You want to make a smart decision when you look at cone crusher price options. Choosing the right rock crusher means you must weigh both the first payment and the long-term costs. The cone crusher market keeps growing, with rising demand in regions like Asia-Pacific and new technology making machines more efficient.

-

The market size will move from $2.45 billion in 2024 to $3.2 billion by 2029.

-

New projects and better machines drive this growth.

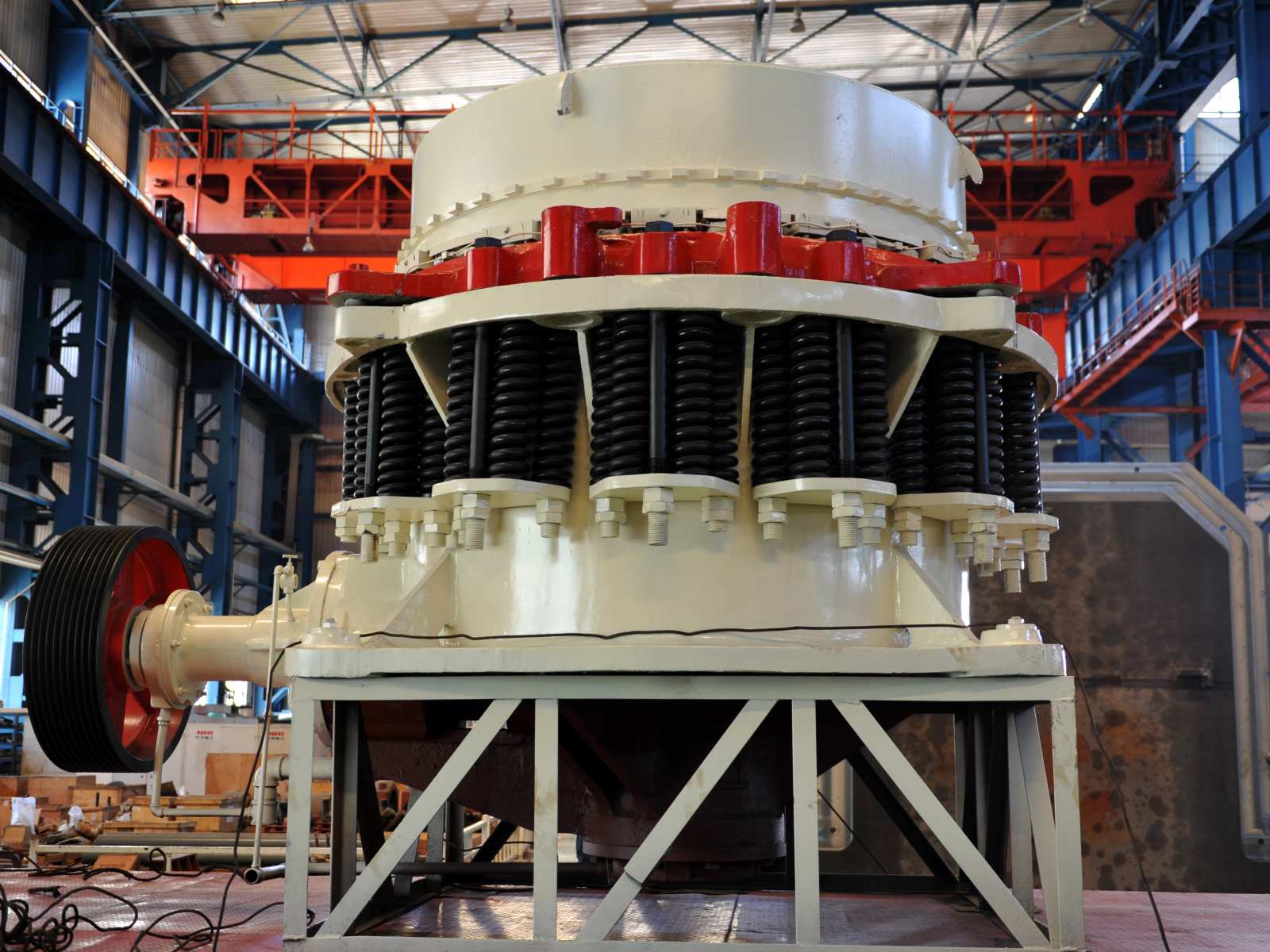

The price of a cone crusher is higher than that of an impact crusher, but it has a sturdy structure and a lower wear rate. Although the liner will wear over time, its service life is longer, avoiding the trouble of frequent replacement of parts.

You need a rock crusher buying guide that gives you real value for money. Focus on getting the best value for your investment, not just the lowest sticker price.

Key Takeaways

-

Know the full cost to own the machine. Think about setup, care, and power use, not just the first price.

-

Pick the best cone crusher for your job. Make sure the machine's size and parts fit what you need so you do not spend too much.

-

Look up many brands and models. Well-known brands often help more and keep their value longer, so they are a better buy.

-

Check the details closely. Look at crushing power, how much it runs by itself, and how much energy it uses to see what works best for you.

-

Talk with sellers. Try to get extras like a warranty or lessons to get the most for your money.

Cone Crusher Price Overview

Price Ranges

When you look for crushers, you see many prices. The cost changes with the model, features, and specs. Entry-level models start at about $100,000. New cone crushers can cost from $50,000 to more than $1,500,000. Single-cylinder hydraulic models cost between $80,000 and $1,500,000. Multi-cylinder hydraulic models cost from $150,000 to over $1,050,000. Used machines are usually cheaper, but you should check their condition and how well they were cared for.

Tip: Always look at both new and used cone crushers. You might save money if you find a used machine that is in good shape.

Here is a table to show the price ranges:

|

Model Type |

Price Range |

|---|---|

|

Entry-Level |

$100,000+ |

|

Single-Cylinder Hydraulic |

$80,000 - $1,500,000 |

|

Multi-Cylinder Hydraulic |

$150,000 - $1,050,000 |

|

Used Models |

Varies (lower than new) |

Types and Applications

You should learn about crusher types before you buy one. Cone crushers come in different types for different jobs. There are single-cylinder and multi-cylinder hydraulic models. These machines are used in mining, building, and recycling. Mining is growing fast, with market value going from 2.5 billion USD in 2024 to 4.5 billion USD by 2035. Building is also growing, moving from 1.5 billion USD in 2024 to 2.5 billion USD by 2035.

More people are moving to cities, so there is more need for roads and homes. Cone crushers help turn raw materials into the right size for these jobs. The price of a cone crusher often depends on what it will be used for. Machines for mining cost more because they work with harder stuff and bigger amounts. If you look at different crushers, you will see that cone crusher prices change based on what you need and how much you need to do.

Note: Always pick the cone crusher that fits your project. This helps you spend less and get the most for your money.

Factors Affecting Cost

When you look at cone crusher price, do not just look at the first price you see. Many things can change how much you pay and what you get. Knowing these things helps you make a smart choice and avoid problems later.

Capacity and Performance

How much a cone crusher can handle is important for its price. If you want a machine that works faster, you will pay more. Bigger machines can crush more rocks, but they cost more at the start.

How well the crusher works also changes the price. You should check how often you need to change parts, how much power it uses, and how often it needs fixing. Machines that use less power and have better designs cost more at first, but they save money later because they break less and make better rocks.

|

Performance Metric |

Impact on Costs |

|---|---|

|

Wear Parts Management |

Directly affects replacement frequency and costs. |

|

Power Consumption |

Higher consumption leads to increased operational costs. |

|

Maintenance Schedules |

More frequent maintenance increases downtime and costs. |

|

Crushing Chamber Design |

Influences efficiency and output, affecting overall costs. |

|

Crusher Capacity |

Affects throughput and operational efficiency. |

|

Discharge Size |

Impacts product quality and marketability. |

Tip: Pick a cone crusher that matches what you need. If you buy one that is too big, you spend more for nothing. If it is too small, your work will be slow.

Technology and Features

New cone crushers have smart technology that can make them cost more but work better. Things like automation, IoT, and special maintenance tools help you run your crusher with less trouble. These features help you fix problems faster, keep workers safe, and make your machine last longer.

-

Automation: Makes the crusher work better and break less.

-

IoT Connectivity: Helps you track data and see how the machine works.

-

Predictive Maintenance: Stops surprise breakdowns and saves money on repairs.

-

Regulatory Compliance: Makes the machine meet rules, which can cost more.

Cone crusher automation gives you machine data for smart maintenance. This helps you use parts longer, stop breakdowns, and avoid big repair bills. It also keeps workers safe and helps your business make more money.

When you look at different crushers, check which features fit your job. Fancy features can cost more at first, but they often save you money later.

Material Quality

What the cone crusher is made of changes how long it lasts and how much it costs. Strong metals like manganese steel, high chrome iron, or special alloys cost more but last longer. If you pick liners made from tough steel like chrome-molybdenum, they are harder to break and last longer. These are good for tough jobs and mean you do not have to change parts as often.

|

Material Type |

Durability and Cost Impact |

|---|---|

|

Manganese Steel |

Standard wear resistance, lower cost. |

|

High Chrome Iron |

Improved wear resistance, moderate cost. |

|

Chrome-Molybdenum Alloy |

Superior toughness and wear life, higher cost. |

Picking the right metal for your job helps you spend less over time, even if it costs more at first.

Brand and Market

The company that makes the crusher and what is happening in the market also change the price. Big brands charge more because they are trusted and give better help and parts. You pay more, but you get good service and a machine that lasts.

Prices can go up or down depending on what is happening in the world. For example:

-

Market changes and where you live can make prices go up or down because of demand, competition, and new technology.

-

North America will have about 39.4% of the cone crusher market in 2025 because many people there need crushers for building and mining.

-

Asia Pacific is growing fast, with countries like India building more, so they need more crushers.

If you buy when everyone wants a crusher or from a place with few machines, you might pay more. Shipping costs also add to the price, especially if you buy from far away.

Note: Always look at offers from different companies and think about what is happening in your area and around the world before you buy.

If you know what changes the price, you can pick the best cone crusher for your job and budget.

How to Buy Cone Crushers

Assessing Needs

Before you buy cone crushers, know what your project needs. Think about what kind of material you want to crush. Decide how small you want the rocks to be. Figure out how much material you want to crush each hour. These things help you pick the right crusher. You do not want to pay for features you will not use.

You also need to think about how the crusher will work every day. The table below shows what you should check:

|

Key Requirement |

Description |

|---|---|

|

Operational Efficiency |

You want equipment that works a lot and does not break often. |

|

Compliance and Sustainability |

Pick machines that are good for the environment and follow the rules. |

|

Innovation and Future-Proofing |

Choose crushers that can get new upgrades later. |

|

Cost Transparency |

Look at all costs, like power and repairs, not just the price. |

|

Scalability |

Make sure the crusher can handle more work if you need it. |

|

Regulatory Compliance |

The crusher should meet all rules now and in the future. |

|

Long-Term ROI |

Think about how much money you save over time and how long the crusher lasts. |

Tip: Write down your goals, the size you want, and if you might need to crush more later. This list will help you look for the right crusher and avoid mistakes.

Comparing Specifications

After you know what you need, compare different crushers. Look at how strong each crusher is. Check if it has smart controls or needs to be run by hand. See how much it can crush and what materials it can handle. Make sure it can make the size you want.

Here is a table to help you compare:

|

Type |

Crushing Force |

Automation Level |

Applicable Materials |

Capacity Range |

Investment Cost |

|---|---|---|---|---|---|

|

Spring Cone Crusher |

Medium (spring buffer) |

Low (manual adjustment) |

Medium-hard materials |

10-300 tons/hour |

Low |

|

Single-Cylinder Hydraulic Cone Crusher |

High (adjustable hydraulic system) |

High (hydraulic automatic adjustment) |

Medium-hard to hard materials |

50-800 tons/hour |

Medium |

|

Multi-Cylinder Hydraulic Cone Crusher |

Ultra-high (multi-cylinder boost) |

High (smart hydraulics + PLC control) |

Hard to ultra-hard materials |

100-1500 tons/hour |

High |

|

Compound Cone Crusher |

High (combined crushing chamber design) |

Medium (partial hydraulic assistance) |

Medium-hard to hard materials |

30-500 tons/hour |

Medium |

You should also:

-

Figure out how much each crusher can crush.

-

Check if the company is known for good service.

-

Think about where you will put the crusher.

-

Look at how much energy it uses and if it is good for the environment.

Note: Always look at the specs side by side. This helps you find the crusher that fits your goals and the size you want.

Requesting Quotes

When you have a short list, ask suppliers for prices. Give them clear details so you can compare prices easily. Tell them the type, model, and what features you want. Say how much you want to crush and what size you need. Ask about new technology, how well it works, and if there are extra costs for shipping or setting it up.

Here is a table to show what to include:

|

Factor |

Description |

|---|---|

|

Type and Model |

Different crushers cost more or less based on what they can do. |

|

Configuration and Automation |

More automation can cost more but may save money later. |

|

Technology and Efficiency |

New tech can cost more at first but save money over time. |

|

Market Demand and Supply |

Prices can go up if many people want crushers or down if there are too many. |

|

Manufacturer and Brand |

Some brands cost more because they are known for good service. |

|

Location and Transport |

Shipping and where the company is can change the final price. |

Tip: Always ask for a list that shows what you are paying for. This helps you see what each part costs and compare offers.

Evaluating Support

Help from the company is important for saving money later. Check if the company gives training, spare parts, and help when you need it. Good support means your crusher will work better and break less.

Ask these questions:

-

Will they help set up the crusher and teach you how to use it?

-

How fast can they send you spare parts?

-

How quickly do they answer when you need help?

-

Do they offer regular check-ups or service plans?

A good company helps you get the most from your crusher. Good support means fewer problems and lower repair bills.

If you follow these steps, you will buy a cone crusher that fits your needs and budget. Always look at the total cost, not just the first price. Compare specs to find the best crusher for your job.

Total Costs of Ownership

When you look at cone crusher price, you must consider costs beyond the initial purchase price. The total cost of ownership includes everything you pay over the life of your cone crusher. This means you need to think about installation, maintenance, repairs, energy use, and even how much you can sell the machine for later. If you only focus on the price at the start, you might miss hidden costs that add up over time.

Installation and Setup

You pay more than just the sticker price when you buy a cone crusher. Installation and setup costs can include site preparation, foundation work, and connecting the crusher to power and other systems. If you choose a larger or more advanced model, setup costs may increase. You should always ask suppliers for a full breakdown of these costs before you buy.

Tip: Plan for installation costs early. This helps you avoid surprises and keeps your project on budget.

Maintenance and Repairs

Maintenance and repairs make up a big part of long-term costs. You need to replace wear parts, check the machine, and fix problems as they come up. Over five years, maintenance costs can reach $0.003 per ton, while repairs can add $0.06 per ton. After ten years, repair costs may rise to $0.09 per ton. If you pick a reliable cone crusher, you can lower these costs and keep your machine running longer.

|

Cost Type |

5 Years Cost/ton |

10 Years Cost/ton |

|---|---|---|

|

Maintenance |

$0.003 |

$0.003 |

|

Repair |

$0.06 |

$0.09 |

Energy and Operation

Energy use is another key part of total costs. Some cone crushers use less power because they have better designs or new technology. If you choose a model with high efficiency, you can save money every month. Lower operational costs and roi improve your bottom line. Always compare energy ratings when you look at different models.

Resale Value

You should also consider costs you can recover. The resale value of your cone crusher depends on how well you maintain it and the brand you choose. Used cone crushers lose value slower than new ones, especially if you take good care of them. Trusted brands hold their value better and make it easier to sell your machine later. New machines lose value quickly in the first few years, but buying used helps you avoid this loss.

-

Well-maintained machines keep their value longer.

-

Trusted brands make it easier to resell.

-

Used crushers lose value slower than new ones.

-

Buying used helps you avoid the biggest drop in value.

When you consider costs over the life of your cone crusher, you make smarter decisions. You get more value and avoid surprises that can hurt your budget.

Maximizing Value When You Buy

Negotiating Price

You can often pay less for a cone crusher if you use smart ways to talk with the seller. Try to build a good relationship with your supplier. This can help you get special deals and lower prices. Ask if you can get extra things like longer warranties or training included. If you buy more than one machine, you might get a better price. Always look at what other companies charge before you talk about price. This gives you more power when you ask for a deal. Talk about discounts or ways to pay over time during your talks.

-

Ask for extra services like warranties to save money.

-

Use your good relationship with the supplier to get better deals.

-

Check prices from other brands to help your case.

-

Try to get discounts, especially if you buy many machines.

Tip: Being friendly with your dealer can help you get special deals and save money.

Financing Options

Financing helps you pay for a cone crusher over time. Many suppliers let you pay in small amounts for 24 or 36 months. Some companies give you clear quotes and let you pick how you want to pay. You can use a loan calculator to see how each choice changes your payments. Section 179 tax savings let you take off up to $1.22 million in 2025, which can make your total cost lower.

|

Financing Option |

Description |

|---|---|

|

Loan Calculator |

Helps you see costs and savings for your buy. |

|

Section 179 Tax Savings |

Lets you take off up to $1.22 million in 2025 to lower your total cost. |

After-Sales Support

After-sales support makes your investment worth more. Pick a supplier who gives training, sends spare parts fast, and checks your machine often. Good support means your crusher breaks less and costs less to fix. Ask if the company has service plans or can help you with problems. Good after-sales help keeps your cone crusher working longer and protects your money.

Planning for Upgrades

Plan for upgrades to make your cone crusher last longer and work better. Use OEM parts so everything fits and works right. Upgrades like better bowl controls can make your crusher work up to 20% better and keep workers safe. Keep the crusher speed and feed right to stop damage and save on repairs. Work hardening manganese liners can last up to 30% longer. Feeding the crusher all the time helps parts last longer and helps you earn more.

-

Buy OEM parts to help your equipment last longer.

-

Upgrade controls to make your crusher safer and work better.

-

Watch crusher speed and feed for best results.

-

Use the right liners to spend less on repairs.

Note: Planning upgrades and doing regular checks helps you get more value from your cone crusher and lowers your total cost over time.

You can buy a cone crusher in a smart way if you follow simple steps. First, know what you need and look at the specs of each machine. Do not just look at the first price you see. Think about all costs, like fixing the machine and selling it later. Try not to make mistakes like missing market changes or not asking for a better deal. Pick sellers who are trusted, have certificates, and help you quickly. If you look at many offers, you will get the best deal and do well for a long time.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported