Large ball mill is a high-performance grinding equipment widely used in mining, cement, metallurgy, power generation, and chemical industries. High crushing efficiency.

⚙️ Description of Ball Mills

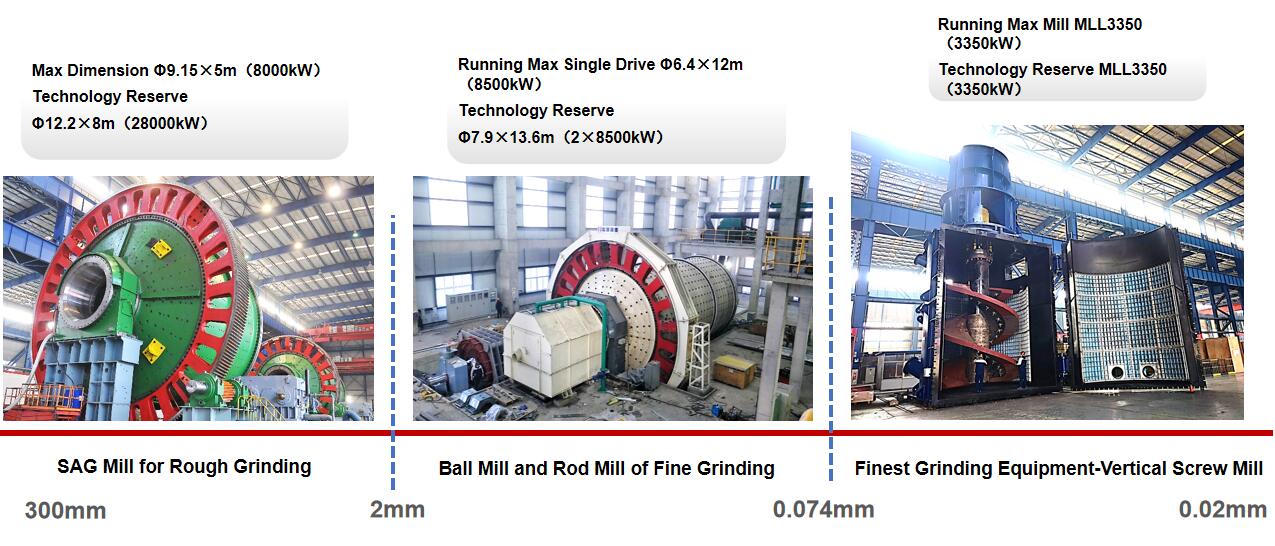

NHI began to produce mills since 1950s, especially in 1980s. Taking the opportunity of national reform and opening up, our company began to cooperate with foreign famous mill manufacturers such as A-C, Foster Wheeler, FLSmidth, MPSI and France's Stene ALSTOM to produce and introduce technology, digest and absorb the advanced technology of foreign mills, and combine our technical advantages, On the basis of the original innovation, gradually produce a large diameter and large size mill with independent intellectual property rights.

The ball mill has the advantages of high crushing ratio, good reliability, strong adaptability and large processing capacity. Our ball mill can be divided into dry type ball mill and wet type ball mill according to the grinding mode. According to the different ways of ore discharge, it can be divided into cell type and overflow type.

⚙️ Specifications of Ball Mills

Model:MQY0909~MQY79136

Drum Specification Parameter (Dia. mm×Length mm):900×900~7900×13600

⚙️ Benefits of Ball Mills

High Crushing Ratio: Achieves fine grinding with a single pass, ideal for processing hard and abrasive materials.

Strong Adaptability: Available in dry/wet grinding modes and cell/overflow discharge types to suit diverse process requirements.

Large Processing Capacity: Large-diameter drums (up to 7900mm) enable high-throughput production for large-scale industrial projects.

Reliable Performance: Decades of technical collaboration with global manufacturers ensure stable operation and low failure rates.

Flexible Configuration: Customizable designs based on material properties, output fineness, and production capacity needs.

Energy-Efficient Design: Optimized drum rotation and grinding media distribution reduce power consumption by 10–15% compared to traditional models.

⚙️Reference List of Ball Mills

⚙️ Global Project of Ball Mills

⚙️ FAQ of Ball Mills

Q1: How to select the right ball mill type for my material?

A: Choose dry/wet type based on material moisture content and cell/overflow discharge based on required output fineness. Our team can provide technical support for customized solutions.

Q2: What is the typical maintenance interval for a ball mill?

A: Routine inspections (lubrication, gear wear check) are recommended every 200–300 operating hours, with major overhauls every 8–12 months.

Q3: Can wet ball mills handle sticky materials?

A: Yes, wet grinding is suitable for sticky or high-moisture materials, as water helps prevent clogging and improves grinding efficiency.

⚙️ After-sales Service 400-600-4666 (24 Hour Online)

NHI's after-sales service center is equipped with a team of over 200 experienced engineers, who provide year-round services for various projects in China and overseas. They offer comprehensive on-site support, including son-site parts inspection, installation guidance, operation training, equipment commissioning, and performance testing for final acceptance. The team promptly provides technical support for any issues that arise during equipment operation and system, ensuring full-process service for users.

--------------占位---------------