NHI cone crusher is the main equipment used in metallurgical, mining, chemical, building materials, water and electricity, road construction and other industrial sectors to crush various ores or rocks of different hardness into middle or fine size.

Model:PYT0607~PYT2230

Cone bottom diameter (mm):600~2200

⚙️ Description of Cone Crushers

As setter of the cone crusher standard in China, NHI has designed and manufactured cone crushers for more than 50 years, and our cone crushers have four series and more than one hundred specifications. The cone crushers produced by us include PYT (spring cone crushers), PYY (single cylinder hydraulic cone crushers), PYS (Simmons cone crushers) and PYG (high-energy cone crushers), with more than 100 specifications. PYD series single cylinder hydraulic cone crusher is an efficient medium to fine crushing equipment developed by NHI.

⚙️ Specifications of Cone Crushers

* PYD series Single-Cylinder Cone Crusher

| Model | Install Power(kW) | Max Feed Point Size(mm) | Discharge Point Adjust range(mm) | Capacity (t/h) |

| PYD-132 | 132 | 185 | 6~38 | 43~208 |

| PYD-250 | 250 | 185 | 8~44 | 85~371 |

| PYD-315 | 315 | 275 | 13~51 | 167~652 |

| PYD-600 | 600 | 300 | 10~70 | 275~1422 |

* PYD-S series Single-cylinder Cone Crusher

| Model | Install Power(kW) | Max Feed Point Size(mm) | Discharge Point Adjust range(mm) | Capacity(t/h) |

| PYD-132S | 132 | 360 | 19~54 | 98~364 |

| PYD-250S | 250 | 450 | 32~54 | 247~521 |

| PYD-315S | 315 | 560 | 32~76 | 291~1030 |

*The output will vary according to different materials, feed particle size and other factors

⚙️ Benefits of Cone Crushers

High Efficiency & Large Crushing Ratio:

Adopts optimized crushing frequency and eccentricity to achieve rapid size reduction with minimal energy consumption.

Low Operating Cost:

Reduced wear on vulnerable parts and reliable oil lubrication system minimize maintenance and replacement expenses.

Superior Product Quality:

Laminated crushing technology ensures uniform, cubic-shaped finished products, ideal for high-demand construction and mining applications.

Advanced Hydraulic System:

Enables hydraulic protection against uncrushable materials and automatic cavity cleaning, reducing downtime and enhancing safety.

High Automation:

Intuitive controls and integrated monitoring systems simplify operation and maintenance, improving overall productivity.

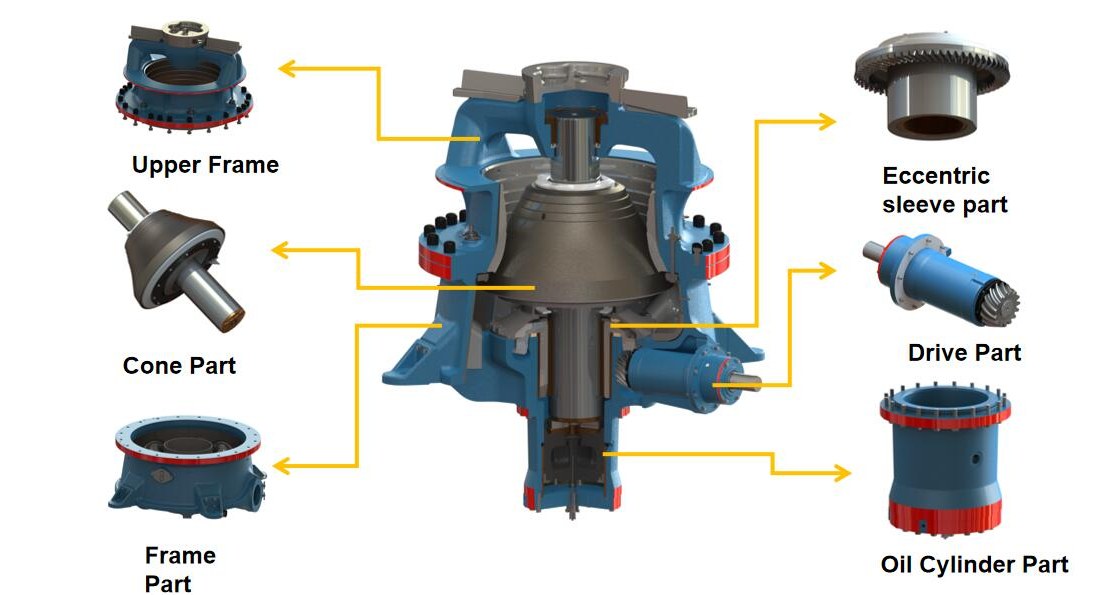

⚙️Structure of PYD Series Single-cylinder Cone Crusher

⚙️ Global Project of Cone Crushers

⚙️ FAQ of Cone Crushers

Q1: How does a cone crusher work?

A: Cone crushers crush material between a moving cone (mantle) and a fixed cone (concave). The motor drives the eccentric shaft, which causes the cone to rotate and compress material in the crushing chamber.

Q2: What are the advantages of a cone crusher over jaw crusher?

A: Cone crushers offer better crushing efficiency for secondary and tertiary crushing, deliver finer output size, have lower wear costs, and are better suited for abrasive materials compared to jaw crushers.

Q3: What types of cone crushers are there?

A: There are three main types: Spring Cone Crusher, Hydraulic Cone Crusher, and Compound Cone Crusher. Each type serves different capacity needs and crushing applications.

⚙️ After-sales Service 400-600-4666 (24 Hour Online)

NHI's after-sales service center is equipped with a team of over 200 experienced engineers, who provide year-round services for various projects in China and overseas. They offer comprehensive on-site support, including son-site parts inspection, installation guidance, operation training, equipment commissioning, and performance testing for final acceptance. The team promptly provides technical support for any issues that arise during equipment operation and system, ensuring full-process service for users.

--------------占位---------------