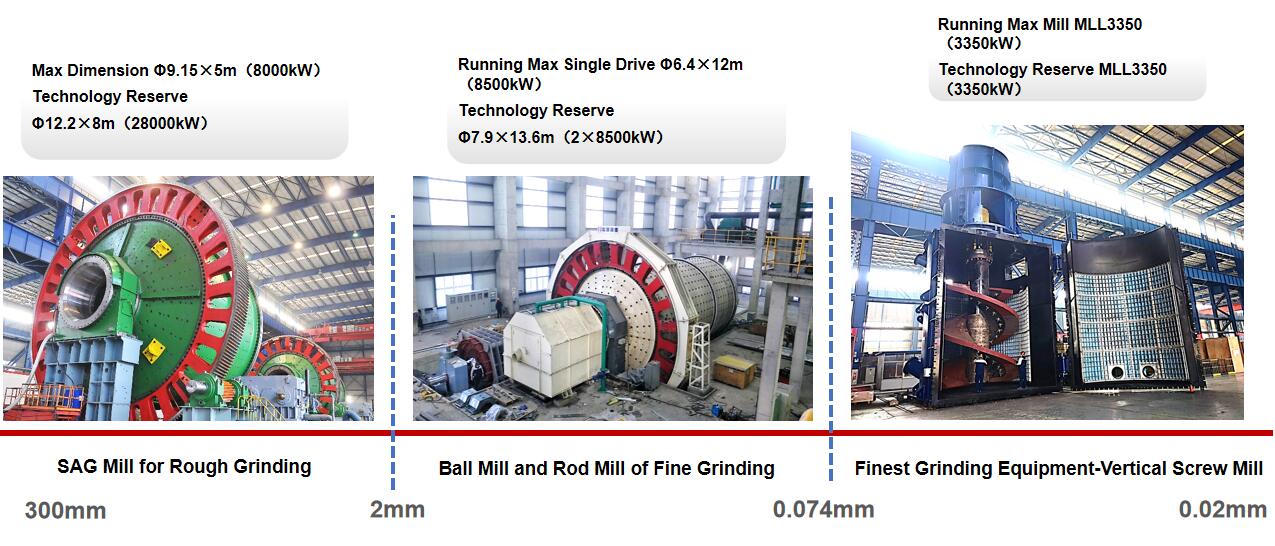

The spiral vertical mill is mainly used in the crushing and grinding of metal ores, the crushing and deep processing of non-metallic ores, the comprehensive utilization of low-grade minerals, the extraction of useful elements from tailings and other mining industries, powder metallurgy, mechanical alloying, metallurgical raw material treatment, utilization of metallurgical waste residue, cemented carbide production and other industries.

⚙️ Description of Spiral Vertical Mill

NHI vertical spiral mill is a new-generation fine grinding equipment, specifically designed for ultra-fine and high-efficiency grinding of mineral materials. It integrates advanced vertical structure with spiral motion of grinding media, enabling a high level of grinding precision with low energy consumption.

NHI has more than 10 years of development and manufacturing experience, with specifications including MLL355 to MLL4500 (4500kW). Customized research and development design can be tailored to specific needs. The only international company with both high-speed and low-speed successful performance.

Features:

Widely used in the fields of fine grinding and ultrafine grinding of metal and non-metallic minerals.

The maximum feed particle size is 6mm, and the minimum product particle size can reach 20 μ M

Thin and high structure, saving 50% of construction area.

Save 50% of steel consumption compared to conventional ball mills.

Save 35-50% of electricity compared to conventional ball mills.

⚙️ Specifications of Spiral Vertical Mill

Model:MLL200~MLL3357

Power (kW):200~3357

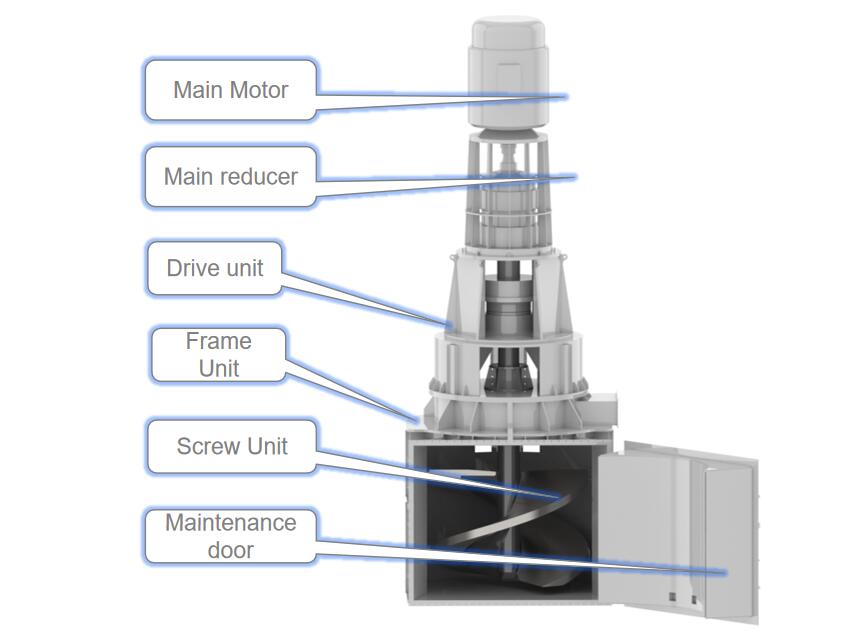

⚙️ Structure of Spiral Vertical Mill

Main Parts

Transmission part, frame part, screw part, access door, screw installation tool, foundation anchor bolt.

Out-bought Parts

Main Motor, main Gear box, main coupling.

⚙️Reference List of Ball Mills

⚙️ Global Project of Spiral Vertical Mill

Benxi Dong Fang San Jiazi Mining, MLL1200 Screw Vertical Mill, 7 sets

⚙️ After-sales Service 400-600-4666 (24 Hour Online)

NHI's after-sales service center is equipped with a team of over 200 experienced engineers, who provide year-round services for various projects in China and overseas. They offer comprehensive on-site support, including son-site parts inspection, installation guidance, operation training, equipment commissioning, and performance testing for final acceptance. The team promptly provides technical support for any issues that arise during equipment operation and system, ensuring full-process service for users.

--------------占位---------------