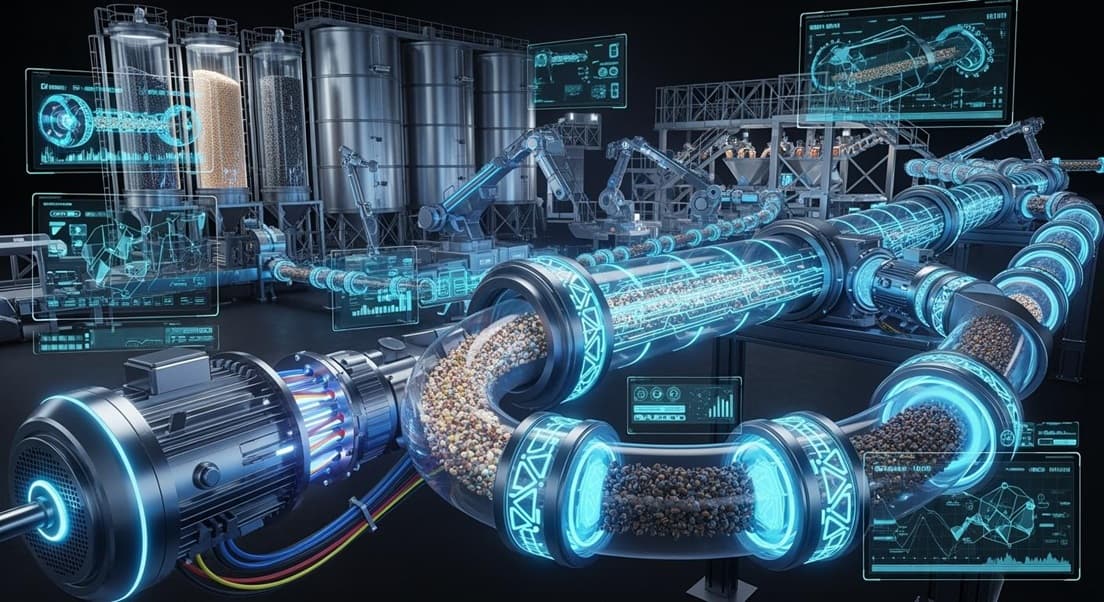

You use a advanced tube belt conveyor for seamless material when you want to keep materials safe. It keeps bulk materials away from the outside environment. This conveyor wraps into a tube shape around the load. This helps stop spills and protects the material from dust or rain. With this system, there is less waste and cleaner areas. Conveyor systems like this help move materials in a steady way. They lower labor costs and keep your work moving smoothly. You can trust this conveyor to move things with care and the same way every time.

Tube Belt Conveyor Components

Belt and Tube Formation

The tube belt conveyor is different because the belt wraps around the material. It closes up and makes a pipe shape. This keeps everything inside and stops dust from getting out. The conveyor belt system protects your product from rain and wind. The belt uses strong materials that last a long time. These materials also help save energy. Some belts use PureSteel® to make them stronger and use less power. You can move things over hills and curves because the tube belt can bend. The tube shape keeps your work area clean and safe.

Tip: The tube shape helps stop spills and keeps your product clean.

-

The belt wraps into a tube to hold materials.

-

The tube stops dust from getting out.

-

The belt bends to fit different places.

-

Strong belt materials save energy and last longer.

Hexagonal Roller Arrangement

Rollers help keep the belt in a tube shape. The conveyor uses rollers in a hexagon pattern. These rollers overlap the belt edges. This makes the belt close up into a tube. The hexagonal rollers hold the belt and keep it round. You can pick different roller sizes for your conveyor. The rollers keep the tube strong and stop it from falling apart. This setup keeps the belt straight and helps avoid spills or delays.

Note: Hexagonal rollers are important for making and keeping the tube shape.

Drive and Tension Systems

A strong drive system moves the conveyor belt. The drive pulls the belt and keeps it going at the right speed. A tension system keeps the belt tight and stops it from sagging. There are different tensioning devices you can use. Each one has good points and some limits. Here is a table to compare them:

|

Tensioning Device Type |

Advantages |

Limitations |

|---|---|---|

|

Hydraulic Automatic Tensioning |

Fast response, smooth start, less tension changes, very reliable |

Needs hydraulic system and regular care |

|

Fixed Tensioning Device |

Simple design, small size, good for tight spaces |

Cannot change tension while running |

|

Movable Tensioning Device |

Can change tension while running, fits many uses |

More parts and needs more space |

Pick the tensioning device that fits your space and care needs. The drive and tension systems work together to keep the belt moving safely.

Loading and Discharge Points

You put materials on the conveyor belt at the start. The belt closes into a tube right after you load it. This keeps the material inside and stops spills. The conveyor moves the material through the tube to the end. At the end, the belt opens and lets the material out. Special stations help stop product backup and keep things moving. The frame holds the belt and keeps it straight. If the frame is weak, the belt can get crooked or break. Good loading and discharge points help you avoid delays and spills.

-

Loading points put material on the belt.

-

The belt closes into a tube to hold the material.

-

Discharge points open the belt and let the product out.

-

Special stations stop product backup.

-

A strong frame keeps the belt straight and stops problems.

Reminder: Good loading and discharge points help move materials well and keep your conveyor working.

All the parts of the long distance curved tube belt conveyor work together. They make a safe and closed way to move bulk materials. These parts help protect your product and keep your work area clean. The conveyor is flexible and reliable for many jobs. If you look at tube belt conveyors and cable or chain conveyors, you will see the tube design gives better protection and less spillage.

How Tube Conveyor Systems Work

Material Loading and Enclosure

When you use a tube conveyor system, you start at the loading spot. You put bulk materials onto the conveyor belt. The belt is flat at first, so loading is easy. As the belt moves, rollers help wrap it around the material. The belt turns into a closed tube shape. This tube keeps the material inside and away from outside air.

The closed tube design protects your material from dust and rain. You do not have to worry about powders blowing away or water ruining your product. The tube shape also stops spills as the conveyor moves. This means you keep more product and your work area stays clean.

Tip: The tube shape keeps your material safe from dirt and spills. You get better results, especially with fine or sensitive materials.

Conveying Process

After the material is inside the tube, the conveyor carries it along the path. Rollers keep the belt round, so the material stays inside. You can move materials far, around curves, and up or down hills. The tube conveyor works well when you need to protect the material or avoid messes.

Tube conveyor systems move materials at steady speeds. The closed tube keeps the material safe from wind, rain, and dust. This is important for chemicals, food, or other products that must stay clean. The tube conveyor also helps you avoid losing material. You do not have to clean up spills or worry about waste.

Here is a table that shows how conveyor systems handle different speeds and amounts:

|

Conveyor Type |

Speed (m/s) |

Capacity (TPD) |

Notes |

|---|---|---|---|

|

Incline Conveyor |

4.26 |

10,000 |

Faster speed keeps the same load and area. |

|

Original Design |

3.31 |

6,800 |

First capacity before changes. |

|

Required Increase |

4.19 |

1,400 |

Changed to meet new needs with a 25% speed boost. |

You can see tube conveyor systems move lots of material quickly and safely. The tube shape helps keep the material inside, even at high speeds.

Unloading and Belt Flattening

When the material gets to the end, the belt opens up. Special rollers help the belt go flat again. The tube opens, and the material drops off at the discharge spot. You can control where and how the material leaves the conveyor. This helps you avoid piles or backups.

The tube conveyor system makes sure almost all the material gets to the end. The closed tube protects the material until the last moment. You do not have to worry about dust or spills at the end because the system opens only where you want.

Note: The tube conveyor system lets you control loading and unloading. You keep your work area clean and your product safe.

Advantages of Tube Belt Conveyors

Environmental Protection

Using a tube belt conveyor helps protect the environment. The closed design keeps dust and small particles inside. This stops coal dust and other materials from getting into the air. Closed-trough conveyor systems can save a lot of dust each year. The conveyor belt uses a special rubber compound. This helps you use less energy, up to 25% less. Cleaner air and lower energy use help your company follow the rules. You also make your worksite safer and healthier for everyone.

-

The tube conveyor system keeps dust from escaping.

-

Special belt materials help you use less energy.

-

You help meet environmental rules and make air cleaner.

Reduced Spillage and Maintenance

A tube conveyor system helps you avoid messy spills. The tube shape keeps all the material inside, even on curves or hills. You do not need to clean up as much, so you save time and money. Less spillage means less waste and fewer repairs. You also spend less time on maintenance because the conveyor stays cleaner. Regular checks and good training help you find problems early. This keeps your conveyor working well and helps you follow safety rules.

Tip: Check your conveyor often and train workers to keep it safe.

Flexibility and Routing

A tube conveyor system gives you more choices. You can change the layout if you need to move things. The conveyor can bend, go up, or go down to fit your space. You can make the system bigger or smaller as needed. You can also change the height and angle to make loading and unloading easier. The tube conveyor system can connect with other conveyors for smooth work. This flexibility helps you move many kinds of products and keeps your work going.

|

Condition |

Effect on Conveyor Belt |

|---|---|

|

High Humidity |

Rubber can get bigger or weaker. Mold can grow. |

|

High Temperature |

Belt may wear out faster or get soft. Check it often. |

Note: Pick belts that resist moisture if you work in wet places.

Applications and Alternatives

Industrial Uses of Tube Belt Conveyors

Tube belt tripper conveyors for iron ore and coal are used in many industries. These systems help move bulk materials safely. In mining, they carry large amounts of ore or coal. Metal processing plants use them for heavy materials. Chemical refineries use them to move sensitive products without mixing. Food factories use them to keep food clean and safe. Construction sites use them to move sand, gravel, and other building stuff.

Here is a table that shows how different industries use tube belt conveyor systems:

|

Industry |

Benefits |

|---|---|

|

Manufacturing |

Raises productivity, improves accuracy, lowers labor costs, makes work safer. |

|

Food Processing |

Makes moving things easier, keeps products and workers safe. |

|

Warehousing |

Helps work go faster, supports machines, makes work smoother. |

-

Mining: Moves lots of material.

-

Metal Processing: Needed for daily work.

-

Chemical Refinery: Moves materials safely.

-

Food Production: Keeps things safe and fast.

-

Construction: Moves heavy stuff easily.

Tip: Use tube conveyor systems when you need to keep materials safe from dust, water, or spills.

Pipe Conveyor vs. Tube Belt Conveyor

You may wonder how a pipe conveyor is different from a tube belt conveyor. Both systems move materials inside a closed space, but they are not the same. A tube belt conveyor is heavier and costs more than a pipe conveyor. If you want something lighter and cheaper, pick a pipe conveyor. Tube belt conveyors are stronger and protect materials better, which helps in hard jobs.

Here is a table to compare them:

|

Conveyor Type |

Weight Comparison |

Cost Comparison |

|---|---|---|

|

Tube Belt Conveyor |

1.6 times heavier |

1.44 times more |

|

Pipe Conveyor |

Lighter |

Less expensive |

Pick the conveyor that matches your money and job needs. Pipe conveyors are good for lighter loads and lower prices. Tube belt conveyors are better for tough jobs that need more strength.

Tubular Drag Conveyors Overview

Tubular drag conveyors are another way to move materials. These systems are good when you need to be gentle. Tubular drag conveyors pull materials through a tube with a chain or cable. You can move powders, grains, or breakable things without hurting them. These systems work well in food, chemical, and medicine factories. Tubular drag conveyors make less dust and fewer spills. They also fit into small spaces because they can bend.

Note: Tubular drag conveyors are good for moving soft or breakable materials. Use them when you need a clean and gentle way to move things.

There are many ways to move materials. Tube belt conveyors give strong protection and work in hard places. Pipe conveyors are lighter and cost less. Tubular drag conveyors are gentle for fragile products. Think about what you need and choose the best conveyor for your job.

Choosing and Installing Tube Belt Conveyors

Material and Capacity Considerations

When you choose a tube belt conveyor, you need to think about your material and how much you want to move. Start by looking at the product’s weight, size, and texture. Some materials have moisture, oil, or even acid. These can affect how the conveyor works. You should also know if you are moving raw materials or finished goods. The stage of production matters. Check the temperature and moisture in your work area. These can change how long your conveyor lasts. Think about the direction your product will travel. Some routes have curves or go up and down.

-

Look at the weight, size, and texture of your material.

-

Decide if you need to move raw or finished products.

-

Check the temperature and moisture in your space.

-

Plan the direction and path for your conveyor.

If you compare tube belt conveyors with pipe conveyor or tubular drag conveyors, you will see each one fits different needs. Pipe conveyor works well for lighter loads. Tubular drag conveyors are gentle with fragile products.

Layout and Environmental Factors

Your layout and environment play a big part in how your conveyor systems work. Dust, moisture, and chemicals can cause problems. Use the table below to see how these factors affect your conveyor:

|

Environmental Factor |

Impact on Conveyor Systems |

|---|---|

|

Dust |

Increases wear and tear, needs more cleaning. |

|

Moisture |

Can cause mechanical issues, needs special design. |

|

Chemical Exposure |

May need explosion-proof parts and special materials. |

You should plan your conveyor route to avoid sharp turns and steep slopes. If you use a pipe conveyor or tubular drag conveyors, you can handle tight spaces and curves better. Always match your conveyor systems to your work area for the best results.

Maintenance and Safety Tips

Keeping your conveyor safe and working well takes regular care. You should check belt tension often. Use sensors to watch for problems. Look at splices, pulleys, and rollers for damage. Remove any debris or buildup. Lubricate moving parts to keep everything running smoothly.

-

Check belt tension and look for wear.

-

Use sensors to spot problems early.

-

Inspect splices, pulleys, and rollers.

-

Remove debris and add lubricant as needed.

-

Watch for uneven wear and frayed edges.

-

Keep records of all checks and repairs.

Stay safe by guarding moving parts and training workers. Make sure everyone wears fitted clothes and no jewelry. Keep the area clean and well-lit to prevent slips and falls. Follow OSHA and ASME rules for all conveyor systems. During installation, watch for belt twisting or slippage. Make sure all parts line up and rollers turn freely. If you use a pipe conveyor or tubular drag conveyors, check for special needs during setup.

Tip: Regular checks and good training help you avoid accidents and keep your conveyor running longer.

You have learned that a tube belt conveyor is safe and flexible. It keeps your product inside the tube. This protects it from dust and rain. Many people pick tube belt conveyors instead of pipe conveyors. The table below explains why:

|

Advantage |

Description |

|---|---|

|

Material Containment |

Keeps out dirt and shields from bad weather. |

|

Flexible Layout |

Works in small spaces and turns easily. |

|

High Inclination |

Moves things up steep hills. |

|

Two-way Transport |

Can move materials forward and backward. |

|

Space Efficiency |

Needs less room than a pipe conveyor. |

Knowing about these systems helps you handle bulk materials better. If you want to add or change a conveyor, ask experts for help.

Tip: Smart sensors and AI can help your pipe conveyor work better and safer.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported