusher, cone crusher, impact crusher |

Start with jaw crusher, then cone crusher, finish with impact crusher. |

|

River Pebble |

7 |

Jaw crusher, cone crusher, impact crusher, sand maker |

Start with jaw crusher, then cone crusher, finish with impact crusher or sand maker. |

|

Granite |

6-7 |

Jaw crusher, impact crusher, cone crusher, sand maker |

Start with jaw crusher, then impact or cone crusher, finish with sand maker. |

Note: Always match the crusher to the rock type and the crushing stage. This helps you get the best results and saves money.

When you look at the types of rock crusher, you see each one is best for certain materials and steps. Picking the right crusher makes your job easier and faster.

Jaw Crusher Selection Factors

Material Hardness

Material hardness is very important when picking a jaw crusher. Hard rocks like granite and basalt need more force to crush. This makes the crusher work harder and wears out the jaw plates faster. Softer stones like limestone are easier to crush. The machine lasts longer and needs less fixing.

-

Jaw crushers wear out faster with granite and basalt than with limestone.

-

Hardness changes how often you replace jaw plates and liners.

-

Hard rocks need more power, which can lower how well the crusher works.

-

Rocks with higher compressive strength wear out parts faster.

If you work with hard rocks, you need strong crushers. Jaw crushers and cone crushers are good for these jobs.

Abrasiveness

Abrasiveness means how much a rock can wear down crusher parts. Some rocks, like those with lots of quartz, are very abrasive. This can make your jaw crusher last 30% to 50% less time. If you crush abrasive rocks often, pick a jaw crusher made for tough jobs.

-

Jaw crushers are strong and work well with abrasive rocks like granite, basalt, and ores.

-

They are easier to move than other types, so you can use them in different places.

-

Jaw crushers are the most popular choice for abrasive rocks.

Picking the right crusher for abrasive rocks saves money on repairs and helps your machine last longer.

Feed Size

Feed size is the size of rocks you put in the jaw crusher. The machine works best when the biggest rock is about 80% of the crusher’s opening. For example, if your crusher has a 30-inch opening, the largest rock should be about 24 inches. This stops clogging and keeps the crusher working well.

Jaw crushers can take feed sizes from 40 mm up to 1200 mm. Big primary crushers are needed for large rocks in mining.

Output Size

Output size is how big the crushed rocks are after crushing. You can change the jaw crusher to get the size you want. The right setting, called CSS, controls how much material goes to the next step.

"The right jaw crusher CSS helps the rest of the crushing process. It lets the primary jaw make material that is good for secondary crushing."

"Make sure your crusher’s CSS can make the sizes you want and still work well. Tighter CSS settings lower capacity, so plan for that."

Always match the crusher’s output size to what you need for your project. This helps you get the right material for your job.

Capacity

Crushing capacity tells you how much the jaw crusher can crush in one hour. Pick a crusher that fits your project’s needs. If you work in big mining or construction, you may need a machine that can crush over 100 tons per hour.

|

Model Type |

Capacity Range (TPH) |

|---|---|

|

Laboratory |

0.550 – 3.0 |

|

Major Applications |

4.5 – 1,000 |

Feed sizes can be from 40 mm to 1200 mm. Some jaw crushers weigh over 30 tons and are used for big jobs. Always check the crushing capacity before you choose a crusher.

Mobility

Mobility matters if you need to move your jaw crusher. Mobile crushers help you reach faraway sites and lower transport costs. You can crush rock right at the site, which saves time and money.

-

Mobile crushers let you work in remote quarries and mines.

-

They let you crush new rocks right away, so you don’t have to haul them.

-

Mobility can lower transport costs by up to 30% of your total budget.

If your project moves a lot or is far away, a mobile jaw crusher is a smart pick.

Durability

Durability means how long your jaw crusher lasts and how well it works with tough jobs. You want a machine that runs a long time without breaking. Look for these features:

|

Feature |

Description |

|---|---|

|

Robust Construction |

Built to handle strong forces and tough conditions, so there is less downtime. |

|

High-Quality Materials |

Uses manganese steel, cast iron, and alloys for strength and to resist wear. |

|

Optimized Toggle Plate |

Helps the crusher handle more material and lowers stress on parts. |

|

Maintenance Accessibility |

Easy-to-remove side plates and simple lubrication points make fixing faster. |

|

Safety Features |

Keeps workers safe and lowers the chance of accidents. |

A durable jaw crusher works better and saves money on repairs.

Budget

Your budget decides which jaw crusher you can buy. Prices change based on the type and size of the machine. Here is a table to help you compare:

|

Jaw Crusher Type |

Price Range |

|---|---|

|

Single Toggle Jaw Crushers |

$10,000–$100,000 |

|

Double Toggle Jaw Crushers |

$50,000–$200,000+ |

|

PE Jaw Crushers |

$15,000–$150,000 |

|

PEX Jaw Crushers |

$10,000–$100,000 |

Think about your budget, but also look at how well the crusher works, how long it lasts, and the size of the finished product. Sometimes, spending more at first gives you better results and lower costs later.

Tip: Always match the jaw crusher to your material, crushing capacity, and desired output. Picking the right crusher for your needs will help your project work better and give you the finished product size you want.

Comparing Jaw Crusher to Other Types

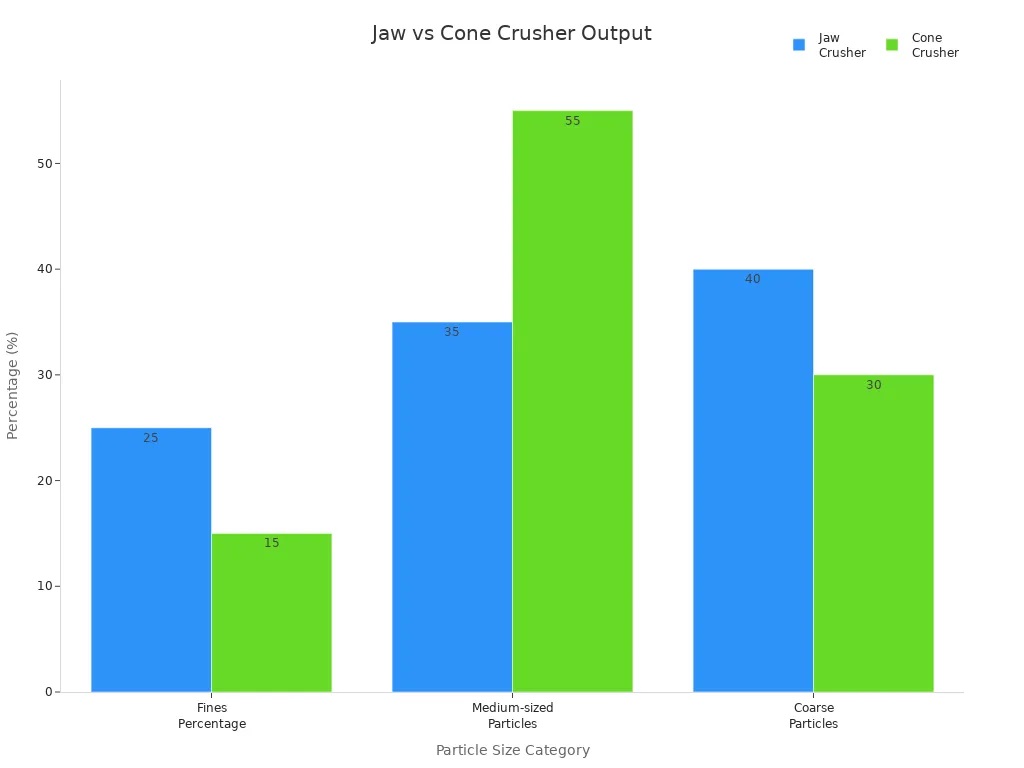

Jaw vs. Cone Crusher

You may wonder how jaw crushers compare to cone crushers. Both machines help you break down large stones, but they work best in different situations. Jaw crushers use a simple motion to crush material between two plates. Cone crushers use a spinning cone inside a bowl to squeeze the material.

Here is a table to help you see the main differences:

|

Feature |

Jaw Crusher |

Cone Crusher |

|---|---|---|

|

Material Suitability |

Hard and abrasive stones (e.g., granite, basalt) |

Medium-to-hard materials (e.g., limestone, dolomite) |

|

Feed Size Capability |

150-1,000 mm (6-40 inches), up to 1,500 mm (60 inches) |

Up to 250 mm (10 inches), some models up to 350 mm (14 inches) |

|

Output Size Uniformity |

Broader variety of particle sizes |

More uniform and cubical product |

|

Fines Percentage |

20-30% |

10-20% |

|

Medium-sized Particles |

30-40% |

50-60% |

|

Coarse Particles |

30-50% |

20-40% |

You can see that jaw crushers handle bigger feed sizes. They work well with hard rock and produce a mix of particle sizes. Cone crushers give you a more even product, which helps if you need a certain size for your project.

Tip: Use a jaw crusher when you need to break down large, hard stones. Pick a cone crusher if you want a more uniform size and work with medium-hard materials.

Jaw vs. Impact Crusher

Jaw crushers and impact crushers both help you crush material, but they do it in different ways. Jaw crushers use pressure to break down large pieces. Impact crushers use fast-moving parts to hit and shatter the material.

Here are some reasons to choose a jaw crusher over an impact crusher:

-

You can process very large feed sizes, even boulders up to one cubic meter.

-

Jaw crushers give you a high reduction ratio, up to 8:1, so you can make big rocks much smaller in one step.

-

These machines last a long time and need less maintenance.

-

You save money on repairs and running costs.

-

Jaw crushers work well with large, tough material.

Impact crushers work best for softer materials and when you want a more even, cube-shaped product. They are often used after a jaw crusher to get the final size you need.

Note: If you need to crush hard rock or large stone at the start of your project, a jaw crusher is the better choice.

When to Choose Jaw Crusher

You should pick a jaw crusher when you need to handle large, hard materials. Mining projects often use jaw crushers first because they can break down tough rock like granite and basalt. These machines work well in the primary crushing phase, where you need to reduce the size of big stones before moving to other crushers.

Choose a jaw crusher if:

-

Your material is hard or abrasive.

-

You need to crush large pieces at the start.

-

You want a machine that lasts a long time and is easy to maintain.

-

Your project needs a mix of particle sizes for further processing.

Jaw crushers give you a strong start in your crushing process. They help you save time and money by handling the toughest jobs first.

Buying Tips

Manufacturer Evaluation

When you pick a jaw crusher, choose a trusted company. You should check a few things before you buy. The table below shows what to look for:

|

Criteria |

Description |

|---|---|

|

Compatibility |

Make sure the parts fit with your other machines. |

|

Material Durability |

Choose machines made from strong stuff like manganese steel. |

|

Customer Reviews |

Read what other buyers say to see if the company is good. |

|

Warranties and Support |

Ask about warranties and help after you buy. |

|

Supplier Certifications |

Look for certificates like ISO 9001 to show quality. |

|

Geographical Location |

Think about shipping costs and how long delivery takes. |

|

Quality Control |

Check if the company uses good quality checks and keeps clear records. |

Tip: A good company helps you pick the right jaw crusher and gives help after you buy it.

Maintenance Needs

You need to take care of your jaw crusher to keep it working well. Regular checks help your machine last longer and stay safe. Here are some common things to do:

-

Look at flywheels to see if they move right.

-

Make sure jaw die bolts are tight.

-

Check the toggle plate position.

-

Grease bearings as the maker says.

-

Make sure drive belts are tight enough.

-

Listen for weird sounds when the machine runs.

-

Watch the hydraulic pressure gauge.

-

Check the amp gauge for electric parts.

-

Keep flywheel RPM in the right range.

-

Look at the pitman assembly for movement.

-

Check for uneven wear on jaw dies and fix feeding.

-

Flip or swap jaw dies to make them last longer.

-

Change cheek plates when needed.

Doing these steps helps you avoid expensive repairs and keeps your crusher working well.

Safety Features

Safety is very important when you use big machines. Jaw crushers need special safety parts to keep you and your team safe. The table below lists key safety features:

|

Safety Feature |

Description |

|---|---|

|

Audible/Visual Alarms |

Alarms warn you before the crusher starts. |

|

Material Feed |

Feed material evenly and do not overload the machine. |

|

Guarding & Isolation |

Guards must stay on; never go inside while it runs. |

|

Continuous Monitoring |

Watch for dust, noise, and other dangers. |

|

Lockout/Tagout (LOTO) |

Turn off all power before fixing or checking the machine. |

|

Clearing Blocked Crushers |

Always shut down before clearing jams. |

|

Maintenance & Adjustment Safety |

Use strong supports and certified lifting tools. |

|

Clear Communication |

Set up clear signals and rules for everyone working with the crusher. |

|

Incident Reporting |

Tell someone about any close calls or accidents to make things safer. |

|

Continuous Improvement |

Go over safety rules often and talk about safety with your team. |

Always check safety parts before you start working with rocks.

Purchase Checklist

Before you buy a jaw crusher, use a checklist. This helps you get the right machine for your job and size needs.

-

Jaw Plates: Check for wear and see if you need new ones.

-

Bearings: Look for damage or looseness.

-

Toggle Plate and Seat: Make sure they line up and are not worn.

-

Eccentric Shaft: Check for damage or misalignment.

-

Flywheel: Look for balance and wear.

-

Hydraulics: Test for leaks and correct pressure.

-

Drive System: Check motor, belts, and pulleys for tension and alignment.

-

Clearance and Adjustment: Confirm all settings and test adjustment parts.

-

Electric: Inspect wiring, switches, and control panels.

-

Safety Items: Make sure guards and emergency stops work.

-

Functional Test: Run a test with material to see how the machine performs.

Use this checklist to make sure your crusher fits your needs and works safely.

Picking the best heavy duty jaw crusher means you need to know about your material. Check if it is hard, rough, or has big pieces. Match the crusher’s feed opening, how much it can crush, and motor power to your job. Always use a checklist before you buy:

-

Look at jaw plates and bearings for damage.

-

Test the hydraulics and drive system to see if they work.

-

Make sure all safety features are working.

Ask trusted suppliers for help and advice. Picking carefully helps you save money and makes sure your crusher works well for a long time.

|

Benefit |

Description |

|---|---|

|

Versatility |

Works with many kinds of materials easily. |

|

Maintenance |

Costs less and does not break down as much. |

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported