Picking the right jaw crusher for rock helps you save money. It also makes your work better. You need to think about things like how hard the material is. You should check if the rock is rough or smooth. The size of the pieces you put in matters too. These things change how well your mining equipment works. Choosing good rock crushing equipment affects:

-

How much energy you use and how much it costs

-

How often you need new wear parts

-

How much fixing and care your machine needs

NHI has choices like a heavy duty jaw crusher for different jobs.

Jaw Crusher Overview

What Is a Jaw Crusher

A jaw crusher breaks big rocks into smaller pieces. It uses two plates to crush the rocks. One plate does not move. The other plate moves back and forth. You put big rocks in at the top. Smaller pieces come out at the bottom. Jaw crushers are used at mining and building sites. They can crush hard rocks like granite, basalt, and limestone.

Here are some common types of jaw crushers:

|

Type of Jaw Crusher |

Description |

|---|---|

|

Blake (Double Toggle) |

Standard for primary and secondary crushing of hard, tough abrasive rocks; produces a coarse product. |

|

Overhead Pivot (Double Toggle) |

Allows higher speeds and capacities; more energy efficient. |

|

Overhead Eccentric (Single Toggle) |

Encourages feed and discharge; higher speeds but more wear; cheaper and space-efficient. |

|

Dodge |

Provides a closer sized product; difficult to build large sizes; prone to choking. |

A heavy duty jaw crusher is good for hard rocks. It also works well for big jobs. This type gives strong power and lasts a long time.

Role in Rock Processing

People use jaw crushers for many rock jobs. The main jobs are:

-

Breaking big rocks for building projects

-

Getting minerals from ore to get metals

-

Recycling things like glass or rubber

-

Crushing rock samples for science

You can use a jaw crusher for granite, basalt, and limestone. This machine helps you get rocks the right size and shape. Picking the right crusher saves you time and work.

Jaw Crusher Types

When you look at the types of jaw crushers, you see that each one fits a different job. You need to know which jaw crusher works best for your rock processing needs. NHI offers a range of jaw crushers, including heavy duty jaw crusher models for tough jobs.

Single Toggle Jaw Crushers

Single toggle jaw crushers use one moving jaw and one fixed jaw. The moving jaw swings up and down. This design gives you higher throughput and makes maintenance easier. You find fewer shafts and bearings in this type, so you spend less time fixing it. Single toggle jaw crushers work well for softer materials and give you fast size reduction.

Tip: Choose a single toggle jaw crusher if you want simple maintenance and high output for less abrasive rocks.

Double Toggle Jaw Crushers

Double toggle jaw crushers have two toggles and more moving parts. The extra parts make these jaw crushers heavier and stronger. You use them for hard, abrasive materials. The motion is different, so you get a steady crushing force. Maintenance takes more time because of the extra parts, but you get a reliable machine for tough jobs.

|

Feature |

Single Toggle Jaw Crusher |

Double Toggle Jaw Crusher |

|---|---|---|

|

Design |

Fewer parts |

More moving parts |

|

Throughput |

Higher |

Lower |

|

Maintenance |

Easier |

More complex |

|

Best For |

Softer materials |

Hard, abrasive materials |

Mobile Jaw Crushers

Mobile jaw crushers give you flexibility. You can move them from site to site. These crushers are great for short-term projects or when you need to crush different materials. Mobile jaw crushers save you money on transport because you bring the crusher to the rock, not the other way around. You set up fast and start working quickly.

-

Mobile jaw crushers fit small to medium jobs.

-

You can use them for many types of rock.

-

They help you cut down on hauling costs.

Stationary Jaw Crushers

Stationary jaw crushers stay in one place. You use them for big, long-term projects. These jaw crushers handle large volumes and heavy materials. They last a long time and need less frequent maintenance. If you want a heavy duty jaw crusher for a fixed plant, NHI has models built for high capacity and durability.

Note: Stationary jaw crushers cost less to run over time and work best for large, ongoing operations.

You should match the right jaw crusher to your job. Think about the types of jaw crushers, the material you need to crush, and how much you want to process. This choice helps you get the best results for your rock processing project.

Jaw Crusher Capacities

Choosing the right jaw crushers for your project depends on the size and capacity you need. Jaw crushers come in small, medium, and large models. Each type fits different jobs and rock processing needs.

Small Jaw Crushers

Small jaw crushers work well for lab use, small quarries, and pilot plants. You can handle feed openings up to 600×400 mm. These crushers process 16 to 200 tons per hour. You get reliable performance for light-duty tasks. Small jaw crushers suit jobs with limited space and lower production capacity. You can crush rocks with top sizes up to 152 mm and get final sizes as small as 3 mm.

|

Crusher Size |

Feed Opening (mm) |

Throughput (TPH) |

|---|---|---|

|

Small |

Up to 600×400 |

16-200 |

Tip: Use small jaw crushers for testing, sampling, or small-scale aggregate production.

Medium Jaw Crushers

Medium jaw crushers fit most construction and mining sites. You can process feed openings from 600×900 mm to 1200×1500 mm. These crushers deliver 200 to 800 tons per hour. Medium jaw crushers offer a balance between size and capacity. You can handle larger rocks and get consistent output. The design and jaw plate surface affect capacity. Corrugated plates improve crushing action and throughput.

|

Crusher Size |

Feed Opening (mm) |

Throughput (TPH) |

|---|---|---|

|

Medium |

600×900 to 1200×1500 |

200-800 |

-

Medium jaw crushers work best for ongoing aggregate production.

-

You can adjust settings for different rock types and densities.

Large Jaw Crushers

Large jaw crushers handle the biggest jobs. You can use feed openings exceeding 1200×1500 mm. These crushers reach 800 to 1,500+ tons per hour. Large jaw crushers suit high-volume mining and heavy-duty rock processing. You get maximum production capacity for tough materials. For larger-scale operations, you may need other crushers like cone or gyratory types.

|

Crusher Size |

Feed Opening (mm) |

Throughput (TPH) |

|---|---|---|

|

Large |

Exceeding 1200×1500 |

800-1,500+ |

Note: Jaw crushers work best for small to medium projects. For very large operations, consider other crusher types.

Jaw crushers give you flexibility in feed size and output. Actual production capacity changes with rock type, density, and feeding arrangements. You should match the jaw crusher size and capacity to your specific rock processing needs.

Crusher Selection

Picking the right jaw crushers helps you do your job well. You need to think about what kind of rock you want to crush. You also need to know what your project needs. This part will help you learn what to look for.

Material Factors

The rock you use changes how your jaw crushers work. Hardness and abrasiveness are important to check. Hard rocks like granite wear out jaw plates faster. Softer rocks like dolomite are easier to crush and last longer. The table below shows how some rocks compare:

|

Rock Type |

Unconfined Compressive Strength (MPa) |

Point Load Strength (MPa) |

Crushing Time (s) |

|---|---|---|---|

|

Granite |

101.67 |

6.43 |

21.0 |

|

Dolomite |

30.56 |

0.95 |

5.0 |

|

Limestone |

N/A |

N/A |

N/A |

|

Marble |

N/A |

N/A |

N/A |

Note: Hard and rough rocks wear out jaw plates faster. This means you might have to change parts more often. You should also think about wet or sticky rocks. These can block the crusher and make it work less well.

How hard and rough the rock is changes how long your jaw crushers last. Hard rocks make jaw plates wear out faster. You might see chisel marks and cracks when crushing tough rocks. Always check your rock before picking a jaw crusher.

Application Needs

You need to match your jaw crushers to your job. Each job needs something different. Mining uses jaw crushers for hard and rough rocks. Construction jobs need crushers that can do many things, like break concrete or make road base.

Here is a table that shows what different jobs need:

|

Application Need |

Description |

|---|---|

|

Material Type |

Jaw crushers work well for hard rocks like granite and recycled concrete. |

|

Primary Crushing |

They are good for first crushing, making big rocks smaller. |

|

Operating Costs |

They cost less to run because they have fewer moving parts. |

|

Limitations |

They do not work well for making very small pieces. You may need other crushers for that. |

|

Contaminated Material Performance |

They do not work well with rocks that have clay, dirt, or metal in them. |

You should also think about the size of the rocks you put in and the size you want after crushing. Here are some tips:

-

The biggest rock you put in should be 80% of the jaw crusher’s opening.

-

The type and size of your rocks help you pick the right crusher.

-

If you need smaller pieces, you might need another crusher.

Jaw crushers are best for first crushing and big rocks. If you want smaller pieces, you may need a second crusher.

Selection Steps

You can follow these steps to pick the best jaw crushers for your job:

|

Criteria |

Description |

|---|---|

|

Stage of Crushing |

Find out which step of crushing you need. |

|

Material Properties |

Think about how hard and rough your rocks are. |

|

Dimensions |

Measure the biggest length, width, and thickness of your rocks. |

|

Granulometric Requirement |

Decide what size you want after crushing. |

|

Capacity |

Figure out how much you need to crush each hour. |

You can also use this checklist:

-

Find out which step of crushing you need.

-

Check how hard and rough your rocks are.

-

Measure the size of your rocks.

-

Decide what size you want after crushing.

-

Set how much you need to crush.

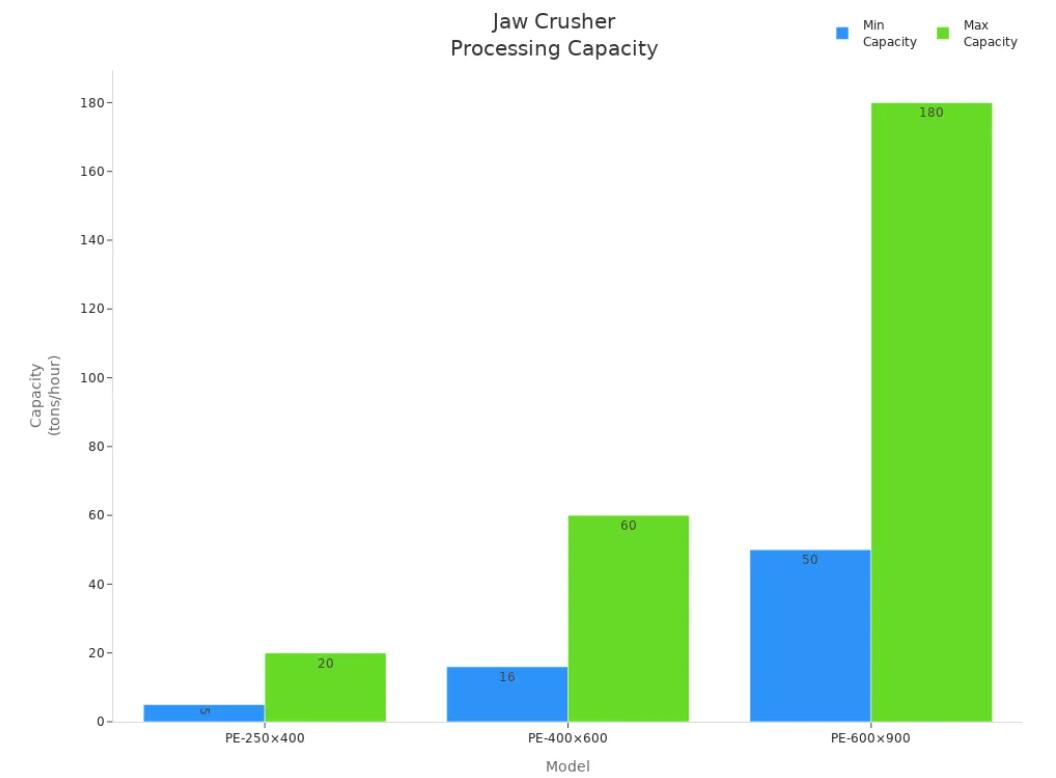

The table below shows some jaw crusher models, how much they can crush, and what they are good for:

|

Model |

Processing Capacity (tons/hour) |

Maximum Feed Size (mm) |

Application Scale Core |

Application Scenarios |

|---|---|---|---|---|

|

PE-250×400 |

5-20 |

~210 |

Small |

Laboratories, small quarries, mobile crushing, extra jobs |

|

PE-400×600 |

16-60 |

~340 |

Small and medium |

Sand and gravel, construction waste |

|

PE-600×900 |

50-180 |

~500 |

Medium and large |

Big sand and gravel jobs, mines, large projects |

Tip: For mining, pick jaw crushers that can crush hard and rough rocks. For building jobs, choose crushers that can do many things like breaking, recycling, and getting sites ready.

You should always match the jaw crusher type and size to your job. This helps you work better and spend less money. If you crush hard rocks, a heavy duty jaw crusher gives you more power and lasts longer. For softer rocks or small jobs, a regular jaw crusher is enough.

When you follow these steps, you work better and pick the right crusher. You also have less downtime and get more from your equipment.

Jaw Crusher for Rock Applications

Hard and Abrasive Materials

When you crush hard and rough rocks, the job is tough. A jaw crusher for rock gives strong crushing power at the start. You can use machines like JXSC Jaw Crushers or Komatsu BR380JG-1E0. These crushers have deep chambers and crush rocks well. You can change the settings to get different sizes. The Komatsu BR380JG-1E0 has a hydraulic system for better work.

|

Model |

Throughput (tons/hour) |

Features |

|---|---|---|

|

JXSC Jaw Crushers |

N/A |

Easy to use, deep chamber, strong crushing, adjustable settings |

|

Komatsu BR380JG-1E0 |

50-240 |

Hydraulic protection, works well, made for tough rocks |

Jaw crushers are used first to crush granite, basalt, and other hard rocks. These machines help you start your work line well. Jaw crushers cost less to run and last longer than cone or gyratory crushers for first crushing. Cone crushers are better for making smaller pieces later. Gyratory crushers also crush hard rocks but need more room.

Soft and Friable Materials

If you crush soft and crumbly rocks, jaw crushers still work great. They save energy and work fast for first crushing. Jaw crushers make less dust and fewer tiny pieces. This keeps your site clean and saves money on extra work. You can use jaw crushers for soft chalk, phosphate, or old asphalt.

|

Feature |

Benefit |

|---|---|

|

Material adaptability |

Works with many rocks from hard granite to old asphalt and wears less than impact crushers. |

|

Low dust and fines output |

Makes less dust and tiny pieces, so your site is safer and cleaner. |

|

High efficiency and energy saving |

Crushes rocks faster than some other crushers. |

|

Compact design |

Fits in small places like underground mines or mobile jobs. |

Jaw crushers work with many kinds of rocks and give strong crushing for first jobs. Impact crushers make more cube-shaped pieces, but jaw crushers crush more types of rocks and last longer for first crushing. Pick a jaw crusher for rock if you want steady work and control over rock size at the start.

You should pick jaw crushers that fit your material and job. Make sure the crusher can handle the amount you need. Always think about how much it costs to run. Safety is very important for everyone. You should also care about the environment. Manufacturers can help you find the best model. You need to plan for regular maintenance. Use the table below to help keep your crusher working well.

|

Consideration |

Description |

|---|---|

|

Regular Maintenance |

Stops problems and keeps the crusher working great |

|

Monitoring Wear |

Lets you change parts before something breaks |

|

Lubrication Practices |

Makes parts last longer and helps the crusher work |

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported