A bridge type scraper reclaimer from Nhiglobalequip is an essential piece of bulk material equipment, designed to move large volumes of bulk material quickly and with precision. This type of bulk material equipment not only improves the speed of material handling but also enhances the mixing and blending of materials in your stockyard. The demand for bridge type scraper reclaimers is rising rapidly, with the market valued at USD 1.8 billion in 2023 and projected to reach USD 3.4 billion by 2032. Nhiglobalequip manufactures high-performance bridge type scraper reclaimers that set the standard in the industry.

| Metric | Bridge Type Scraper Reclaimer | Double Bucket Wheel on Bridge Reclaimer |

|---|---|---|

| Average Reclaiming Capacity | Higher | Lower |

| Residual Material | None | About 8% |

| Total Reclaiming Time | Faster | Slower |

| Degree of Homogenization | High | Lower |

Key Takeaways

- Bridge type scraper reclaimers help move lots of material fast. They work well in places like mines and cement plants. These machines make the job easier and quicker.

- You need to check and oil your reclaimer every day. This helps keep it working well for a long time. Taking care of it stops problems before they start.

- Picking the right size and model for your site is important. It helps the reclaimer work better and saves time. The right choice makes everything run smoothly.

Bridge Type Scraper Reclaimer Overview

What Is a Bridge Type Scraper Reclaimer

A bridge type scraper reclaimer helps move and mix lots of bulk material in a stockyard. The machine sits on a bridge that goes over the pile. It moves on tracks, so it can travel along the whole pile. Its main job is to pick up material and put it onto a conveyor for more work or to move it somewhere else.

This machine looks different from other reclaimers. It does not use bucket wheels or drums. Instead, it has a scraper chain with buckets or blades. The chain moves along the bridge and scrapes material from the pile. Then, it puts the material onto a conveyor. You can see the main features of this machine in the table below:

| Characteristic | Description |

|---|---|

| Operational Principles | Made for fast reclaiming of bulk materials, moves on a track. |

| Key Components | Has a bridge, scraper chain with buckets or blades, drive units, and control systems. |

| Advantages | Handles big amounts, works with different particle sizes, and keeps dust low. |

| Applications | Used in mining, cement making, and power plants for moving many kinds of materials. |

You will find bridge type scraper reclaimers where people need to handle coal, ore, limestone, or other bulk materials. These machines help keep work going by moving and mixing material quickly.

Key Features and Benefits

When you pick a bridge type scraper reclaimer, you get many helpful features. These features make your work faster and easier. Here are some of the main features and benefits:

- The scraper chain lets the machine keep working and mixing material all the time. You get a steady flow with few stops.

- The bridge makes the machine stable and covers the whole pile. This helps you get even mixing and blending.

- The parts are made from strong materials like special polyurethane or tough steel. This helps the machine last longer, even in hard places.

- Many new bridge type scraper reclaimers have IoT sensors. These sensors watch how the machine works and warn you about problems early.

- The drive system often uses variable frequency drives (VFDs). These let you control the scraper chain speed, which saves energy and lowers wear.

- Checking the machine and adding oil often keeps it working well. You can stop most problems by looking for worn parts and keeping everything oiled.

You can compare bridge type scraper reclaimers with other types, like bucket wheel reclaimers, in the table below:

| Feature | Bridge Type Scraper Reclaimer | Bucket Wheel Reclaimer |

|---|---|---|

| Mechanism | Scrapers on a chain | Bucket wheels |

| Blending Capability | Yes | No |

| Structural Configuration | Bridge structure | Varies (can be portal) |

Tip: If you want your stockyard to work better and mix materials well, a bridge type scraper reclaimer is a great pick. Its design helps with different particle sizes and keeps dust down, so your work area stays cleaner and safer.

Taking care of your bridge type scraper reclaimer is very important. Checking and oiling it often makes it last longer. This also helps you get the most from your machine. By choosing this reclaimer, you make your bulk material handling faster, safer, and more reliable.

How Bridge-Type Scraper Reclaimer Works

Operating Principles

A bridge-type scraper reclaimer moves over the top of a stockpile. The bridge sits on rails and goes along the pile. The scraper chain has blades or buckets. It moves back and forth across the bridge. This chain scrapes material from the pile’s surface. It pushes the material to the middle. The material falls onto a feeding belt conveyor under the bridge.

You can change how fast the scraper chain moves. You can also control how fast the bridge travels. This lets you pick how much material you want to reclaim. Many reclaimers have computer controls. These controls help you set the reclaiming speed. They also let you watch how the machine works. Some machines can reclaim up to 4,000 tons each hour. There are single, twin, or double boom models. These choices help you work with different yard shapes and materials.

A bridge type scraper reclaimer is good for even blending. The scraper chain moves thin layers of material. This mixes the material as it moves. You get a more even product. The design keeps dust low. It also stops the material from separating. The machine can work for a long time without stopping.

Note: Automatic operation helps you blend better. This keeps your bulk material quality steady.

Main Components

A bridge-type scraper reclaimer has many important parts. Each part does a special job. The table below shows the main parts and what they do:

| Component | Function |

|---|---|

| Girder | Holds up the machine and keeps it steady. |

| Material Rakes | Collects material and moves it to the feeding belt conveyor. |

| Tower Frame | Gives strength and support to the reclaimer. |

| Feeding Belt Conveyor | Takes the reclaimed material away for more work. |

| Oil Cylinder | Moves the rakes from side to side to work faster. |

| Scraper Group | Stops material from spilling and protects the conveyor. |

These strong parts make the bridge type scraper reclaimer last a long time. The machine uses tough steel and special materials for the scraper chain and blades. This means you do not need to fix it often. You also get better performance.

- The girder and tower frame make the machine strong.

- The material rakes and scraper group move the bulk material.

- The oil cylinder lets you move the rakes quickly.

- The feeding belt conveyor helps the material leave the pile smoothly.

Some reclaimers have trippers. These let you skip the machine and send material straight from unloading to loading. Some models can work with piles on both sides using booms. Back stacking helps you handle material better.

Tip: Pick a bridge-type scraper reclaimer with automatic controls and speed settings. This helps you blend well and makes your work easier.

Strong parts, smart controls, and good design make the bridge-type scraper reclaimer a great choice for bulk material handling. You get high capacity, less fixing, and good blending every time you use it.

Design Features

Models and Configurations

There are many models of bridge type scraper reclaimers. You can pick one that fits your yard and material. NHI is a top company that sells many choices. Some models work best in flat stockyards. Others are made for piles that are sloped or uneven. Horizontal models are good for big, flat yards. Inclined and head-up models help with sloped piles. Some special models are made for cement, brick, or grain storage.

Here is a quick look at some models you can get:

| Product Name | Price Range | Key Attributes |

|---|---|---|

| SINOMALY High-Capacity Chain-Driven Side Scraper Reclaimer | $136,374 | High-capacity, chain-driven, for cement clinker/bulk material |

| Full Bridge Sludge Removal Scraper | $30,000 - $34,000 | Full bridge design, sludge and scum removal, wastewater use |

| Efficient Scraper Reclaimer for Brick Production | $25,000 - $30,000 | Auto-control, continuous raw material take, brick lines |

| Crawler Type Combined Grain Scraper Reclaimer | $950 - $1,000 | Crawler type, grain (rice/wheat/corn), CE Certified, silo use |

NHI knows how to help you pick the right machine. You can get high capacity or special features for your job.

Automation and Control

Modern bridge type scraper reclaimers have smart control systems. These systems help you get the best results. Automation lets you set up how the machine works. You can make it start and stop by itself. You can also watch the machine from far away.

| Feature | Description |

|---|---|

| Programmable reclaiming sequences | Automated, customizable material reclaiming processes |

| Real-time positioning systems | Accurate location tracking during operation |

| Auto-start and shutdown procedures | Automatic operation without manual work |

| Remote monitoring and diagnostics | Off-site oversight and troubleshooting |

These features help you in many ways:

- Automation means you need fewer workers in the yard, so it is safer.

- Control systems use sensors and software to run in real time.

- Safety tools like emergency stops and anti-collision keep people safe.

- Smart sensors tell you early if something needs fixing, so you can stop problems.

Automation is more important when you handle lots of material. NHI’s control systems help you work faster, safer, and with less hard work.

Applications in Bulk Material Handling

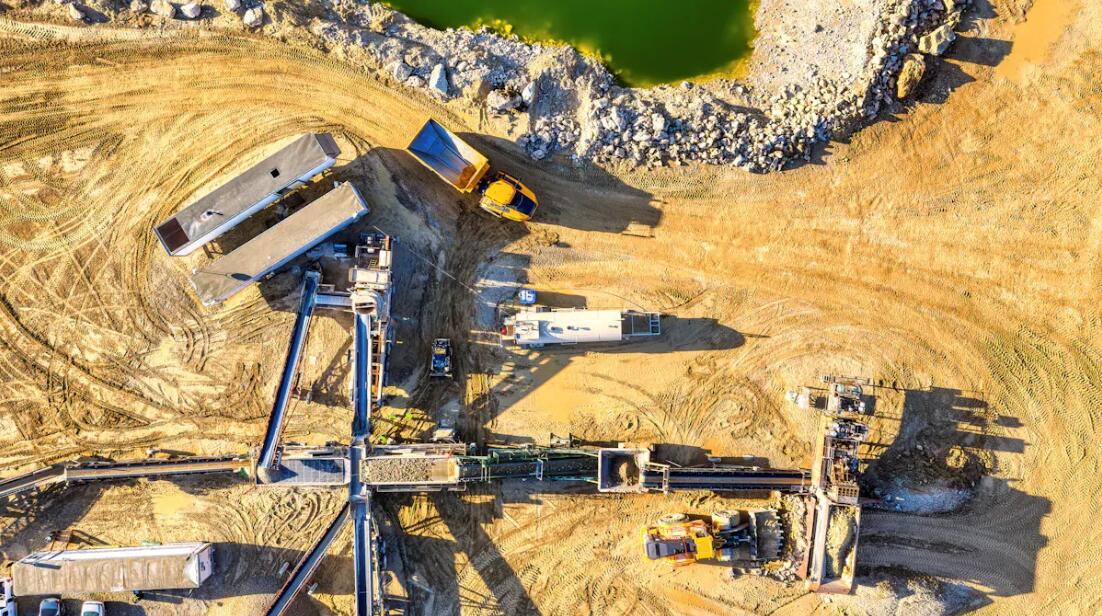

Common Materials and Industries

Bridge-type scraper reclaimers are used in many industries. These machines help move and mix big amounts of material each day. The main industries that use them are mining, power generation, and cement production.

These reclaimers handle many kinds of bulk materials. Some examples are:

- Copper concentrate

- Coal

- Urea

You can also use them for iron powder, limestone, and raw coal. They work well with many materials. This makes your work easier and helps you do more.

Blending and Homogenization

Bridge-type scraper reclaimers are important for mixing bulk materials. You use them to blend raw materials before they are processed. This helps you get good quality and even material. The circular homogenizing bridge scraper stacker/reclaimer lets you stack and reclaim without stopping. You get full-section reclaiming, which is needed in building materials, coal, metallurgy, and power plants.

Advanced automation and sensors help you watch the process as it happens. You can change the reclaiming speed and how much you blend. This makes your work faster and keeps quality high. The spiral blade drum design mixes everything evenly. You get the same results every time. These machines can reclaim up to 6,500 tons per hour. Automated features help you keep a steady flow, which makes your work better and faster.

Tip: You can work better by using bridge-type scraper reclaimers for fast reclaiming and mixing. This helps you follow industry rules and improve your bulk material handling.

When you use these reclaimers, your product quality gets better. Your work also runs more smoothly. They help you reach your goals for doing more and working well with bulk materials.

Selecting the Right Reclaimer

Sizing and Capacity

Choosing the right size and capacity for your bridge type scraper reclaimer helps you reach your material handling goals. You need to match the reclaimer to your operation’s needs. If you pick a model that is too small, you may slow down your work. If you choose one that is too large, you might waste money and space.

Here is a table to help you see what to consider:

| Factor | Description |

|---|---|

| Capacity Requirements | Decide how much material you need to move each hour. Different reclaimers offer different capacities. |

| Stockpile Size and Shape | Check the size and shape of your stockpile. This affects the reach and height you need. |

| Material Characteristics | Think about density, moisture, and how rough the material is. These affect the design. |

| Automation Requirements | Choose how much you want the machine to run by itself. |

| Space Constraints | Look at how much room you have. Some reclaimers fit better in tight spaces. |

| Budget | Plan for both the cost to buy and the cost to keep it running. |

You should always match the reclaimer’s capacity to your daily needs. This helps you keep your operation running smoothly and boosts efficiency.

Site and Material Considerations

Before you select a reclaimer, you need to look at your site and the materials you handle. Each site is different. Some have lots of space, while others are tight. The type of material you move also matters.

- Check your site layout and how much space you have for installation.

- Look at the size, shape, and weight of your material.

- Think about how wet, sticky, or rough the material is.

- Pay attention to dust, noise, and energy use at your site.

Tip: When you match the reclaimer to your site and material, you get better performance and longer machine life.

Reclaimers that fit your site and material will help you work faster and safer. You will also see better efficiency in your bulk material handling.

Maintenance and Troubleshooting

Routine Maintenance

You need to take care of bridge type scraper reclaimers often. This helps them work well and not break down. Doing regular checks makes the machine last longer. Here are some things you should do:

- Look at the machine every day for leaks or damage.

- Check oil, coolant, and hydraulic fluid levels. Add more if needed.

- Put grease on moving parts as the maker says.

- Look at tires or tracks for cuts or cracks. Make sure they are tight or have enough air.

- Check scraper blades. Change them if they are worn or broken.

- Watch for leaks in the hydraulic system. Look at hoses and connections.

- Test the electrical controls to see if they work right.

Tip: Use a checklist to help you remember these steps. This keeps your reclaimer working well.

Common Issues

Sometimes, problems can happen when you use the machine. Knowing what to look for helps you fix things fast. Here is a table that shows common problems, why they happen, and how to fix them:

| Issue | Cause | Solution |

|---|---|---|

| Chain tension and wear | Not enough grease or too much weight | Check often, add grease, tighten chain, change old chains |

| Scraper blade damage or misalignment | Weak blades or things stuck in the pile | Use strong blades, check tracks, put up screens |

| Bridge skewing or instability | Motors not even or wheels worn out | Fix motors, check the frame, watch alignment |

| Electrical and control faults | Dust or old computer programs | Cover parts, use surge protectors, update programs |

| Hydraulic failures | Seals worn out or dirty oil | Keep oil clean, check hoses, watch pressure |

| Excessive noise or vibration | Bolts loose or bearings worn | Tighten bolts, grease bearings, check balance |

You can stop many problems by cleaning under the machine. Adjust track tension and change old parts. Always follow the maker’s rules for weight and attachments. These steps help your reclaimer work better and last longer.

You can see that a bridge type scraper reclaimer helps you move bulk material better. Reclaimers make your work faster, easier, and safer.

| Feature | Description |

|---|---|

| Efficiency | Moves material smoothly and without stopping |

| Versatile Use | Used in mining, power plants, and cement making |

| Durability | Lasts a long time and needs little fixing |

Pick the right reclaimer and use it the right way. Take care of it so your system works well and saves money. If you want to learn more, look at technical guides about reclaimers.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported