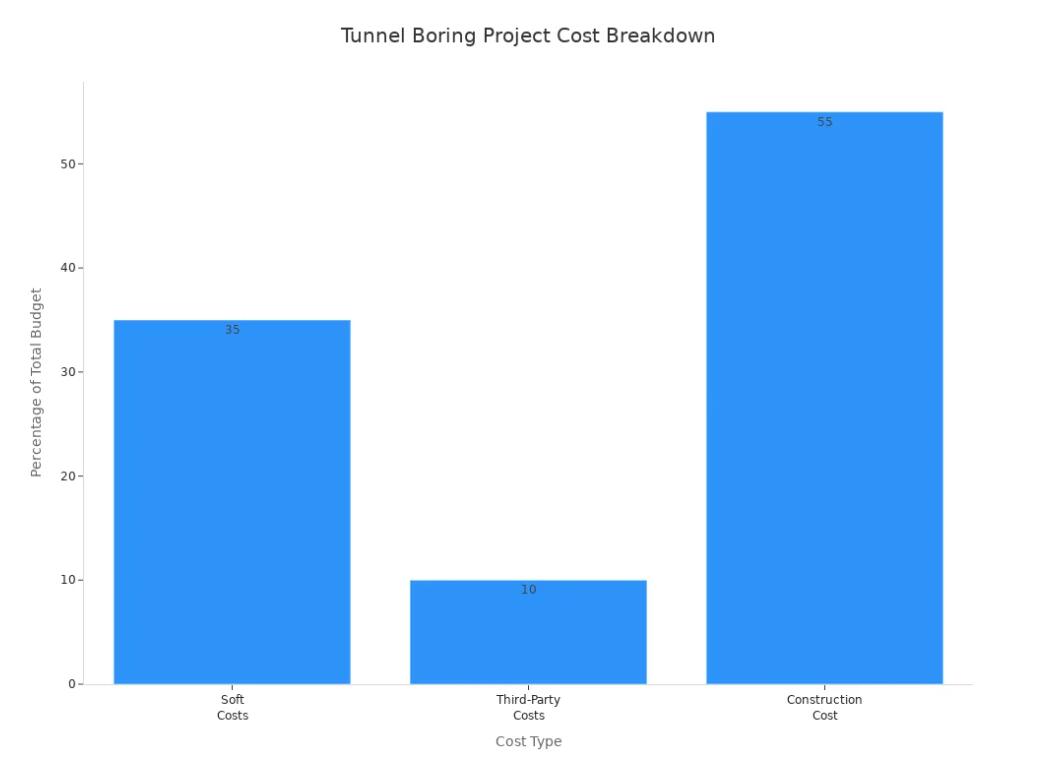

You have many costs to think about when you plan a tunnel boring project. The main costs are buying or renting a tunnel boring machine, paying workers, getting tunnel boring equipment, and soft costs like permits and insurance. Direct costs usually come from building work. Soft costs pay for project management and following rules. The table below shows how much each cost type adds to the total budget:

| Cost Type | Percentage of Total Budget |

|---|---|

| Soft Costs | 35% |

| Third-Party Costs | 10% |

| Construction Cost | 55% |

You also need to think about things like the type of ground and how deep the tunnel is. These things can change the costs. If you pick a dual mode tunnel boring machine from nhiglobalequip, you might keep costs lower in tough situations.

Tunnel Boring Machine Costs

Machine Acquisition or Rental

When you start a tunnel boring project, you have a big choice. You need to decide if you will buy or rent a tunnel boring machine. The price changes based on the size and who makes it. Here are some usual prices you might see:

- A tunnel boring machine in 2025 can cost from $10 million to $100 million.

- Most standard tunnel boring machines cost about $20 million.

- Smaller machines are cheaper, but bigger and advanced ones can cost over $100 million.

- For example, an 8-meter tunnel boring machine costs about $8 million. A 16-meter machine can cost $76 million or more.

If you rent a tunnel boring machine, you pay less at first. Renting means you do not need a big payment right away. But if your project takes a long time, renting can end up costing more than buying. The table below shows the main ways buying and renting are different:

| Aspect | Purchasing | Renting |

|---|---|---|

| Initial Costs | High upfront investment | Lower initial costs |

| Long-term Costs | Potentially lower total expenses | Cumulative payments may exceed purchase |

Tip: Always check the total costs for your project before you choose to buy or rent a tunnel boring machine.

Support Equipment

You need more than just the tunnel boring machine to finish your project. Support equipment helps the machine work well and keeps everyone safe. Some common support equipment includes:

- Conveyor belts move dirt and rocks out of the tunnel.

- Ventilation systems keep the air clean inside the tunnel.

- Power supply units run the tunnel boring machine and other tools.

- Safety gear like helmets and masks protect workers.

You should plan money for these things because they add to your total cost. Good support equipment can help you avoid problems and keep your team safe.

Transport & Assembly

Moving and putting together a tunnel boring machine is hard work. These machines are huge and very heavy. Moving them can cause traffic problems, especially in busy cities. For example, moving two tunnel boring machines for the Crossrail project in London needed a lot of planning. Each machine weighed 1,200 tonnes and was 140 meters long. The team had to think about cost, time, and safety.

You might need to choose if you move the tunnel boring machine all at once or build it at the site. Moving the whole machine is rare because it costs a lot and is risky. Most teams send the parts and put the machine together at the project site.

The cost of moving and building the machine depends on its size and where your project is. Big machines and far-away places make costs go up. Small projects or places with less money may have trouble paying for these steps. Big projects with more money can handle the high costs better.

Note: If you plan well for moving and building the machine, you can avoid extra costs and keep your project on track.

Engineering & Design

Feasibility Studies

Every tunnel project starts with a feasibility study. This study checks if your plan can work. It also helps you guess the cost. In cities, these studies cost more. There are more rules and people to think about. You also need more planning steps. In the countryside, there are fewer problems. So, the cost is lower.

Feasibility study costs are higher for city tunnel boring projects. This is because there are more rules and people to talk to. Rural projects do not have as many of these issues. The Hannover-Wurzburg high-speed railway shows this. When you add up all costs, city and country projects can cost about the same. This means city projects may not be as expensive as people think.

You should always save enough money for this study. A good study can help you avoid big problems later.

Detailed Design

After the study, you start the detailed design. This is when you make the full tunnel plans. You pick the size, shape, and path. You also plan how to use the tunnel boring machine and other tools.

Many things can change the cost here:

- How complex the infrastructure is

- The type of contracting system

- Technical details about tunnel size

Big or complex tunnels cost more to design. Simple tunnels cost less. You should work with experts to make sure your plans are safe and clear.

Project Management

Project management helps your tunnel project stay on track. You need people to plan and watch the work. They also fix problems. Good managers help you finish on time. They help you avoid extra costs. They also make sure you follow rules and keep workers safe.

Pick managers who know about tunnel projects. They understand the special needs of a tunnel boring machine. They can help you avoid mistakes. Good project management can save you money and time.

Labor & Training

Skilled Labor

You need skilled workers to use tunnel boring machines. These workers know how to use complex machines. They help keep the project safe. If there are not enough skilled workers, you can have problems. Labor costs go up when companies want the same workers. Projects can be delayed if you cannot find enough people. You may need to pay for more time and supplies. If you hire workers who are not experienced, mistakes can happen. This can cause more costs and problems. It is smart to plan for these risks early. Hiring skilled workers helps you avoid mistakes. It also keeps your project on time.

Training Programs

You must train your team before they use tunnel boring machines. Training teaches workers how to use equipment and follow safety rules. It also helps them solve problems. Training programs cost money, but they help stop accidents and delays.

| Cost Component | Estimated Cost Range |

|---|---|

| Typical Training Program | $4,000 - $20,000 |

| Tuition Fees | $5,000 - $15,000+ |

| Equipment Usage Charges | $50 - $200 per day |

| Additional Expenses | Several hundred to over a thousand dollars |

You might also pay for safety gear, testing, and travel. Training is a good investment. It keeps workers safe and helps the project go well.

Subcontractors

You often need subcontractors for special jobs like electrical work or concrete lining. Subcontractors bring their own teams and tools. They help finish the project faster and fill skill gaps. You should check if they have good experience and a safe record. Good subcontractors save time and money. Bad ones can cause delays or extra costs. Always add subcontractor costs to your budget. Keep clear communication to avoid problems.

Permits & Compliance

Tunnel boring projects need you to follow many rules. You also need special approvals. These steps add soft costs to your budget. You must plan for owner costs and preconstruction work. You also need to think about environmental studies and design. Management, permits, insurance, financing, and bonding are important too. Careful planning helps you avoid surprises. It keeps your project on track.

Environmental Permits

You must get environmental permits before digging starts. These permits show your project will not hurt nature or people. You may need to check air quality and water safety. You also need to study noise levels. City projects often need more permits than rural ones. If you skip these steps, you might get fines or delays. Good planning helps you finish faster. It also helps you avoid extra costs.

Tip: Start your environmental studies early. This helps you find problems before they get bigger.

Regulatory Fees

Regulatory fees are different in each country. Some places have strict rules and high costs. Other places have easier processes. For example:

- The Jakarta subway project costs about $266 million per kilometer.

- The Dhaka metro costs around $400 million per kilometer.

- These numbers show how consultants and financing change costs in different regions.

You must pay for licenses, inspections, and approvals. These fees can make your project cost more. Places with tough rules are more expensive. Smaller companies may have trouble paying these costs. You should check local laws before you start.

| Region | Type of Project | Cost per Kilometer | Main Cost Factors |

|---|---|---|---|

| Jakarta | Subway (Underground) | $266 million | Permits, consultants, financing |

| Dhaka | Metro (Elevated) | $400 million | Consultants, financing, regulations |

Insurance & Bonding

Insurance protects you from accidents and damage. Bonding shows you can finish the project and pay for mistakes. You need both to start work. These costs depend on your project size and location. Big projects need more coverage. If you skip insurance or bonding, you could lose money if something goes wrong.

Note: Check your insurance and bonding needs often. This helps you stay safe and follow all rules.

You must watch your costs and check your budget often. Good cost checks and regular reviews help you avoid problems. They help you finish your tunnel boring project successfully.

Indirect & Ongoing Costs

Tunnel boring projects have costs that do not show up right away. You need to plan for these extra expenses. These costs can change your budget if you do not watch them.

Maintenance & Repairs

You must keep your tunnel boring machine working well. Regular maintenance helps you stop breakdowns. If a machine stops, your project can slow down. Repairs can cost a lot, especially if you need special parts. You should save money for planned and surprise repairs. Good maintenance keeps your project safe and on time.

Utilities & Consumables

Your tunnel boring project uses lots of power and water. You also need fuel, lubricants, and other supplies. These are called consumables. You use them every day, so costs add up fast. If you do not plan for these, you might run out or spend too much. You should track what you use and find ways to save.

Tip: Buy consumables in bulk to save money and avoid delays.

Working Capital

You need working capital to pay for daily needs. This money covers wages, bills, and small purchases. If you run out, your project can face delays. You should check your cash often and keep extra money for emergencies.

Here is a table that shows some common indirect costs in tunnel boring projects:

| Indirect Costs | Description |

|---|---|

| Overhead Costs | General office expenses not tied to tunneling work |

| Spoil Disposal | Removing and getting rid of dug-up material |

| Cross Passages | Building access points between tunnel sections |

| Portal Construction | Making the entrances and exits of the tunnel |

| Supervision Costs | Paying for people who watch over the project |

| Land Purchase | Buying land for the project, which can change costs in different places |

You should check these costs often. Careful planning helps you avoid problems and keeps your project on track.

Cost Drivers & Optimization

Geology & Depth

You need to check the ground before digging starts. The kind of rock and how deep you dig change your costs. If the rock is weak or broken, you need thicker tunnel walls. Lots of water underground means you need pumps and waterproofing. Special things in the ground, like faults or soft soil, make work harder and cost more. The tunnel size matters too. Bigger tunnels need more stuff and stronger support.

Here is a table that shows how these things affect your budget:

| Factor | Impact on Cost |

|---|---|

| Geological Conditions | Weak rock needs thicker lining. More water means extra systems. Special features raise costs. |

| Construction Technology | Different methods have different costs. |

| Degree of Mechanization | Advanced machines cost more at first but can save money later. |

| Tunnel Cross-Section Size | Bigger tunnels use more materials and are harder to build. |

Tip: Always study the ground before picking your tunnel boring machine. This helps you avoid problems.

Tunnel Lining & Construction

How you build tunnel walls changes your costs. Weak rock needs thicker and stronger linings. Strong rock lets you use simpler and cheaper walls. You can choose shotcrete, cast-in-place concrete, or precast segments. Each choice costs different and has its own benefits. The way you build, like using a tunnel boring machine or blasting, also changes your budget. Moving materials to your site costs more if it is hard to reach. You must follow safety and environmental rules, which add to your costs.

| Factor | Description |

|---|---|

| Geological Conditions | Weak rock needs thicker lining. Strong rock allows cheaper construction. |

| Lining Type and Material | Shotcrete, cast-in-place, and precast segments have different costs and uses. |

| Construction Technology | Drill-and-blast and TBM methods have different equipment and labor needs. |

| Tunnel Cross-Section Size | Larger tunnels need more materials and are harder to build. |

| Material Transportation | Hard-to-reach sites cost more to supply. |

| Environmental and Safety | Following rules adds to your costs. |

Cost Reduction Strategies

You can save money by planning well and using new technology. Many companies use artificial intelligence to plan workers and machines. This helps you avoid delays and keeps work moving. AI helps you use equipment better and makes the site safer. If you manage supplies well, you avoid running out or having machines break.

Here are ways companies save money:

- Use AI to get the most from machines and cut downtime.

- Improve how workers and machines move to avoid delays.

- Schedule labor with AI to use time and people better.

- Use AI to make safety choices fast, so work does not slow down.

- Manage supplies and equipment to avoid delays from shortages.

The Boring Company uses smart ideas to lower costs:

- They keep tunnel diameters small, about 12 feet, to use less material.

- They use electric-only designs, so they do not need expensive air systems.

- Their custom tunnel boring machines work faster and cost less to run.

- They turn dug-up dirt into bricks, which they sell or use, saving money and reducing waste.

Note: If you plan well and use good technology, you can finish your tunnel project faster and spend less.

You should know all the costs in tunnel boring projects. Direct costs and soft costs both change your budget. Planning ahead helps you avoid problems. You can keep costs down by:

- Checking project progress every week with CPI and SPI

- Using computer models to stop machine delays and help with moving things

- Watching resources and changing plans when needed

- Looking at the site before you begin work

- Talking with contractors to make risks smaller

Tip: Check your project often and use resources wisely. This helps you finish your tunnel safely and without spending too much.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported