You can find five main types of coal mills in factories today: Ball Mill, Bowl Mill, Vertical Roller Mill, Hammer Mill, and Impact Dryer Mill. These mills crush coal for power, cement, steel, and chemical plants. Ball mills and vertical roller mills are important because they can process a lot of coal and save energy. The worldwide market for these machines is almost $5 billion every year, and Asia-Pacific buys the most. Picking the right coal mill helps you control energy costs and fit your factory’s needs.

Ball Coal Mill Overview

How This Coal Mill Works

A ball medium-speed coal mill grinds coal into fine powder. This powder is used for energy and in factories. The coal mill has a big drum that turns around. Inside the drum are steel balls called grinding media. When the drum spins, the balls go up and then fall down. The balls crush the coal by rubbing and breaking it. This uses kinetic energy and energy transfer. Coal goes in through a feed system. After grinding, it leaves through a discharge system. You can see the main parts of a coal mill in the table below:

|

Component |

Description |

|---|---|

|

Drum/Cylinder |

The main body that houses the grinding media and the material to be processed. |

|

Grinding Media |

Spherical or cylindrical objects (steel, ceramic, or composite materials) that facilitate grinding. |

|

Liners |

Protective layers inside the drum that prevent wear and improve grinding efficiency. |

|

Drive System |

Consists of a motor, gearbox, and a girth gear that rotates the drum. |

|

Feed Mechanism |

Introduces raw material into the mill, either via a spout feeder or helical scoop feeder. |

|

Discharge Mechanism |

Allows processed material to exit, commonly through overflow, grate, or center-peripheral discharge systems. |

There are three main motions inside the coal mill. These are cascading, cataracting, and centrifuging. These motions help the grinding media break the coal well. Medium speed coal mills like this one work steadily and give good results.

Advantages of Ball Coal Mills

A coal grinding ball mill has many benefits. It can handle many coal types and sizes. You can change how the coal mill works to fit your needs. The design is simple, so coal mill maintenance is easier. Ball coal mills give even particle size. This helps coal grinding efficiency.

Tip: Ball coal mills can grind a lot of coal, but they use more energy than some newer mills.

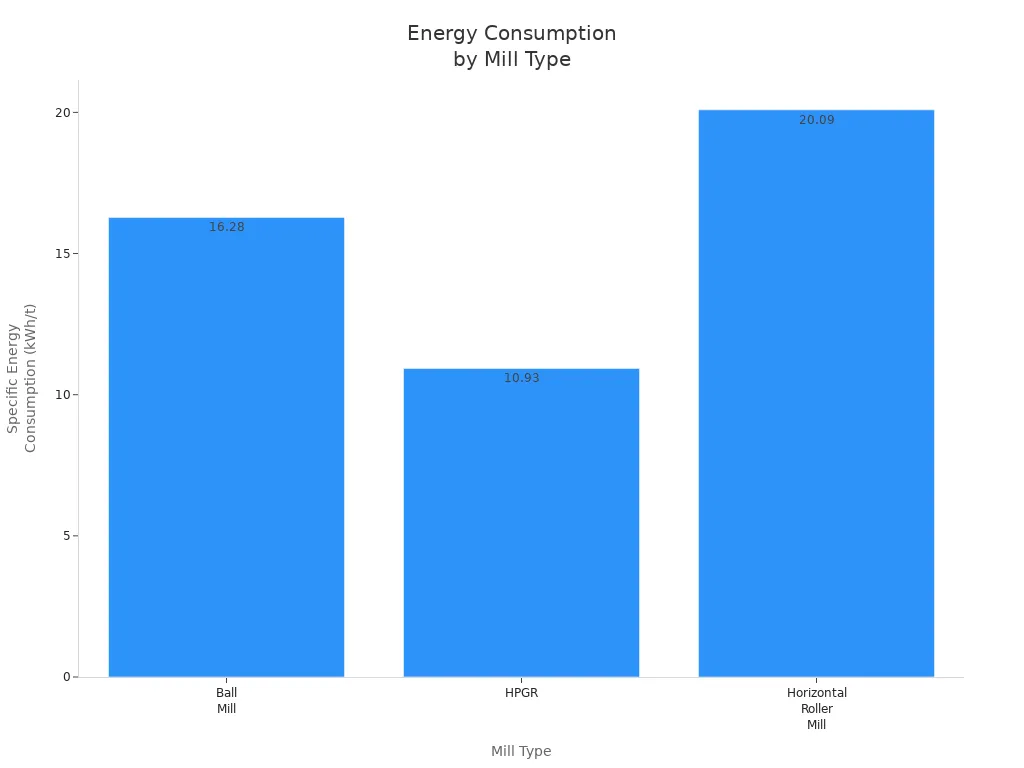

The chart below shows how much energy a ball coal mill uses compared to other mills:

You can see ball coal mills are not the most energy-saving. But they are still popular because they are reliable and flexible. Medium speed coal mills, like the ball type, are still used in many factories.

Industrial Uses

Many industries use the coal vertical mill machine. Power plants use this coal mill to crush coal for burning. In metallurgy, it helps make coke and other things. The building materials industry grinds limestone and other materials with this mill. Chemical plants and waste-to-energy places also use the coal grinding ball mill. The table below shows where you might use this coal mill:

|

Industry |

Application Description |

|---|---|

|

Power Industry |

Pulverizing coal to enhance combustion efficiency |

|

Metallurgy |

Producing coke and other materials |

|

Building Materials |

Grinding raw materials like limestone |

|

Chemical Industry |

Processing various chemicals and compounds |

|

Waste-to-Energy |

Conversion of waste materials into energy |

|

Material Recycling |

Recycling processes utilizing pulverized coal |

You can count on the coal grinding ball mill for steady work in tough places. If you want good coal grinding and reliable use, this coal mill is a strong choice. To get the best from your coal pulverizer mill, think about how the ball coal mill fits your needs.

Bowl Mill (Raymond/Vertical Spindle)

How the Bowl Coal Mill Operates

You use a bowl mill when you want steady and efficient coal grinding. This coal mill, also called a Raymond or vertical spindle mill, works with a spinning grinding table and heavy rollers. You feed raw coal into the center of the mill. The table spins, and centrifugal force pushes the coal outward. The grinding rollers press down on the coal, crushing it against the table. Fine coal particles rise with the air stream to the classifier. The classifier separates fine coal from larger pieces. Coarse coal falls back for more grinding. This process repeats until you get the right size.

Here is a table showing the main parts of this coal mill:

|

Component |

Description |

|---|---|

|

Rocker Arm Device |

Connects the grinding roller to the hydraulic system for pressure control. |

|

Classifier |

Uses high-speed airflow to separate fine and coarse coal particles. |

|

Grinding Table |

Rotates to move coal under the rollers for grinding. |

|

Grinding Roller |

Presses and grinds coal against the table surface. |

You can see how each part helps the coal mill in cement plant work smoothly. The coal grinding vertical pulverizer design lets you adjust settings for better performance.

Key Benefits

You get many advantages when you use a bowl coal mill. High-quality parts reduce friction and keep the grinding surfaces smooth. This means you use less energy and get a steady particle size. Improved seals help the coal mill run without leaks, so you get a stable process. You can also extend maintenance intervals from 8-10 months up to 12-18 months. This saves you time and labor. Predictive maintenance helps you spot problems early and avoid unplanned shutdowns. You can reduce outages by up to 40% with good monitoring.

Tip: Regular checks on rollers, classifier blades, and air seals keep your coal mill running longer and better.

Here are some key maintenance tasks for your bowl coal mill:

-

Inspect roller and bowl surfaces often.

-

Check classifier blades for wear.

-

Make sure air seals are tight.

-

Replace worn bearings.

-

Calibrate hot air dampers and feeder controls.

-

Use predictive maintenance tools.

Common Applications

You find bowl coal mills in many industries. Power plants use this coal mill to grind coal for boilers. Cement factories rely on it to prepare fuel for kilns. Steel plants use the mill to process coal for coke ovens. Chemical plants need steady coal grinding for their processes. Waste-to-energy plants also use this coal mill for fuel preparation. The bowl coal mill gives you reliable, fine coal powder for many uses.

You can trust this coal mill for high output and low downtime. When you need a coal mill that handles tough jobs and keeps your plant running, the bowl mill stands out as a top choice.

Vertical Roller Coal Mill

Working Principle

You use a vertical roller coal mill when you want to combine drying and grinding in one step. This coal mill takes in raw coal and moves it onto a large grinding table. Rollers press the coal against the table, crushing and grinding it into fine particles. The heat from the grinding process dries the coal at the same time. You do not need extra drying equipment. This makes the coal grinding vertical roller mill different from other mills. You can feed larger pieces of coal into this coal mill because it has a bigger feed port and higher grinding pressure. Raymond mills need smaller feed sizes and cannot handle wet coal as well. The coal grinding vertical roller mill lets you process wet coal and larger chunks without jams. You get a steady flow of fine coal for your plant.

Main Advantages

You gain many benefits when you choose this coal mill.

-

You save energy. This coal mill uses 30-40% less energy than a ball mill.

-

You get a better particle size. The coal mill gives you a more even and fine coal powder.

-

You can process different types of coal and even wet coal.

-

You reduce the number of machines needed for coal powder processing.

-

You lower your maintenance needs because the design is simple and strong.

Tip: If you want to cut energy costs and get high-quality coal powder, this coal mill is a smart choice.

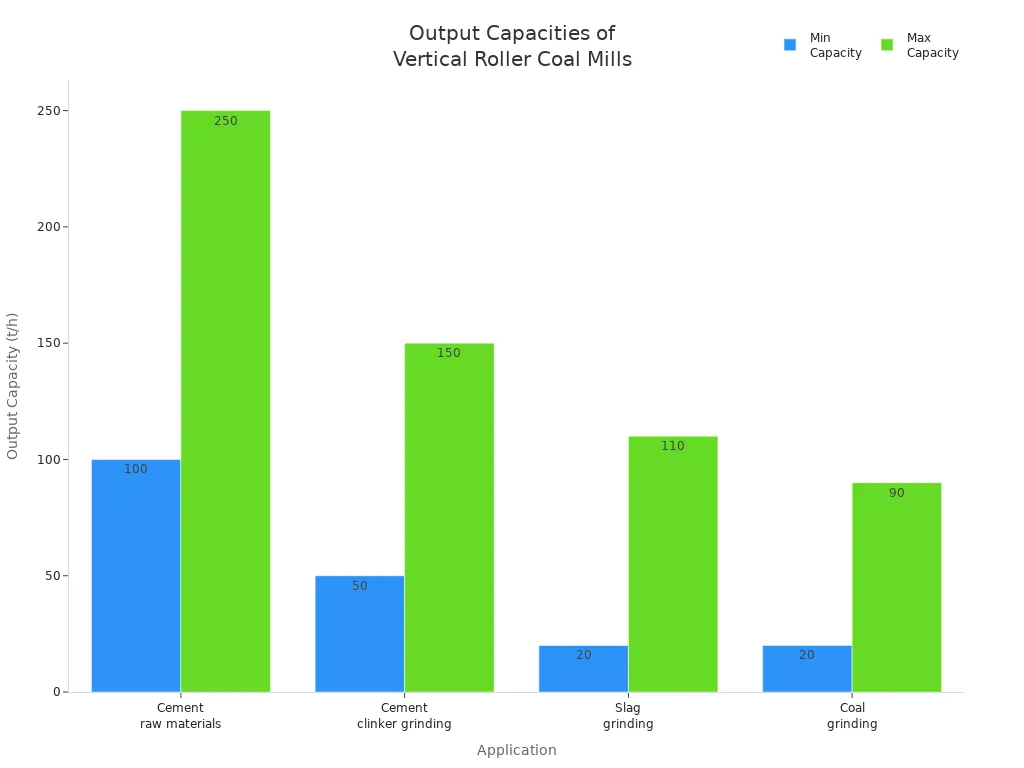

Industrial Applications

You find this coal mill in many industries. Cement plants use it for raw materials and clinker grinding. Power plants rely on it for coal powder processing. Steel and chemical factories also use this coal mill for their needs. You can see the typical output capacities in the table below:

|

Application |

Typical Output Capacity (t/h) |

|---|---|

|

Cement raw materials |

100-250 |

|

Cement clinker grinding |

50-150 |

|

Slag grinding |

20-110 |

|

Coal grinding |

20-90 |

You see this coal mill in chemical, metallurgy, non-metallic mining, cement production, and power generation. When you need reliable coal powder processing, this coal mill delivers steady results.

Hammer Coal Mill

How Hammer Mills Grind Coal

You use a hammer coal mill when you need to break coal into smaller pieces quickly. This coal mill uses high-speed hammers that spin inside a grinding chamber. The process starts with coal preparation. You may use a crusher to reduce the size of the coal before it enters the coal mill. The prepared coal drops into the grinding chamber by gravity. Inside, the hammers hit the coal again and again. Each impact breaks the coal into smaller particles. After grinding, the coal passes through sieves. Fine particles move on, while larger pieces return for more grinding. This method gives you control over the final coal size.

-

Coal preparation ensures the right size before grinding.

-

You feed the coal into the hammer coal mill chamber.

-

High-speed hammers strike the coal, breaking it down.

-

Sieves sort the coal by size, sending large pieces back for more grinding.

Benefits of Hammer Coal Mills

Hammer coal mills give you several advantages. You get a simple design that is easy to maintain. The coal mill handles many types of coal, even those with high moisture. You can replace worn parts like hammers and screens without much trouble. Regular checks keep your coal mill running smoothly and help you avoid long downtimes. The table below shows how often you should check or replace parts in your coal mill and why it matters.

|

Component |

Maintenance Frequency |

Benefits of Maintenance |

|---|---|---|

|

Hammers |

Replace when rounded |

Maintains efficiency and reduces downtime |

|

Hammer Rods |

Inspect with hammers |

Ensures optimal performance |

|

Screens/Grates |

Inspect regularly |

Achieves desired particle size |

|

Wear Plates |

Check thickness |

Extends equipment life |

|

Bearings |

Inspect for wear |

Prevents excessive heat and vibrations |

Tip: You can save money on repairs by checking your coal mill parts often. This keeps your coal mill efficient and reliable.

Typical Uses

You find hammer coal mills in many industries. Metals and mining companies use this coal mill for primary and secondary crushing. The agriculture sector uses the coal mill for grain processing and animal feed. You also see hammer coal mills in places that process agricultural waste. The table below shows the market share for each industry using this coal mill.

|

Industry |

Market Share (%) |

|---|---|

|

Metals and Mining |

32.1 |

|

Agriculture and Food & Feed |

30 |

-

Hammer coal mills are used for:

-

Crushing coal in metals and mining.

-

Processing grain and animal feed in agriculture.

-

Handling agricultural residues.

-

You can also use hammer coal mills in air-swept coal mills systems. Some plants combine a hammer coal mill with a coal pulverizing air swept ball mill to get the right coal size and moisture level. This setup helps you prepare coal for burning or further processing. When you need a flexible and cost-effective coal mill, the hammer type gives you strong results.

Impact Dryer Coal Mill

How Impact Dryer Mills Work

You use an impact dryer coal mill when you want to dry and grind coal in one step. This coal mill combines both processes in a single, automated system. You feed raw coal into the grinding chamber. Hot gas flows through the chamber at a controlled speed. The coal mill uses this hot gas to dry the coal as it moves. Inside, high-speed rotating hammers or impactors strike the coal. These impacts break the coal into smaller pieces. The coal mill increases the surface area of each particle, which helps the drying process work faster. You can adjust the feed rate with automatic variable-speed feeders. This keeps the coal mill running smoothly, even if the coal changes in moisture or size.

-

The coal mill integrates drying and grinding in a continuous operation.

-

Controlled velocity in the chamber helps the hot gas dry the coal.

-

Particle size reduction boosts drying by increasing surface area.

-

Automatic feeders adjust to keep the coal mill efficient.

Advantages in Coal Grinding

You get many benefits when you use an impact dryer coal mill. The coal mill saves time because it dries and grinds coal at once. You do not need separate machines for each step. This coal mill handles coal with high moisture, so you do not worry about wet coal slowing down your process. You can lower your energy use because the coal mill uses heat from the grinding process. The coal mill also gives you steady, fine coal powder for your plant. You can improve combustion efficiency and reduce costs. These are some of the main coal grinding plant advantages.

Note: You should check the grinding chamber and hammers often. This keeps your coal mill working at its best.

Use Cases

You find impact dryer coal mills in many industries. These coal mills help you prepare fuel for cement plants and cellulose factories. You use the coal mill to grind and dry coal for manufacturing. The coal mill also helps you cut costs by making combustion more efficient. You see this coal mill in power plants, chemical plants, and other places that need steady coal powder.

-

Fuel grinding and drying for cement and cellulose industries

-

Cost reduction by improving combustion efficiency

-

Used in power plants, chemical plants, and manufacturing

You can rely on the impact dryer coal mill when you need a flexible and powerful solution for coal grinding and drying.

Coal Grinding Pulverizer Mill System Comparison

Key Differences

You can see big differences between each coal mill when you look at how they grind coal, the quality of the product, and how much energy they use. The table below helps you compare the main features of each coal mill. This makes it easier for you to choose the right one for your coal grinding pulverizer mill system.

|

Mill Type |

Grinding Mechanism |

Product Quality |

Efficiency and Throughput |

Energy Consumption |

|---|---|---|---|---|

|

Ball Mill |

Impact & Attrition |

Fine, uniform powder |

High throughput, steady operation |

Moderate to high |

|

Bowl Mill |

Compression |

Consistent, fine powder |

Good control, reliable output |

Moderate |

|

Vertical Roller Mill |

Compression |

Very fine, even powder |

High efficiency, handles wet coal |

Low to moderate |

|

Hammer Mill |

Impact |

Coarse powder, more heat |

Fast, less control over size |

High (due to high-speed motors) |

|

Impact Dryer Mill |

Impact & Drying |

Fine, dry powder |

Combines drying and grinding, saves steps |

Moderate (uses process heat) |

You get smoother and more even coal powder from a vertical roller mill or bowl mill. Hammer mills work faster but give you coarser coal and use more energy. Ball mills handle many types of coal and give you steady results. Impact dryer mills help you save time by drying and grinding coal at once.

Best-Use Scenarios by Types of Coal

You need to match your coal mill to the type of coal and your plant’s needs. Some coal mills work better with certain types of coal or for special jobs like coal blending. Here are some tips to help you pick the best coal mill for your job:

-

Use a ball mill when you want to grind many types of coal, including hard and abrasive coal. This coal mill is good for power plants and steel mills.

-

Choose a bowl mill for steady, fine coal powder. This coal mill works well with bituminous coal and is common in power stations.

-

Pick a vertical roller mill if you need high efficiency and want to handle wet coal. This coal mill is great for cement plants and for coal blending with different moisture levels.

-

Try a hammer mill when you need fast grinding for softer coal or when you want to break up coal for blending. This coal mill is also good for plants that need quick size reduction.

-

Go with an impact dryer mill if you need to dry and grind coal at the same time. This coal mill is best for high-moisture coal and for plants that want to save space and energy.

Coal blending becomes easier when you use a vertical roller mill or hammer mill. These coal mills let you mix different types of coal for better fuel quality. Pulverizers like the bowl mill and ball mill give you steady results for most coal types.

You can get the best results by matching your coal mill to your coal type and your plant’s needs. This helps you save energy, improve coal blending, and keep your pulverizers running smoothly.

Choosing the Right Coal Mill for Types of Coal

Matching Mill Type to Coal Type

You need to match your coal mill to the properties of the coal you plan to use. Each coal mill works best with certain types of coal. The Hardgrove Grindability Index (HGI) helps you measure how easy it is to grind coal. If your coal has a high HGI, it is softer and easier to grind. Harder coal, with a low HGI, needs a stronger coal mill. Moisture content also matters. Some coal mills, like the vertical roller coal mill, handle wet coal better. The mechanical strength and brittleness of coal affect how fast you can crush it. More metamorphosed coal is harder and needs more power from your coal mill. You should always check the coal’s hardness, moisture, and grindability before choosing your coal mill.

-

HGI shows how easy it is to grind coal.

-

Harder coal needs a stronger coal mill.

-

Wet coal works better in mills that can dry and grind at once.

-

Brittleness and strength change how fast you can process coal.

Selection Tips

You want to pick the right coal mill for your plant’s needs. Start by looking at the coal’s characteristics. Think about how hard, wet, or abrasive the coal is. Decide how fine you need the coal powder. Check how much coal you need to process each hour. Make sure your plant can support the coal mill you choose. Some coal mills, like vertical roller mills, work best for large jobs. Ball mills may suit special coal types. Use the table below to help you compare your options:

|

Selection Criteria |

Description |

|---|---|

|

Coal Characteristics |

Look at hardness, moisture, and abrasiveness of the coal. |

|

Required Product Fineness |

Decide how fine the coal powder must be. |

|

Capacity Requirements |

Know how much coal you need to process. |

|

Infrastructure Availability |

Make sure your plant can support the coal mill. |

|

Mill Type Efficiency |

Vertical roller mills are efficient for big jobs; ball mills fit special needs. |

Tip: When you switch coal mills, you may face challenges. You might see lower grinding capacity or need to change your dosing system. Always check safety standards and use the right protection against fire and explosions. Keep your coal mill safe by following good maintenance and safety practices.

Choosing the right coal mill helps you get the best results from your coal and keeps your plant running smoothly.

You have read about five coal mill types and how they help your plant. Choosing the right coal mill makes your plant work better. The table below shows how much you can improve:

|

Improvement Type |

Percentage Change |

|---|---|

|

Mill Output |

18% |

|

Maintenance Intervals |

40% |

|

Energy Consumption |

-11% |

-

You use less energy and have less downtime. * You get better burning of coal and spend less on repairs.

If you want your coal grinding system to work its best, look at studies about control and automation. You can also talk to experts or read research about making your system run better and faster.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported