You use a tunnel boring machine to dig tunnels deep underground. It helps people dig in a safe and fast way. This big and modern machine is often called a TBM. It moves through soil and rock to make smooth tunnel walls. Many companies, like NHI, give these machines to projects everywhere. Today, the tunnel boring machine market is worth $7.50 billion. It is growing very fast.

Tunnel Boring Machine Overview

TBM Definition and Purpose

A tunnel boring machine is a very large machine. It digs tunnels deep under the ground. People call it a TBM. The TBM has a spinning cutterhead. This cutterhead breaks soil and rock. TBMs are used for long tunnels. These tunnels can be for subways or water pipes. NHI is a top company that makes TBMs. They build them for big projects all over the world.

The main job of a TBM is to make tunnel building faster and safer. TBMs can dig through soft dirt or hard rock. Old ways, like drilling and blasting, are slower. TBMs work without stopping. They do not need to blast or clear rocks. This means the ground above is not disturbed much. The tunnel walls are smooth. TBMs are best for long tunnels. Old methods are better for short tunnels.

TBMs let workers finish big projects faster and safer. The tunnel walls are smooth, so it saves time and money.

Here is a simple table that shows how TBMs and old methods are different:

| Feature | TBM Approach | Drill & Blast Method |

|---|---|---|

| Process | Continuous digging | Drill, blast, clear |

| Tunnel Length | Long tunnels | Short tunnels |

| Ground Disturbance | Minimal | More disruption |

| Tunnel Wall Finish | Smooth | Rough |

TBM Nicknames and Alternatives

People sometimes call a tunnel boring machine other names. Some nicknames are "mole" and "worm." Workers often give TBMs special names. These names can be from famous women or local heroes. For example:

- 'Victoria' worked on London’s Crossrail project.

- 'Harriet' helped build the Channel Tunnel.

- 'Alice' dug tunnels for Vancouver’s Metro.

These names make each TBM special. They help teams feel close to their machine. In some places, TBMs are named after women. This started because miners wanted Saint Barbara to protect them.

TBM Main Components

A tunnel boring machine has many important parts. These parts help it dig tunnels safely and fast. Each part works with the others to make tunneling possible.

Cutterhead

The cutterhead is at the front of the tunnel boring machine. It breaks soil and rock as it spins. The cutterhead pushes against the tunnel face. It uses disc cutters to break up the ground. These disc cutters push, roll, and cut the soil and rock. The cutterhead is made from strong steel alloys. This helps it last a long time. It works well in hard rock and soft soil.

- Disc cutters break up the rock.

- The cutterhead pushes, rolls, and cuts.

- Strong steel alloys make it tough and long-lasting.

Propulsion System

The propulsion system moves the tunnel boring machine forward. Hydraulic jacks push the machine after each digging step. The cutterhead spins and digs into the ground. Then, the propulsion system slides the machine ahead. This happens again and again. The tunnel boring machine keeps moving forward.

- The cutterhead spins and digs.

- Hydraulic jacks push the machine forward.

- Workers put concrete pieces in the tunnel.

- This cycle repeats until the tunnel is done.

Earth Pressure Balance

Earth pressure balance keeps the tunnel safe while digging. The earth pressure balance tunnel boring machine uses soil inside a special chamber for support. The system controls the pressure inside the chamber. It matches the pressure outside in the soil and water. This stops soil from falling in. It keeps the ground above safe. Mixing arms and bulkheads help keep the soil at the right pressure and texture.

- The system uses soil to support the tunnel.

- It matches pressure inside and outside.

- This stops ground movement and keeps the tunnel safe.

Conveyor and Support Systems

Conveyor systems take away the soil and rock. Belt conveyors move the material out of the tunnel fast and safely. These systems can move a lot of soil every day. They work for long tunnels and around curves. Support systems help store and move the material as the tunnel gets longer.

Conveyor systems make digging tunnels safer and faster. Modern tunnel boring machines can move over 10,000 cubic meters of soil each day.

Here is a table that shows the main parts and what they do:

| Component | Function |

|---|---|

| Cutterhead | Cuts through the ground using different cutting tools for each type of material. |

| Main drive | Makes the cutterhead spin so it can dig into the ground. |

| Conveyor system | Carries the dug-up material out of the tunnel. |

| Bearings | Helps the cutterhead spin smoothly and with less friction. |

All these parts work together to make tunneling possible. They help build tunnels faster, safer, and with less damage to the ground.

How TBM Works

Excavation Process

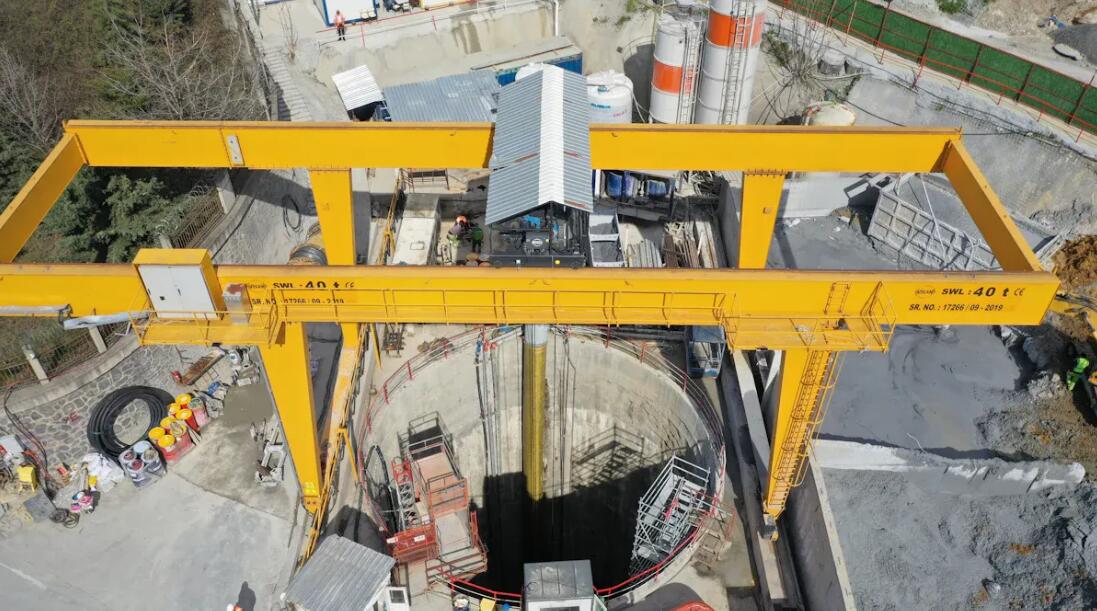

First, workers put the tunnel boring machine together at the site. This gets the machine ready to dig. When it is ready, the tbm starts to dig. The cutterhead spins and pushes into the ground. It breaks up the soil and rock. As the tbm moves, it leaves a smooth tunnel behind.

Here are the main steps for digging a tunnel:

- Assemble the TBM: Bring all the parts and build the machine at the site.

- Begin Excavation: Start the tbm and let it dig through the ground, taking out lots of dirt and rock.

- Install Tunnel Support and Lining: As the tbm moves, workers put in strong concrete pieces to hold up the tunnel.

- Complete Excavation: When the tunnel is finished, add more lining to make it safe and strong.

The tbm can dig in many types of ground, like soft dirt or hard rock. The digging speed changes with the ground. Sometimes, the machine only spends 30 to 50 percent of its time digging. Other jobs, like fixing the machine and putting in lining, also take time.

Soil and Rock Removal

When the tbm cuts into the tunnel, it breaks soil and rock into small pieces. The cutterhead at the front uses special tools to chip away the ground. Sometimes, a cone crusher inside the machine crushes big rocks into smaller ones.

Workers need to take out the broken material, called spoil, to keep the tunnel clear. The tbm uses different ways to do this:

- Conveyor belts move the spoil out of the tunnel fast and safely.

- Sometimes, screw conveyors or slurry lines carry the spoil, especially in wet or soft ground.

- For big jobs, dump trucks may take the spoil away after it leaves the tunnel.

Here is a table that shows how the tbm removes soil and rock:

| Mechanism | Description |

|---|---|

| Cutterhead | Spins and breaks up soil and rock at the tunnel face. |

| Cone Crusher | Crushes big rocks into smaller pieces for easy moving. |

| Material Transport | Moves spoil out of the tunnel with conveyor belts, screw conveyors, or slurry lines. |

Conveyor belts are used a lot in tunneling. They can move thousands of cubic meters of spoil every day. This makes digging much faster.

Tunnel Lining Installation

After the tbm digs a part of the tunnel, workers must put in tunnel lining to hold up the walls. This keeps the tunnel safe and stops the ground from moving.

There are a few ways to put in the lining:

- Put pre-cast concrete pieces right behind the tbm as it moves.

- Sometimes, steel rings or wood are used for extra support.

- Workers inject grout between the lining and tunnel wall to fill spaces and make it stronger.

- For some tunnels, a carrier pipe goes through the lining for more support.

The most common tunnel lining is made of concrete. These pieces must be strong and last a long time. Special mixes help the concrete set fast and stay strong. Protective products can be added to keep the lining safe from water and chemicals.

| Material Type | Description |

|---|---|

| Concrete Segments | Strong, pre-made pieces that make up the tunnel lining. |

| Concrete Admixtures | Make the concrete stronger and last longer. |

| Release Agents | Help take concrete pieces out of molds easily. |

| Protective Products | Protect the lining from water and chemicals in the ground. |

Putting in tunnel lining right after digging keeps the tunnel safe. This lets workers keep going with their work.

