You can see big changes coming to Tunnel Boring Machine technology. Industry leaders are looking at some new trends:

- Automation systems and real-time monitoring help make digging safer and more exact.

- AI-driven machines work better and lower mistakes made by people.

- Sustainability is important in new designs and how they work.

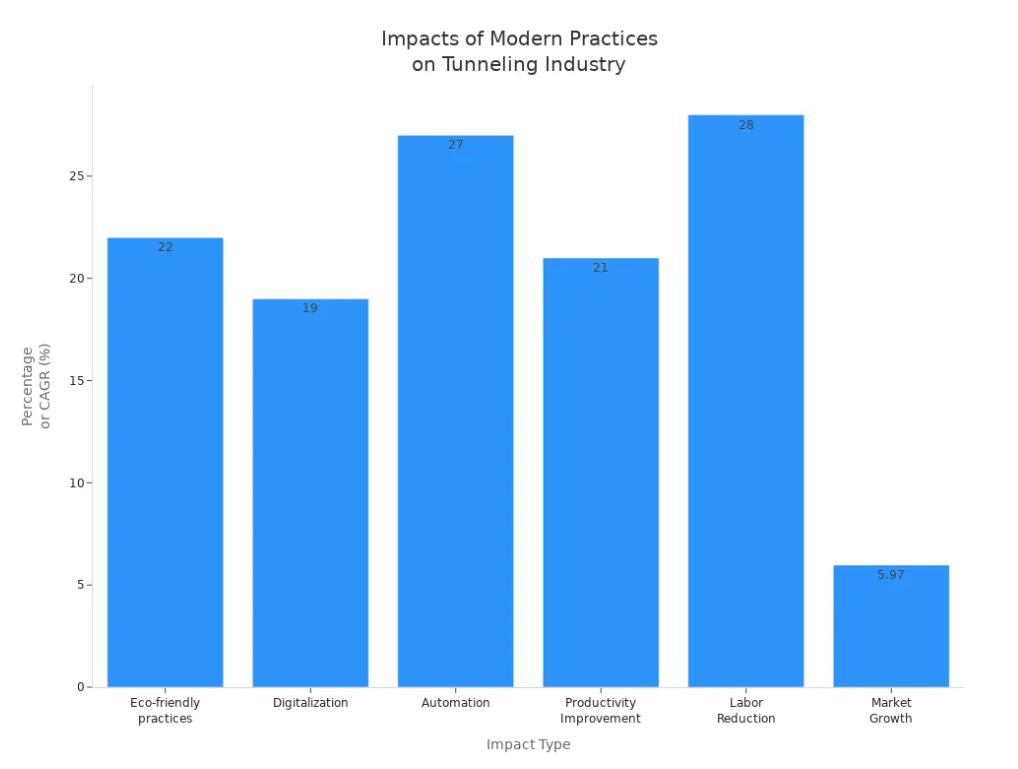

These changes help tunnel projects go faster, use less energy, and get more done. Recent data shows eco-friendly ways are used in 22% of new tunnels. Digital tools help finish building 19% faster. Automation means 28% fewer workers are needed and work goes up by 21%. The market is growing fast, with a predicted CAGR of 5.97% by 2033.

Digital Transformation in Tunnel Boring Machine

Digital transformation is changing how tunnel boring equipment works. Now, machines have more sensors and smart systems. Data tools are used in every Tunnel Boring Machine. These upgrades help you dig tunnels faster and safer. They also lower risks for workers.

IIoT and Real-Time Data

Tunnel boring equipment can connect to the Industrial Internet of Things (IIoT). Sensors watch things like pressure and strain while the machine works. The data goes to control systems right away. You always know what is happening underground.

Tip: Real-time data lets you spot problems early. You can change drilling speed or pressure quickly.

Here is a table that shows how IIoT helps you work better:

| Aspect | Description |

|---|---|

| Technology Integration | Automation, AI, IIoT, and data analytics are used in TBM operations. |

| Efficiency Enhancement | Drilling is optimized in real-time based on ground conditions. |

| Predictive Maintenance | Downtime is reduced by fixing things before they break. |

| Autonomous Operation | Machines are getting closer to working on their own. |

You can use a digital twin model. This is a computer copy of your Tunnel Boring Machine. Sensors send real data to the model. You can watch and control the machine from anywhere. Deep learning tools help you guess how the machine will perform. You can change settings for better results.

AI and Predictive Maintenance

Artificial intelligence (AI) is now used in tunnel boring equipment. AI looks at data from sensors and predicts problems. This helps you fix issues before work stops.

- Machine learning tools, like Gradient Boosting Machines and Deep Q-Networks, help predict how well your Tunnel Boring Machine will work.

- AI also helps you see how your work affects the environment. It finds ways to lower risks.

Here are some real-world examples:

| Project Name | Description | Key Findings |

|---|---|---|

| Southwark Tunnel | Machine sensor data checked tunneling performance and machine behavior. | Neural networks captured performance and behavior well. |

| North Bristol Relief Sewer | Neural networks and ground data predicted tunneling progress before work started. | Tunnel completion was predicted and spikes in digging speed were found. |

Predictive maintenance saves money and time. Repairs can be planned when the machine is not working. This means you do not lose time or money. Equipment lasts longer and workers stay safe.

Automation and Control

Automation makes tunnel boring equipment smarter. Systems can install tunnel segments and remove dirt with little help. This makes work faster and safer.

Here are some new features you might see:

| Advancement Type | Description |

|---|---|

| Improved Navigation Through Machine Learning | A laser-based system shows where the machine is. Survey tools do not need to move often. This saves time and needs fewer workers. |

| Fully Automated Subsystems | Machines install tunnel parts and clear dirt on their own. This is very helpful in long tunnels. |

| Enhanced Data Management Systems | Data can be seen and used in real-time. This helps you manage projects better and keep track of everything. |

Note: Companies like nhiglobalequip add smart features to tunnel boring equipment. They help you use digital tools and automation for better results.

There are challenges with new digital tools. You need to spend money on new systems and train your team. Sometimes, old and new systems are hard to mix. But you get big chances to improve safety, speed, and save money. Automated systems and digital models help you work faster and keep workers safe. Remote robots can do repairs, so people do not go into risky places.

Digital transformation is not just a trend. It is now a key part of every Tunnel Boring Machine project. You get more control, better safety, and higher profits with these new tools.

Eco-Friendly and Sustainable TBM Solutions

More tunnel boring equipment uses eco-friendly systems now. These changes help save energy and protect the soil. They also lower emissions. Projects become safer for people and the planet.

Energy Efficiency

New energy-saving features help Tunnel Boring Machines use less power. This also helps cut costs.

- You can set a shutdown rule for the slurry circuit. This happens during ring building. It helps reduce energy use.

- Machines can change to fit different ground types. This saves energy.

- Some tunnels use solar panels for monitoring systems. The Gotthard Base Tunnel does this.

- Water recycling systems help use less local water.

- Refurbishing machine parts cuts greenhouse gas emissions by 65%. It also lowers electricity use by 80%. Material waste drops by 99%.

- LED lighting replaces old halogen lamps. This lowers energy needs.

Tip: Pick machines with these features. Your project will be greener and cheaper.

Minimizing Soil Disturbance

You want to keep the ground safe and stable. New materials and methods help with this.

| Material/Method | Description |

|---|---|

| Eco-conscious foaming agents | Biodegradable products lower the impact of soil you dig up. |

| Polymers | Help control the ground and work better in tough conditions. |

| Hard rock TBM solutions | Reduce tool wear, control dust, and move soil more safely. |

Tunnel boring equipment can dig with less vibration and ground movement. This makes work safer in cities. Controlled digging creates less dust, noise, and debris. You can bore through many types of ground. You can also install tunnel walls at the same time.

Emission Reduction

You can lower emissions by using rebuilt machines. These machines work on many projects. You do not need to build new ones each time. Onsite First Time Assembly lets you put machines together at the site. This saves time and cuts carbon from shipping. Mechanically dug tunnels have smoother walls. They need less support. You remove less soil and create fewer emissions.

Note: You help the environment when you choose these methods for your tunnel boring equipment.

There are some barriers to using green practices. High costs, strict rules, tough ground, and not enough skilled workers can slow you down.

| Barrier Type | Description |

|---|---|

| High Upfront and Operational Costs | You need a lot of money to buy and set up new machines. Smaller companies may struggle with this. |

| Regulatory Compliance | You must follow many rules about safety and the environment. This can delay your project and raise costs. |

| Geological Challenges | Hard-to-predict ground can damage machines and make work harder. |

| Shortage of Skilled Labor | Not enough trained workers means higher costs and slower progress. |

You can overcome these barriers by planning ahead and training your team. Using sustainable tunnel boring equipment helps the planet and your business.

Advanced Tunnel Boring Machine Design

Variable Diameter and Modular TBMs

Some tunnel boring equipment can change size while working. The first diameter-adjustable Tunnel Boring Machine lets you change tunnel size as you dig. You start small and make the tunnel bigger at stations. This way, you do not need to take the machine apart. You also do not need to build extra shafts. This saves time and money.

Variable Density TBMs use smart designs to stop clogging. They keep materials moving in tough ground. These machines switch how they work to match the soil. You get more choices and better results.

Micro and adaptive tunneling helps in busy cities. You disturb less ground and adjust to different soils. You finish projects faster and avoid delays.

Tip: Pick modular tunnel boring equipment for changing projects. You can add or remove parts to fit tunnel sizes.

Autonomous Operation

Tunnel boring equipment can now work with little help. Autonomous Tunnel Boring Machine systems use sensors and smart controls. You set the path and the machine digs. The system checks the ground and changes speed or pressure.

Robotic technology helps install tunnel segments and remove dirt. Robots do risky jobs and keep workers safe. You finish tunnels faster and spend less money.

Some machines use digital twins. You watch and control the Tunnel Boring Machine on a computer. You see real-time data and make changes without stopping work.

Note: Autonomous operation means fewer workers underground. Tunneling is safer and more efficient.

Adaptive and Continuous Excavation

New methods let you dig tunnels without stopping. Continuous tunneling technology installs lining segments while digging. You work 1.6 times faster than older ways.

Plasma micro TBMs use plasma torches to cut hard rock. You dig faster and use less energy in tough ground. Variable density TBMs work under different pressures. You do not need big changes for soft or hard soils.

Here is a table that shows how these technologies help:

| Technology Type | Benefits |

|---|---|

| Continuous tunneling technology | Lets you work 1.6 times faster by not stopping for lining segments. |

| Plasma micro TBM | Digs faster in hard rock using plasma torches. |

| Robotic technology | Speeds up TBM and SCL work, lowers costs, and increases tunnel demand. |

| Variable density TBMs | Gives better control in soft soils and fits many ground types. |

| Variable density TBMs | Works under different pressures without big changes, making it more flexible. |

You see these new Tunnel Boring Machine designs in pilot projects. The Hawthorne Test Tunnel used advanced TBM technology. The team finished a 1.14-mile tunnel ten times faster than old machines. The LVCC Loop project built a 1.7-mile system in one year for $47 million. This is much cheaper than subway projects.

Implementation Challenges

There are some problems with advanced tunnel boring equipment:

- Plasma generation uses a lot of energy and costs more.

- You need a big investment and special training for new technology.

- Handling melted and vaporized rock needs careful planning.

- Not much field testing means you must wait for more proof before using these methods everywhere.

Alert: Plan for extra costs and training with advanced Tunnel Boring Machine designs. Test new methods before using them on big projects.

The future of tunnel boring equipment is in these new designs. You get more choices, safety, and speed. You help build tunnels for changing needs and tough ground.

Market Trends and Regulatory Shifts

Global Digitization Impact

All over the world, digital tools are changing the tunnel boring machine market each year. Companies use AI, automation, and real-time data to make tunnel boring equipment safer and better. In Asia-Pacific, cities are getting bigger very quickly. More people and new buildings mean there is a need for better tunneling solutions. China and India are leading this growth with many metro and highway projects. North America is also spending money on new infrastructure, so more modern tunnel boring machines are used.

- Asia-Pacific is growing the fastest because cities are getting bigger.

- China and India need more tunnel boring equipment for large city projects.

- Governments spend money on transport, which increases demand.

Tip: If your city is growing, you will probably see more digital tunnel boring equipment on your job sites.

Infrastructure Investment

More cities are putting money into underground systems to help with traffic and update utilities. Automation and real-time monitoring in tunnel boring machines help you dig more safely and exactly. The machines can be expensive, but new money helps pay for them.

- In March 2024, India gave more money to metro projects in cities like Lucknow and Pune.

- The European Investment Bank gave €500 million for green tunnel projects.

- As cities grow, there is more need for smaller, better tunnel boring equipment.

| Region | Recent Investment Example |

|---|---|

| India | Metro funding boost in 2024 |

| Europe | €500 million loan for tunnel projects |

Evolving Standards

You have to follow stricter safety and environmental rules when you use tunnel boring equipment. New rules make you use machines that create less pollution and keep workers safe. Automated tunnel boring machines help you meet these rules by lowering risks and helping the environment. Companies now use ISO 9001 and ISO 14001 to stay ahead and work in new places.

- More people in cities and new rules mean there is a need for eco-friendly tunnel boring machines.

- Real-time monitoring and AI make work safer and faster.

- Working with other countries helps you share technology and grow your business.

Note: If you work with partners from other countries, you can get the newest tunnel boring equipment and follow new rules.

Advanced Backfilling and Support Systems

Integration with TBM Operations

You can see new backfilling systems working with tunnel boring equipment on today’s projects. These systems mix and pump grout to fill spaces around tunnel parts. They use special materials like lightweight cellular concrete. This stops heavy pressure on the soil and fills all gaps. Machines put in grout during each build step. This means there are no empty spaces and work goes quickly.

Tip: Using machines to inject grout keeps tunnels safe and helps stop the ground from sinking.

Fast trains need strong backfilling to handle shaking from the tracks. Lightweight cellular concrete lets the tunnel move a bit without breaking. This keeps the tunnel safe for a long time.

| Component | Benefit |

|---|---|

| Grout Mixing Systems | Makes good material for digging |

| Precision Pumping Equipment | Sends grout fast, so there is less waiting |

| Automated Control Systems | Helps you watch and control the work better |

Modern tunnel boring equipment uses sensors to check ground movement. You lock tunnel walls in place with the right grout mix. The mix has water, cement, and other special stuff. This keeps the tunnel strong and dry.

Immediate Tunnel Segment Support

You make tunnels safer and faster by adding support right after digging. Early supports protect workers and machines. Permanent supports keep the tunnel strong for a long time. New grouting methods fill loose dirt and close gaps. This makes the tunnel stronger and stops leaks.

- Putting in supports early keeps your team safe while digging.

- Permanent supports help the tunnel last many years.

- New grouting makes the ground steady and blocks water.

AI and robots now help check sensor data and find problems. Robots can do risky jobs, so your team is safer. In Japan, rectangular tunnel boring machines kept the ground from sinking more than 13.1 mm. This is much less than the 30 mm limit. Most tunnels stayed under 10 mm, even in sandy dirt. You can see how good design and strong fillers stop sinking and make tunnels safer.

Note: Adding support right away and using new backfilling methods makes your Tunnel Boring Machine projects safer and faster.

Tunnel boring equipment is changing quickly. New things like AI, digital twins, and swarm robotics help make tunnel boring machines safer and smarter. Using digital tools and green designs helps tunnels last longer. These changes also protect the environment. Experts think the market will grow a lot. Cities need better underground systems.

When you use advanced tunnel boring machines, you make work safer and faster. You also get more done. Try these new ideas to be a leader in building tunnels.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported