AG and SAG Mill are high-performance grinding equipment widely used in mineral processing, metallurgy, construction and chemical industries.

⚙️ Description of SAG Ball Mills

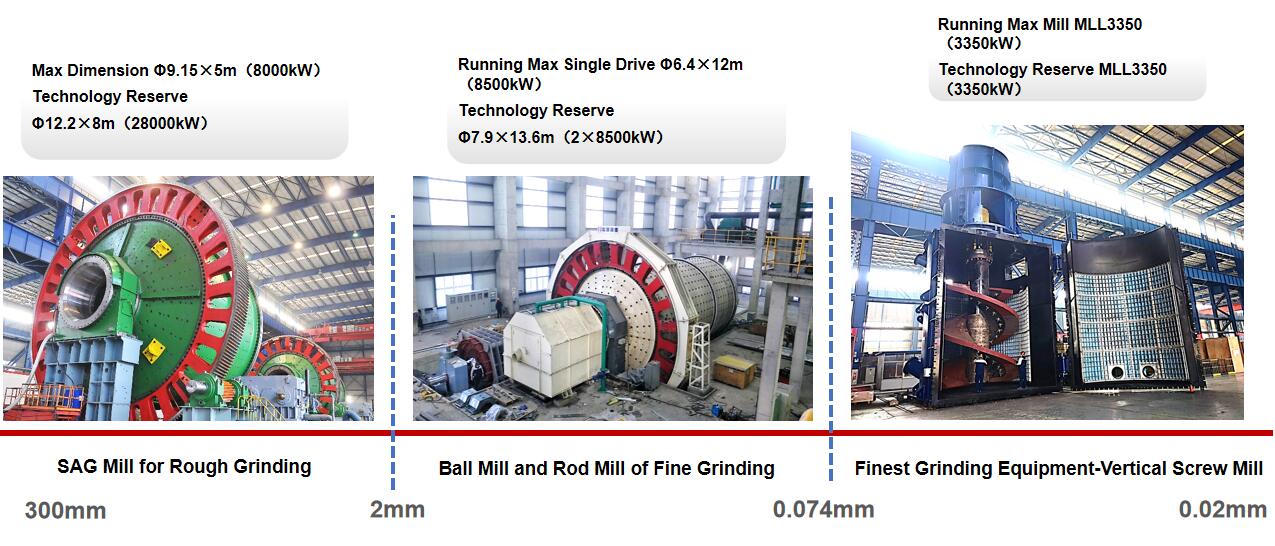

NHI autogenous (AG) and semi-autogenous (SAG) mills are powerful grinding equipment used in the primary stage of mineral processing. AG mills use only the ore itself as grinding media, while SAG mills add a small portion of grinding balls. NHI break the international technological monopoly and develop Φ large equipment such as 9.15m SAG mill has become the largest complete set of mine equipment supplier in China. In the international market, our products serve more than 30 countries and regions, and users are distributed in large mining enterprises, which can achieve rapid global response.

Our ball mills are engineered for rugged performance and integrated with advanced monitoring systems to ensure consistent operation, reduced wear, and extended service life.

⚙️ Specifications of SAG Ball Mills

Model:MQY0909~MQY79136

Drum Specification Parameter (Dia. mm×Length mm):900×900~7900×13600

⚙️ Benefits of SAG Ball Mills

Reduced Steel Consumption: AG mills eliminate steel ball usage, cutting wear costs by 30–50% compared to conventional ball mills.

High Processing Capacity: Large drums (up to 11000mm) enable throughput of 100–3000 tons/hour, ideal for large-scale mining projects.

Flexible Material Adaptability: Handles hard ores (e.g., granite, basalt) and sticky materials, with SAG mills suitable for mixed hardness feeds.

Energy Efficiency: Optimized drum rotation and material crushing reduce power consumption by 15–20% versus traditional grinding systems.

Low Maintenance: Fewer moving parts and reduced steel wear mean less frequent maintenance, extending service life to 8–10 years.

Integrated Automation: Optional PLC control systems enable real-time monitoring of grinding efficiency and remote operation.

⚙️Reference List of Ball Mills

⚙️ Global Project of SAG Ball Mills

Angola 2024. 1 set, Φ 6400 × 3750mm SAG mill Power: 2800kW

⚙️ FAQ of Autogenous and Semi-Autogenous Mill

1. What is the difference between autogenous and semi-autogenous mills?

Autogenous mills use the ore itself as grinding media. Semi-autogenous mills use both the ore and added grinding balls, improving efficiency and flexibility.

2. What materials can be processed in AG/SAG mills?

AG/SAG mills are ideal for hard and abrasive ores like iron ore, copper ore, gold ore, nickel ore, and other non-ferrous metals.

3. What are the advantages of AG/SAG mills?

They offer high capacity, reduced energy usage, simplified process design, and lower operational costs compared to traditional ball mills.

⚙️ After-sales Service 400-600-4666 (24 Hour Online)

NHI's after-sales service center is equipped with a team of over 200 experienced engineers, who provide year-round services for various projects in China and overseas. They offer comprehensive on-site support, including son-site parts inspection, installation guidance, operation training, equipment commissioning, and performance testing for final acceptance. The team promptly provides technical support for any issues that arise during equipment operation and system, ensuring full-process service for users.

--------------占位---------------