NHI heavy duty jaw crusher is widely used in metallurgy, mining, building materials, chemical industry, cement and other industries. Light in weight and large in output, it has various specifications, including cast welding structure, frame structure, spring loading and hydraulic adjustment.

⚙️ Description of Jaw Crushers

NHI heavy duty jaw crusher is one of the main equipment for coarse and medium crushing of ores or rocks. It has the advantages of simple structure, reliable performance, easy operation, convenient maintenance and safe use. Jaw crusher can be divided into PEF compound swing jaw crusher (single toggle jaw crusher) and PEJ simple swing jaw crusher (double toggle jaw crusher) according to its structural characteristics.

Dual-series versatility: PEJ (double toggle) for heavy-duty operations, PEF (single toggle) for compact efficiency.

Innovative structure: Non-welded frames eliminate stress cracks, while wear-resistant tooth plates extend service life by 40%.

Energy-saving design: Rolling bearings reduce friction loss, achieving 20% higher productivity than traditional models.

⚙️ Specifications of Jaw Crushers

Model: PEJ-900×1200~PEJ-1500×2100

PEF-400×600~PEF-1500×2100

Feeding Opening Size (mm×mm):400×600~1500×2100

⚙️ Benefits of Jaw Crushers

Replaceable components (e.g., jaw plates, bearings) reduce downtime by 30%.

Standardized modules enable quick customization for specific materials (hard rock, limestone, etc.).

Forged high-strength alloy steel frames resist fatigue under heavy loads, ensuring 99% operational stability.

Heat-treated eccentric shafts with balanced flywheels minimize vibration and noise.

Support fixed-base, mobile chassis, or integrated plant configurations.

Adapt to diverse terrains (mountainous mines, coastal plants) with anti-corrosion coatings.

Shock-absorbing Foundation

Design of floating shock absorption foundation. Strong practicality of the foundation and seamless replacement with the original foundation.

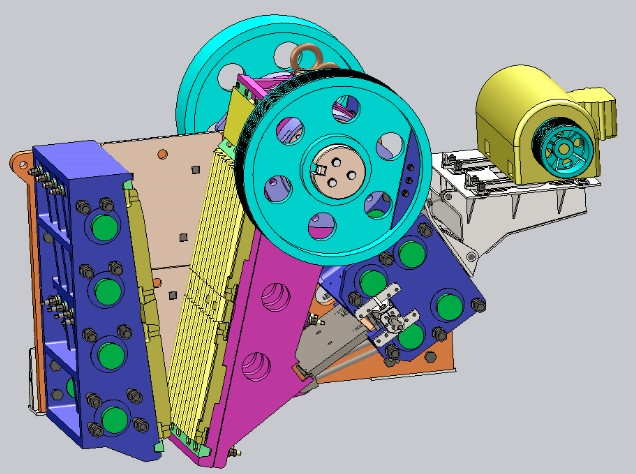

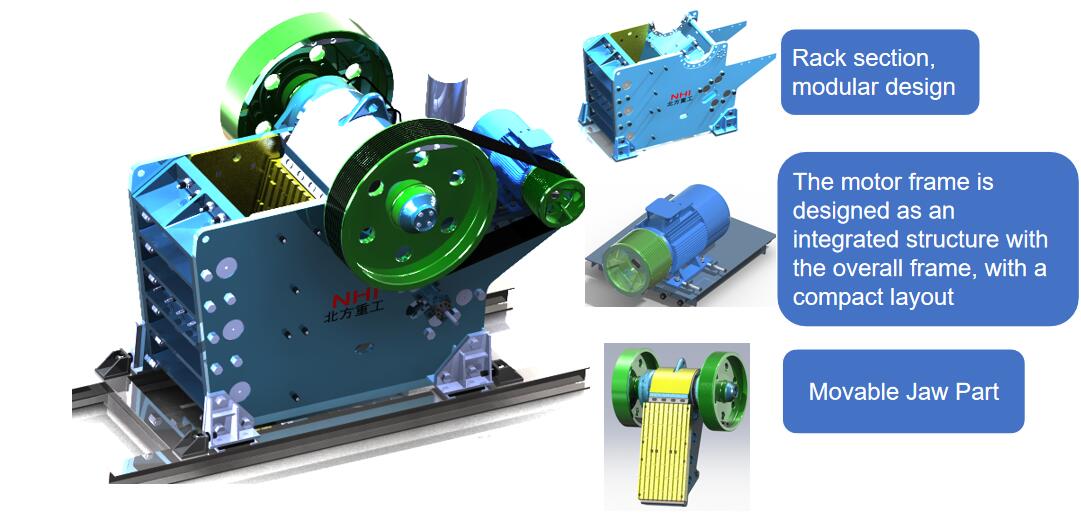

⚙️ Main Part of Jaw Crushers

⚙️ Global Project of Jaw Crushers

Domestic Cases:

Supplied 98 units to Benxi Jiali Mining for iron ore crushing, achieving 5Mt annual capacity.

Hebei Baoding Fengxiao project: PEF-1200×1500 models processed quartzite with <5% failure rate.

International Deployments:

39 limestone crushing lines in Brazil: PEJ-1300×1900 optimized for 95% particle uniformity.

Uzbekistan iron ore project: Dust-proof PEF models operated in -20°C~50°C environments with 40% lower maintenance costs.

Ghana Congo: 400t/h jaw crusher semi-mobile crushing station

⚙️ FAQ of Jaw Crushers

1. How do jaw crushers work?

heavy duty jaw crushers work by using two jaws—one fixed and one movable—to crush material. As the movable jaw moves back and forth, it compresses the material against the fixed jaw, breaking it into smaller pieces.

2. What is a jaw crusher used for?

A heavy duty jaw crusher is mainly used for primary crushing of hard materials like stone, ore, and concrete. It prepares raw materials for further processing in mining, construction, and recycling industries.

3. What is the jaw crusher system in the mines?

In mining operations, the jaw crusher system is typically used at the front end of the crushing process. It reduces large mined rocks into manageable sizes for secondary crushers or grinding mills.

⚙️ After-sales Service 400-600-4666 (24 Hour Online)

NHI's after-sales service center is equipped with a team of over 200 experienced engineers, who provide year-round services for various projects in China and overseas. They offer comprehensive on-site support, including son-site parts inspection, installation guidance, operation training, equipment commissioning, and performance testing for final acceptance. The team promptly provides technical support for any issues that arise during equipment operation and system, ensuring full-process service for users.

--------------占位---------------