By following these steps, you can see how a tunnel boring machine makes digging tunnels safer, faster, and easier. The tbm digs, removes spoil, and puts in lining all in one smooth process.

Types of TBMs

When you look at tunnel construction, you find different types of tunnel boring machines. Each type works best in certain ground conditions. You can choose the right tbm for your project by understanding how each one operates.

Earth Pressure Balance TBM

Earth Pressure Balance TBMs work well in soft ground and areas with high water tables. You use this type when you need to keep the tunnel face stable. The machine adapts to changing ground by balancing pressure inside the cutterhead chamber. It uses the excavated soil to support the tunnel face. You often see this tbm in loose sedimentary deposits and places with lots of water.

Here are some key features:

- The machine operates in a confined mode and adapts to different ground types.

- You need products that are biodegradable and non-toxic because the machine contacts soil and water.

- Fire-resistant safety features protect workers in confined spaces.

Earth Pressure Balance TBMs help you dig safely in soft ground and keep water out of the tunnel.

Slurry TBMs

Slurry tunnel boring machine work best in water-rich sandy or gravelly soils. You use this machine when the ground has high water content or is very permeable. The tbm pumps bentonite slurry to the tunnel face. This slurry holds back water and soil, keeping the tunnel stable. Crushers and grizzly bars inside the machine break up large rocks.

Here is a table that shows how slurry TBMs operate:

| Feature | Description |

|---|---|

| Ground Conditions | Water-rich sandy and gravelly soils |

| Operation | Minimizes ground settlement and keeps face stable |

| Equipment | Crushers and grizzly bars handle boulders |

Slurry TBMs let you dig tunnels in places where water and loose soil make other methods risky.

Hard Rock TBM

Hard Rock TBMs are built for tough ground. You use this tunnel boring machine when you need to dig through solid rock. The largest hard rock TBM, called Martina, has a diameter of 15.62 meters and a length of 130 meters. These machines can handle large-scale tunnels and heavy rock.

- The Martina TBM has a diameter of 15.62 meters.

- The length of the machine reaches 130 meters.

- Hard Rock TBMs weigh up to 4,500 tons.

You choose a Hard Rock TBM for tunnels that go through mountains or deep underground rock layers.

Each type of tbm gives you the tools to dig safely and efficiently, no matter what ground you face.

TBM Advantages and Applications

Benefits Over Traditional Methods

Using a tunnel boring machine gives many big benefits over old ways. TBMs help finish tunnels faster and make the work safer. They keep the ground above steady, which is important in cities. TBMs can dig in many kinds of soil and rock. You do not have to switch machines often.

Here are some main reasons TBMs are better:

- TBMs make tunnel building more exact.

- Projects finish faster because TBMs dig all the time.

- The ground is disturbed less, so roads and buildings stay safe.

- Fewer workers are needed, so labor costs can drop a lot.

- Most work happens inside the TBM, so it is safer for workers.

- TBMs can be used in busy cities and crowded places.

- The tunnel walls are smoother, so less fixing is needed later.

TBMs keep workers safer because most digging happens inside the machine. Old ways like drill and blast are more dangerous because of drilling and using explosives. TBMs also make less noise and shaking, so people nearby are not bothered as much.

Micro tunneling machines can finish jobs about 40% faster than old ways. The average time to finish a tunnel can drop from 31.1 weeks to 18.7 weeks. This speed helps save both time and money on big jobs.

Common Uses

TBMs are used in many big building projects today. Their benefits make them the best choice for tunnels in cities and hard ground. TBMs help build tunnels for water, roads, trains, and power lines.

Here is a table that shows what TBMs are used for:

| Application Area | Description |

|---|---|

| Water Management | TBMs dig tunnels for sewers, stormwater, and water pipes. |

| Mining | TBMs make tunnels and air shafts in mines. |

| Urban Development | TBMs build subways, roads, and stations with little mess above ground. |

| Utility Tunneling | TBMs help put power, gas, and phone lines under cities. |

You can see TBMs working on famous tunnels like the Channel Tunnel, Crossrail, and the Bertha tunnel. As cities get bigger, more TBMs will be used to build safe tunnels for travel and utilities.

You now know how a tunnel boring machine helps dig tunnels safely and fast. The tbm has strong parts like the cutterhead and conveyor. These parts help make smooth tunnels. Here are some important facts:

- TBMs use new technology to build tunnels quickly and safely.

- You can use a tbm in many kinds of ground.

- TBMs help finish jobs with less noise and less mess.

Today, tunnel boring machines help build big projects in cities and mountains. This technology is changing how tunnels are made for the future.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported