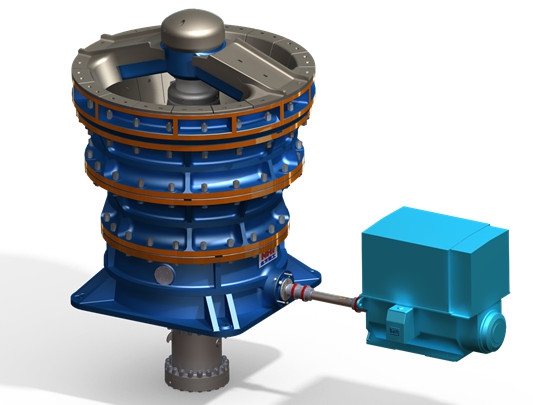

NHI High-efficiency Gyratory Crusher is one of the main equipment used for coarse crushing of ores or rocks, which is widely used in metallurgy, mining, building materials, chemical industry, cement and other industries.

Model: PXZ0913~PXZ1417

PXF4265~PXF60110

Feeding Opening Size (mm): 900~1524

Diameter of Moving Cone Bottom(mm): 1651~2794

⚙️ Description of Gyratory Crushers

NHI gyratory crusher is a heavy-duty crushing equipment designed for primary crushing of hard rock and ore materials. Our company is a professional manufacturer that designs, tests and manufactures gyratory crushers. It has a history of more than 60 years of designing and manufacturing gyratory crushers. Our high-efficiency gyratory crushers are complete in specifications, advanced in design, reliable in performance, stable in operation, low in energy consumption, large in crushing ratio and uniform in product size, and are well received by users at home and abroad.

There are PXZ (heavy type), PXQ (light type) and PXF (imported type) series of NHI rotary crushers, among which PXZ series rotary crusher is used to crush various materials with medium or higher hardness. PXQ series rotary crusher is used to crush various materials with medium or lower hardness; PXF series rotary crusher is used in large mines and ore dressing plant.

⚙️ Specifications of Gyratory Crushers

*Imported Upgraded PXF series Gyratory Crusher

|

Model |

Main Motor |

Feeding Point Size(mm) |

Discharge Point Size(mm) |

Max Feeding size(mm) |

Capacity( t/h) |

|

|

Power(kW) |

Rotary Speed(r/min) |

|||||

|

PXF 4265 |

450 |

600 |

1065(42″) |

145 |

900 |

1500~2150 |

|

PXF 5065 |

450 |

600 |

1270(50″) |

150 |

1100 |

1650~2500 |

|

PXF 5475 |

500 |

500 |

1372(54″) |

170 |

1150 |

2500~3300 |

|

PXF 6089 |

630 |

500 |

1524(60″) |

180 |

1300 |

3500~5000 |

|

PXF 60110 |

1000 |

500 |

1524(60″) |

190 |

1300 |

5800~7000 |

*The output will vary according to different materials, feed particle size and other factors

⚙️ Benefits of Gyratory Crushers

Advanced Hydraulic Adjustment System

The hydraulic tramp release mechanism instantly clears foreign objects, preventing damage and reducing downtime.

Automatic setting adjustment ensures consistent product size, adapting to varying material hardness in real-time.

High-Precision Gear Transmission

Precision-cut spiral bevel gears and a heavy-duty eccentric shaft provide smooth, low-noise operation with minimal maintenance requirements.

The integrated lubrication system extends gear life by up to 40% through continuous, optimized oil circulation.

Customizable Installation Options

Available in fixed-base and mobile configurations, our gyratory crushers can be tailored to diverse project requirements, from open-pit mines to urban construction sites.

Modular design allows for quick assembly and disassembly, reducing installation time by 20%.

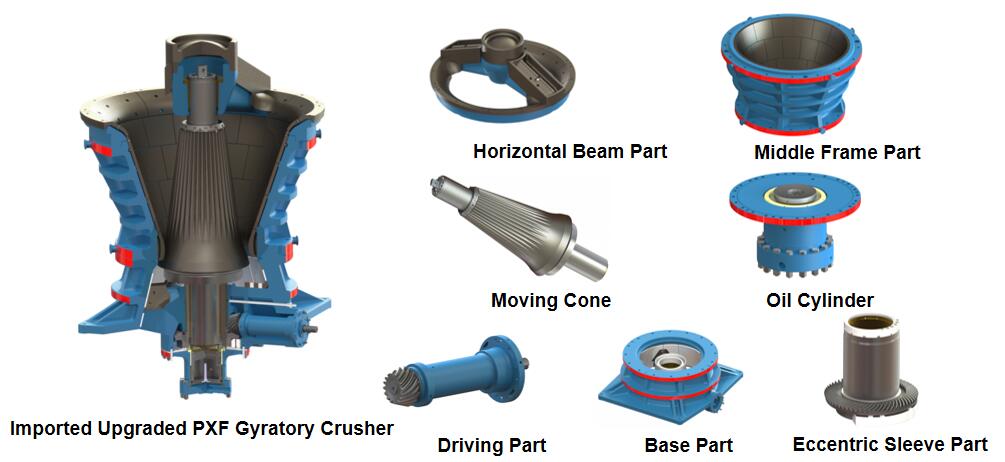

⚙️Structure of the Imported Upgraded PXF Series Gyratory Crushers

⚙️ Global Project of Gyratory Crushers

Supplied 32 GY Series crushers to Inner Mongolia iron ore mines, boosting annual production capacity by 12 million tons while reducing operational costs by 15%.

Collaborated with Shandong cement plants, where GYS crushers processed limestone with a 98% reliability rate over 5 years of continuous operation.

Delivered 18 mobile gyratory crushers to Australian gold mines, enabling on-site crushing and reducing transportation costs by 30%.

In Chilean copper mines, our customized GY-2000 models achieved a crushing ratio of 8:1, setting a new industry standard for efficiency.

⚙️Semi-moving Gyratory Crusher Station

The technology of NHI Gyratory Crushing Station originates from the Germany Thyssen Krupp semi mobile crushing station technology, which has the advantages of robustness, stability, safety, efficiency, and reasonable layout.

West Australia SINO Ore: :6389 Semi-Moving Crushing Station.

⚙️ FAQ of Gyratory Crushers

Q1:How Does A gyratory crusher Work?

A: A gyratory crusher works by using a conical crushing chamber. The eccentric shaft makes the movable cone oscillate within the fixed cone, squeezing and crushing materials fed from the top. As the materials break, they fall through the narrowing gap to become smaller-sized products.

Q2: What is the difference between a gyratory crusher and a jaw crusher?

A: Gyratory crushers feature a conical crushing chamber and continuous, circular motion, ideal for high-volume, primary crushing of hard materials. Jaw crushers use a toggle - driven, reciprocating motion and are better for smaller - scale operations or secondary crushing.

Q3: How long is the typical service life of your gyratory crusher?

A: With regular maintenance, our gyratory crushers can operate effectively for over 50 years.

Q4: Is your gyratory crusher customizable?

A: Yes, we offer tailored designs to meet different site and material requirements.

⚙️ After-sales Service 400-600-4666 (24 Hour Online)

NHI's after-sales service center is equipped with a team of over 200 experienced engineers, who provide year-round services for various projects in China and overseas. They offer comprehensive on-site support, including son-site parts inspection, installation guidance, operation training, equipment commissioning, and performance testing for final acceptance. The team promptly provides technical support for any issues that arise during equipment operation and system, ensuring full-process service for users.

--------------占位---------------