You use mobile track-mounted jaw crushers for tough jobs. These machines break concrete, asphalt, bricks, and rocks. Many people use mobile jaw crushers at building and demolition sites. You can crush and sort materials to reuse them. This means less trash goes to landfills and helps the planet. You can move the crusher to where you need it. This saves time and lowers moving costs. Mobile solutions are popular now. They give you more choices and use resources better.

Mobile Track-Mounted Jaw Crushers

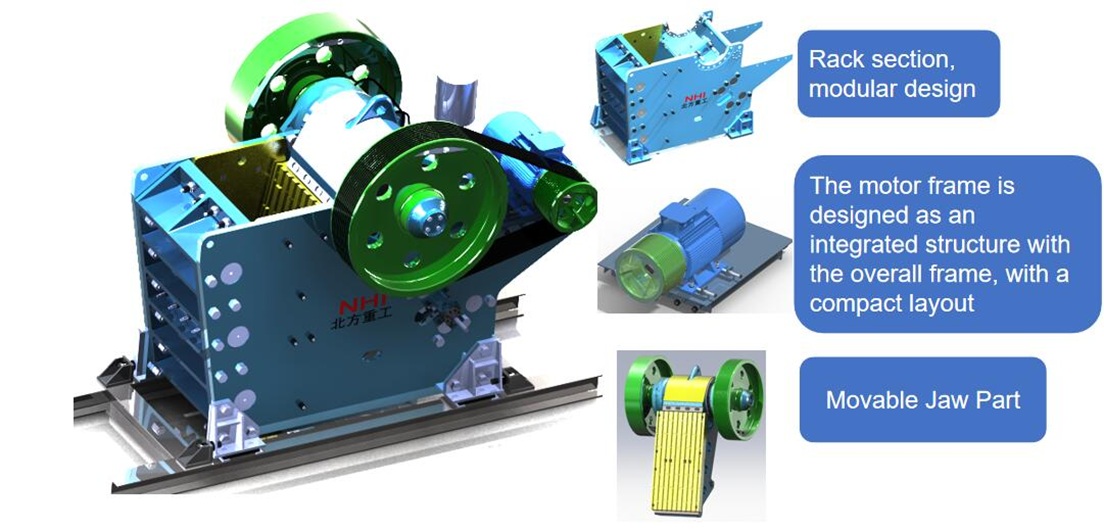

Key Components

Mobile track-mounted jaw crushers have many important parts. Each part helps the machine work better and last longer. The table below lists the main parts and how they help during use:

|

Component |

Contribution to Performance |

|---|---|

|

Elevated mouth opening |

Stops rocks from getting stuck, so work goes faster. |

|

Optimum jaw nip angle |

Makes sure the jaws wear evenly and shapes rocks well. |

|

Heavy duty track unit |

Keeps the machine steady and strong on rough ground. |

|

Dual power mode |

Lets you pick the best power source for your job. |

|

Electrical driven hydraulic |

Helps you set up and move the crusher quickly. |

These features help you work faster and keep the crusher running well. The heavy-duty track unit keeps the machine steady on bumpy ground. The dual power mode lets you use the right power for your site.

Applications

You can use rock stone crush machines in many fields. These machines can crush many types of materials. The table below shows where you use them and what they crush:

|

Industry |

Typical Materials Processed |

|---|---|

|

Construction |

Concrete, Asphalt, Aggregates |

|

Mining |

Raw Ore |

|

Recycling |

Demolition Debris |

|

Quarrying |

Aggregates |

|

Emergency Response |

Various Materials (e.g., rubble) |

You see these crushers at building sites, mines, and recycling places. They crush concrete, asphalt, and even raw ore. Because they do so much, many people choose mobile jaw crushers for their work.

Mobility Features

Mobile track-mounted jaw crushers are easy to move. They travel over rough ground without trouble. Here are some things that make them different from other crushers:

-

Can move over bumpy or soft ground: Tracks help them go anywhere.

-

Do not sink in soft dirt: Tracks spread out the weight.

-

Fast to set up: You can start working just a few hours after arriving.

You can set up quickly and move the crusher easily. This makes it simple to do different jobs in many places. Mobile jaw crushers let you work where and when you need.

Benefits of Mobile Jaw Crushers

Efficiency

You want your work to go fast. Mobile jaw crushers help you do this. These crushers let you crush materials right where you work. You do not have to wait for trucks to take things away. You can start crushing concrete, asphalt, or rocks as soon as you dig them up. This saves time and keeps your team busy. Mobile crushers let you work with different materials without stopping. You can switch from bricks to aggregates in just a few minutes.

The table below shows how mobile crushing plants and stationary ones compare for efficiency and other things:

|

Feature |

Mobile Crushing Plant |

Stationary Crushing Plant |

|---|---|---|

|

Flexibility |

Easier to move to new places |

Harder to move once set up |

|

Scalability |

Can use one or more units |

Can add more parts to make it bigger |

|

Environmental Impact |

Less impact because less moving needed |

More impact from getting the site ready |

|

Initial Cost |

Costs less to start |

Costs more to set up |

|

Operational Costs |

Can cost more in tough places |

Cheaper for big jobs |

Mobile jaw crushers help you work faster by crushing on-site. You do not need to move materials far, so you save time. You can use these crushers for many jobs like building, mining, and recycling. This helps you finish work faster and with less effort.

Using smarter and faster machines is important for C&D recycling. It helps when you need to work in small spaces.

Cost Savings

You want to spend less money on your projects. Heavy duty mobile jaw crushers help you save in many ways. You do not have to pay for trucks to move materials to another place. You can crush everything right where you are. This cuts down on moving costs, which can be half of your total costs with fixed crushers. You also save on workers because they do not have to move things far.

-

You do not need to buy expensive trucks or conveyor belts.

-

You pay less for workers to move materials.

-

Crushing on-site with mobile crushers saves time and money.

-

Studies show moving costs can be up to 50% of all costs with fixed crushers.

Mobile jaw crushers help you stick to your budget. You can use them for short jobs or long projects. You do not need to build anything permanent. You can move your crusher to new places and start working right away.

Flexibility

You need machines that can do many jobs. Mobile jaw crushers give you this flexibility. You can use them to crush hard rocks, old concrete, or broken buildings. You can move your crusher to different places without taking it apart. This makes it easy to work at new sites.

The table below shows how mobile jaw crushers are flexible and useful:

|

Feature |

Description |

|---|---|

|

Strong Mobility |

Move to new places without taking apart |

|

Versatility |

Crush hard rocks, old concrete, and more |

|

Direct Processing |

Crush materials right where you find them |

You can use mobile crushers for short or long jobs. You can switch between different uses like building, mining, or emergency work. You can start crushing as soon as you get there. This flexibility helps you finish faster and handle changes.

Environmental Impact

You want to help the environment while you work. Mobile jaw crushers help you do this. You can crush materials on-site, so fewer trucks are needed. This cuts down on pollution by 25% for each ton of rock. Electric and hybrid crushers also save up to 30% on fuel.

The table below lists the main ways mobile crushers help the environment:

|

Environmental Benefit |

Description |

|---|---|

|

Reduced Ecological Footprint |

Fewer trucks mean less pollution |

|

Dust and Noise Control |

Special systems keep dust and noise low |

|

Restoration Ease |

Easy to fix land after work because no big buildings are left |

Mobile jaw crushers make less noise and dust. You can use dust control systems to keep the air clean. You can fix the land quickly after your job because you do not build anything permanent. Mobile track-mounted jaw crushers help you follow the rules and keep people safe.

Tip: Electric mobile crushers help you use less fuel and make less pollution. You can pick these for greener work.

Mobile jaw crushers have many good points. You get faster work, save money, have more choices, and help the environment. You can use them for many jobs. You can move your crusher to new places and start right away. You can finish jobs faster and protect nature.

Mobile Crusher Operations

Setup

You need to follow steps when setting up mobile jaw crushers. Good setup helps you stay safe and work fast. First, check the ground and see if your equipment can reach the site. Pick the right mobile crusher for your material and job size. Gather your tools and make sure safety gear is ready. Put the crusher on stable ground and secure it. Connect power and hydraulic systems carefully. Calibrate the crusher and run a test to check how well it works.

|

Step |

Procedure |

Description |

|---|---|---|

|

1 |

Site Assessment |

Look at the ground and make sure equipment can get there. |

|

2 |

Equipment Selection |

Choose the best mobile crusher for your material and job. |

|

3 |

Initial Preparation |

Get your tools and set up safety gear. |

|

4 |

Positioning |

Place the crusher on flat ground and make sure it is secure. |

|

5 |

Connecting Power |

Connect electrical and hydraulic systems safely. |

|

6 |

Calibration |

Calibrate the crusher and run a test to check how well it works. |

Quick setup is important for mobile crushing plants. You can move and start working in new places fast. This makes mobile jaw crushers great for short jobs and far-away sites. You get more mobility and flexibility for many uses.

Usage

You want your mobile jaw crushers to work their best. Start by using pre-crushing screens to keep big pieces out. This helps you get even-sized material. Use automatic lubrication systems to keep the crusher running smoothly. Program crusher settings and use remote monitoring to adjust them for better results. Check wear parts every day and set the crusher chamber clearances for your material. Use lab tests to make processing better and improve your crushing circuit.

Here are good ways to use mobile jaw crushers:

-

Put in pre-crushing screens to keep big pieces out.

-

Use automatic lubrication systems to cut downtime.

-

Program crusher settings and watch them remotely.

-

Check wear parts every day.

-

Set crusher chamber clearances for your material.

-

Use lab tests to make processing better.

-

Make sure conveyor systems can handle the load.

-

Plan maintenance blitzes to refresh parts.

-

Keep spare parts on-site to cut downtime.

-

Train operators often to improve skills.

Mobile jaw crushers let you scale up for different jobs. You can use them for building, mining, recycling, and more. Their ability to work in many industries makes them great for far-away sites and short jobs.

Tip: Use remote monitoring to change crusher settings and work better.

Maintenance

You need to keep your mobile jaw crushers in good shape. Daily care helps you avoid breakdowns and keeps your crusher working well. Check lubrication points and add grease. Look at oil levels in bearings and fill up if needed. Look for cracks or wear on jaw plates. Clear any build-up in the crushing chamber before starting. Listen for strange sounds and walk around the machine to spot leaks or loose bolts.

Each week, tighten bolts, check belts, and look at toggle plates. Make sure the lubrication system works and look at liners for wear. Check safety guards and emergency stops. Each month, measure jaw plate wear, check bearings, and look at liners. Test hydraulic systems and check the main frame for cracks. Review maintenance logs to plan part replacements.

|

Frequency |

Maintenance Tasks |

|---|---|

|

Daily |

Check lubrication, look at oil, check for wear, clear chamber, listen for sounds, walk around for leaks. |

|

Weekly |

Tighten bolts, check belts, look at toggle plates, check lubrication, look at liners, check safety guards. |

|

Monthly |

Measure jaw plate wear, check bearings, look at liners, test hydraulics, check frame, review logs. |

Good lubrication is important. Use high-quality lubricants to stop wear and keep the crusher cool. Too much or too little lubrication can cause problems. Always check for loose bolts, look at jaw plates, and set the discharge opening right. Watch for vibrations and check the V-belt tension.

Common problems include strange noise, less crushing power, and too much vibration. Fix these by checking bolts, changing worn parts, and adjusting settings. Regular care keeps your mobile crusher ready for any job.

Safety

You must follow safety rules when using mobile jaw crushers. If the feeder or crusher starts by accident, you can get hurt. Material can fly out of the feeder or chute. Bad site conditions can make you slip or fall. Always turn off power before clearing blockages. Use hydraulic arms to clear bridged crushers. Treat stalled crushers as jammed and follow special steps to check them.

Follow these safety steps:

-

Turn off power before clearing blockages.

-

Use hydraulic arms to clear bridged crushers.

-

Treat stalled crushers as jammed and check carefully.

-

Follow safe operating steps and startup sequences.

-

Make sure alarms work and do not overload the crusher.

-

Keep safety guards in place and secure.

-

Do not go into the crusher area while it is running.

-

Watch dust and noise and control them.

-

Use lockout/tagout steps before maintenance.

-

Shut down and turn off the machine before clearing blockages.

-

Do a risk check before big maintenance jobs.

Environmental rules affect mobile crusher operations. You may need longer permits and must control dust and noise. Mining companies use hybrid and electric crushers to meet strict rules and lower emissions.

Note: Always wear safety gear and follow site rules to keep yourself and others safe.

Mobile track-mounted jaw crushers help you work safely and quickly. You get flexibility, better mobility, and fast setup for many jobs. Good care and safety steps keep your mobile jaw crushers working well and protect your team.

Top Models Comparison

Leading Brands

There are many well-known brands for mobile jaw crushers. These brands make strong machines with smart features. Some focus on saving energy. Others are good at automation and lasting a long time. Here are some top brands and what makes them special:

-

Rockster Austria International GmbH: You get new systems and strong power for demolition and screening.

-

Metso: You benefit from worldwide leadership in green technology and automation.

-

Sandvik: You rely on good engineering and tough equipment.

-

Terex: You see strong design and new ideas for mobile crushers.

-

Thyssenkrupp: You choose high power and care for the environment.

-

R.R. Equipment Company: You enjoy flexible jaw choices, remote control, and easy clearing for many jobs.

|

Brand |

Highlights |

|---|---|

|

R.R. EQUIPMENT COMPANY |

You can pick your Jaw, Track Drive System, and Turn-Key Design. It uses John Deere Diesel and Radio Remote Control. The feeder has variable speed. It works for rock, limestone, concrete, brick, asphalt, and more. You can add a Cross Belt Self Cleaning Magnet. The Jaw can be reversed to clear the crushing chamber easily. |

Features Overview

When you look at mobile jaw crushers, you see differences in technology, design, and size. Some models use hybrid drives to save fuel. Others have smart automation or easy care. Some have big openings for faster pre-crushing. Smart control systems help keep things safe.

|

Model Name |

Key Features |

Capacity |

Motor Power |

Unique Features |

|---|---|---|---|---|

|

Lokotrack® LT120E™ |

Electric mobile jaw crushing plant |

Superior |

N/A |

Great fuel savings |

|

McCloskey® J4R |

Good performance, new productivity features |

N/A |

N/A |

Better productivity |

|

Vanguard Plus series |

Good for aggregates or recycling |

N/A |

N/A |

Can be stationary or portable |

|

Boratas Mobile Jaw Crusher |

Tracked Hybrid Solution (Diesel-Electrical/Plug IN) |

N/A |

N/A |

Best hybrid solution |

|

ZCJ116 mobile jaw crusher |

Max capacity of 450t/h, smart controls |

450t/h |

N/A |

Can feed grain size up to 650mm |

|

Nordberg® C130™ |

Over one hundred years of engineering |

N/A |

N/A |

High performance and happy customers |

Some models have bolted frames, hydraulic adjustment, and telematics software. These features help with pre-crushing, short-term crushing, and safe work.

|

Model |

Key Features |

Applications |

|---|---|---|

|

Superior Liberty Jaw Crusher |

Bolted frame, better jaw, smart automation |

Mining, aggregates, recycling |

|

Astec FT2650 |

Big feed opening, hydraulic adjustment, easy controls |

Quarrying, mining, recycling |

|

Keestrack B3 |

Diesel-hydraulic or hybrid drive, overload safety |

Mining, quarrying, recycling |

Choosing the Right Model

You want the best mobile crusher for your job. Start by checking your material type and how hard it is. Look at the feed size and output size you need. Think about how much you want to crush now and later. Look at the crusher design, like single or double toggle. Make sure the mobile jaw crushers you pick are easy to care for and have good safety features.

|

Criteria |

Description |

|---|---|

|

Mobility |

Check the weight, size, and how easy it is to move. |

|

Crushing Capacity |

Make sure it can handle your material amount. |

|

Crushing Technology |

Pick the right type for your material. |

|

Maintenance and Serviceability |

Look for easy access and spare parts. |

|

Safety Features |

Choose crushers with emergency stops and safety standards. |

Tip: Always match your mobile jaw crushers to your project needs. You get better results when you pick the right model for your jobs, pre-crushing, and short-term crushing.

You get lots of good things when you use mobile jaw crushers at your site. The table below shows how these crushers help you:

|

Benefit |

Description |

|---|---|

|

Mobility |

You can move your crusher fast to any place. |

|

Efficiency |

You finish pre-crushing and work with less waiting. |

|

Cost Savings |

You spend less money on moving and setting up. |

|

Productivity |

You crush materials right where you work. |

|

Safety |

You use smart controls to keep everyone safe. |

Here are steps to pick the best mobile crusher:

-

Figure out how much material you need to crush.

-

Look at the size of your material before crushing.

-

Think about how much money you can spend and how big your job is.

-

Make sure your mobile jaw crushers work well with your other machines.

Mobile crushers are used more in recycling and building. You help nature by crushing and using waste at your site. Pick mobile jaw crushers for your next job to work better and faster.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported