You can make an environmentally friendly choice for moving bulk materials by using environmentally friendly enclosed tube belt conveyors. The closed and waterproof design keeps materials inside, preventing spills and dust from escaping. This method of transportation helps you comply with stringent environmental regulations like ISO 14001 and contributes to green extraction, showcasing its environmental benefits.

|

Criteria |

Tube Belt Conveyors |

Traditional Conveyors |

|---|---|---|

|

Material Spillage |

Zero spillage |

Higher risk |

|

Dust Control |

Excellent |

Needs extra suppression |

-

You get a cleaner place to work, enhancing the environmental benefits.

-

The system prevents contamination and keeps your workplace safe, further supporting eco-friendly practices.

How Enclosed Tubular Conveyor Systems Work

Key Features of Tube Belt Conveyors

Tube belt conveyors keep materials safe and clean. The belt and materials stay inside a tube. This protects the product and the environment. Dust and spillage do not escape into your building or outside. The tube keeps out germs and other bad things. Your materials stay pure.

-

The tube conveyor stops outside germs from getting in.

-

You lower the chance of contamination from sprays or nearby machines.

-

The system makes a controlled space. This means things stay clean for longer.

-

Wet cleaning is easier. You do not get water everywhere, so cleaning works better.

-

You can set up cleaning to run by itself. This helps keep germs away.

-

In food processing, like frozen foods, the tube design stops contamination and makes cleaning easy.

Tubular conveyors have smart features. They use dust control at places where you load and unload. The tube keeps materials safe. You do not lose product or make a mess.

Comparison to Conventional Conveyor Belts

You may wonder how modular enclosed tube belt conveyors are different from regular open systems. The differences are easy to see when you look at what they do and how they help the environment.

|

Feature |

Tubular Belt Conveyors |

Conventional Belt Conveyors |

|---|---|---|

|

Design |

Materials go inside a tube |

Belt is open |

|

Spillage Prevention |

Stops spillage |

Materials can spill |

|

Routing Options |

Can go up steep paths |

Routing is limited |

|

Durability |

Lasts longer because of tube |

Durability is lower |

|

Efficiency |

Works better |

Works okay |

|

Criteria |

Enclosed Tube Belt Conveyors |

Conventional Conveyor Belts |

|---|---|---|

|

Environmental Impact |

Less leakage and pollution |

More cleaning needed |

Tube belt conveyors protect your materials and the environment better. Pipe conveyor technology lets you move materials in more ways and lasts longer. You also make less pollution and do not need to clean as much.

Environmental Benefits of Enclosed Tube Belt Conveyors

Spillage and Dust Reduction

Tube belt conveyors help the environment by stopping spills and dust. The closed-trough design keeps materials inside all the time. This means you do not lose product and your site stays clean. The tube shape works like a wall to block spillage.

-

Tube belt conveyors move things gently, so less dust goes into the air.

-

These systems do not blow air fast, so you do not get dust clouds.

-

Most of the time, you do not need extra dust control because the system already stops dust from escaping.

You help nature by making less dust. Workers do not breathe in bad particles. Closed-trough conveyor belts keep materials clean, so there is less dust and a healthier place to work.

Tip: Using closed-trough conveyor belts can stop thousands of tons of dust from going into the air every year. This is a big help for the environment in bulk material handling.

Workplace Safety and Regulation Compliance

Tube belt conveyors make your workplace safer and help you follow rules. Closed-trough conveyor belts give materials a sealed path. This keeps your work area clean and safe. You lower the chance of accidents from spills or dust in the air.

-

You can follow FDA rules that keep bad things out of your product.

-

You meet USDA standards for safe food handling.

-

You follow 3-A Sanitary Standards, which matter for food processing.

Closed-trough conveyor belts help you avoid fines and shutdowns. You show you care about the environment by following these rules. Clean transport and better protection make your workplace safer for everyone.

Waterproof and Contamination Prevention

Tube belt conveyors have a waterproof design that helps the environment. Closed-trough conveyor belts keep out rain, sun, and dirt. This keeps your materials dry and pure. You do not worry about water or dirt getting in.

|

Feature |

Benefit |

|---|---|

|

Enclosed tubular structure |

Stops outside dirt from mixing with materials |

|

Protection from environmental factors |

Keeps materials safe from rain and sun |

|

Minimizes leakage and spillage |

Lowers risk of contamination and meets protection rules |

-

The system blocks dust and tiny particles in the air.

-

It keeps out dirt, water, and germs, which is important for food and farming.

-

In chemical and medicine work, the design stops dangerous powders and toxins from getting out.

You get less spillage and better protection with every load. Closed-trough conveyor belts use tubular conveyor technology to keep your product safe from start to finish. You help the environment and make the world cleaner and safer.

Energy Efficiency and Sustainability

Lower Power Consumption

Tube belt conveyors help you use less energy at work. They have special idlers and a closed design. This means you do not need as much power to move things. You save energy every time you move a ton of material. You get good results while using less electricity.

|

Design Feature |

Contribution to Power Consumption |

|---|---|

|

Specially designed idlers |

Use less energy for each ton moved |

|

Return of material through |

Closed design uses less energy |

Spillage-free enclosed tube belt conveyors help you protect the climate. You use less electricity, so you pay less and help the earth. The closed tube keeps materials safe and moves them gently. This gentle way saves energy and keeps your product safe. Over time, you save a lot of energy.

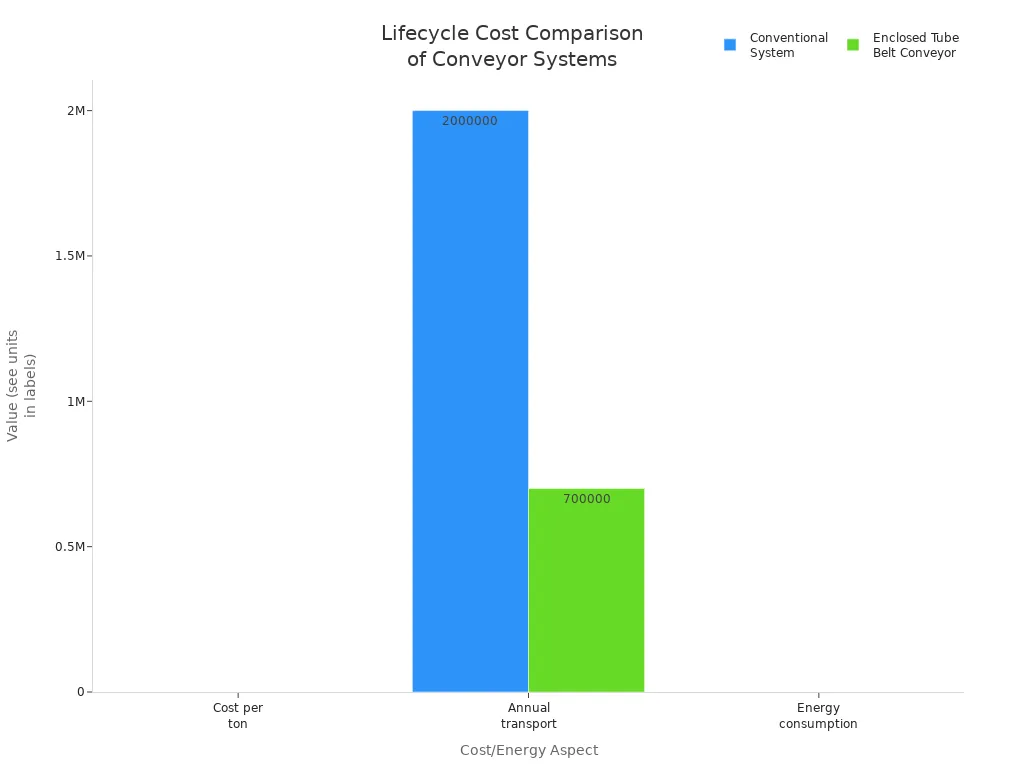

The chart shows tube belt conveyors use less energy than regular ones. You help the planet by making less pollution. You also spend less money each year.

Reduced Maintenance Needs

Tube belt conveyors are easier and cheaper to take care of. You do not have to clean up spills or fix dust problems a lot. The closed design keeps parts safe from rain and dirt. You spend less time and money fixing things.

Here are some easy ways to keep your tube belt conveyors working:

-

Check your system often to find problems early.

-

Watch the motor temperature so it does not get too hot.

-

Make sure pulleys are lined up to stop belt problems.

-

Keep pulleys clean so they last longer.

-

Use oil or grease when the maker says to stop friction.

You should also look for cuts or cracks on the belt. Fix carryback and tracking problems to waste less. Line up idlers often to use less energy.

Tip: Check your tube belt conveyors every day, week, and month. You will find problems early and keep things running well.

Tube belt conveyors help the planet by needing fewer repairs and making less waste. You save money and help the earth at the same time. Tubular conveyor technology gives you energy savings and helps you reach your green goals.

Enclosed tube belt conveyors work better and lower the risk of contamination. They move materials gently, so your product stays good. These systems save energy and cost less to fix. You make your workplace cleaner and safer, which helps the planet.

Industry Applications of Enclosed Environment Friendly Systems

Use in Regulated Sectors

Tube belt conveyors are used in many important industries. These places need to protect the environment and keep things clean. The systems help move materials safely. They stop dust, spills, and contamination from causing problems. You can use them where safety and cleanliness matter a lot.

Here is a table that shows where tube belt conveyors are used and why they help:

|

Industry |

Purpose of Use |

Environmental Benefit |

|---|---|---|

|

Mining |

Transporting ore over long distances while preventing dust escape |

Reduces environmental impact and improves safety |

|

Power Plants |

Moving coal, biomass, or other fuels while preventing dust and ash release |

Complies with environmental regulations |

|

Food Processing |

Transporting ingredients and finished products in sealed environments |

Prevents contamination and spoilage |

|

Chemical Handling |

Moving hazardous materials securely to prevent leaks and contain dust |

Ensures worker safety and environmental compliance |

You see tube belt conveyors in mining, power plants, and food factories. They are also used in chemical plants. These places want to keep workers and the earth safe. Tube belt conveyors are found in cement plants, farms, ports, and steel factories too. They help move things like minerals, coal, grains, chemicals, and waste. In sensitive areas, you need a system that keeps dust and spills inside.

Real-World Case Studies

Real examples show how these systems help. Many companies use tube belt conveyors to protect nature and keep people safe. Here are some ways these systems are helpful:

-

Pipe conveyors keep materials safe from rain, wind, and sun. You lose less product and help your company be greener.

-

The enclosed environment friendly system keeps materials safe and stops breakage. This is very important for coffee beans, which need to stay whole and fresh.

-

You can put bulk solids handling projects closer to towns. The system keeps the air clean and lowers pollution.

-

Stopping Material Spillage: The closed design stops leaks and keeps things clean.

-

Cutting Down Dust: The tube shape lowers dust, so the air is cleaner.

-

Saving Energy: Fewer transfer points mean you use less energy and make less pollution.

Tube belt conveyors help make workplaces safer and cities cleaner. They help you follow rules from groups like the FDA and USDA. These systems are very important where air pollution and contamination are big risks.

Note: Tube belt conveyors are best for moving fine or dusty materials. They help you reach green goals and protect people near your site.

You get lots of good things for the environment with enclosed tube belt conveyors. These systems stop spills and cut down on dust. They also use less energy and help you follow safety rules. The table below shows how these conveyors keep your materials safe and make fixing things easier:

|

Benefit |

Description |

|---|---|

|

Waterproof |

Keeps products dry and safe from bad weather. |

|

Contamination Prevention |

Separates goods from dirt and germs, important for sensitive items. |

|

Temperature Control |

Moves products at the right temperature, good for perishables. |

|

Reduced Maintenance |

Needs less upkeep because parts stay clean. |

You should think about using enclosed tube belt conveyors for your business. This is extra important if you work where there are strict environmental rules. These systems keep your materials safe from rain, dust, and harsh weather. They help you follow safety laws and keep your workplace neat.

Bulk material handling will get even better in the future. Companies are using smart technology and renewable energy to make things cleaner and safer. You will see more machines doing work by themselves and better ways to watch materials. Eco-friendly conveyors will help companies make less pollution and keep people safe.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported