You can find a few main types of TBM, including hard rock, earth pressure balance (EPB), and slurry machines. Each type of TBM is designed for specific ground conditions. Hard rock TBMs are best suited for solid rock, while earth pressure balance and slurry TBMs excel in soft ground, making them popular in urban environments. Selecting the appropriate tunnel boring machine is crucial for ensuring safety and efficiency. Many city projects utilize EPB and slurry TBMs, as these machines effectively manage soil movement and settlement. Companies like NHI manufacture advanced tunnel boring equipment tailored for these applications. Using the right types of TBM for your soil conditions significantly contributes to the success of your project.

Types of Tunnel Boring Machines

When you begin a tunneling job, you must pick a tunnel boring machine. Each kind works best in certain ground types. Let’s learn about the different tunnel boring machines and where they fit.

Hard Rock TBM

Hard rock tunnel boring machines are made for strong rock. These machines have a tough cutting head with disc or roller cutters. The cutters break the rock into pieces. Here is a table that shows their main features and how they work:

| Feature/Principle | Description |

|---|---|

| Rock Chipping vs. Grinding | Chips rock quickly for faster digging. |

| Cutting Tools | Uses disc cutters for soft rocks and roller cutters for hard rocks. |

| Excavation Mechanism | Steel cutting head with cutters breaks the rock. |

| Hydraulic Jacks | Four jacks push the head forward to make boring easier. |

| Operational Efficiency | Boring takes 30-50% of the time; the rest is for support and fixing. |

| Advantages | Less shaking, faster digging, lower cost, and safer than blasting. |

| Environmental Impact | Makes less noise and fewer fumes, which helps in cities. |

Use hard rock tbms when you have strong rocks with good structure. These machines work best when the rock is brittle and has a strength above 150 MPa. NHI makes main beam tbm and single shield tbm for these hard jobs.

Earth Pressure Balance (EPB) TBM

Earth pressure balance tbm is common for soft ground. You use these machines in clay, silt, or mixed ground, mostly in cities. The main parts are:

- Cutterhead: Cuts soil at the tunnel front.

- Excavation Chamber: Holds soil and keeps pressure steady.

- Screw Conveyor: Moves soil out and controls speed.

- Shield: Protects the tunnel and machine.

- Grouting System: Fills gaps between tunnel lining and ground.

- Segment Erector: Puts in concrete lining pieces.

- Propulsion System: Pushes the machine forward.

- Control Cabin: Lets you watch and control all systems.

EPB tunnel boring machines help control pressure and stop ground sinking. They are great for soft ground tbms in cities. NHI makes advanced earth pressure balance models for these jobs.

| Equipment Type | Primary Function | Ground Conditions | Key Benefits |

|---|---|---|---|

| Earth Pressure Balance TBM | Soft ground digging | Clay, silt, mixed ground | Controls pressure, stops sinking |

Slurry TBM

Slurry tunnel boring machines are also good for soft ground tbms, especially in wet or mixed soils. These machines use bentonite slurry to hold up the tunnel face and move soil out. Here are the main parts:

| Component | Description |

|---|---|

| Cutter head | Has teeth, discs, or blades |

| Protective shield | Holds up the tunnel while digging |

| Thrust jacks | Push the TBM forward |

| Slurry system | Mixes and separates soil from the dug material |

A slurry shield tbm keeps the tunnel face safe by mixing soil with slurry and pumping it out. Use this machine in places with lots of water or loose, sandy soil. Data from real jobs shows slurry shield tbm can balance forces and keep tunnels safe in tough spots. NHI also makes slurry tunnel boring machines for these places.

Open Shield TBM

Open shield tunnel boring machines have a special design. They use air pressure at the tunnel face, so the front is open to air. Use open shield tunnel boring machines in places where the ground is strong and does not need extra help. These machines are also called open face type tbm. They are simple and cheap for short tunnels or strong ground.

| Type of TBM | Operational Mode | Suitable Conditions |

|---|---|---|

| Open Shield TBM | Air pressure at face | Strong ground, some rocks |

NHI makes open shield tunnel boring machines for jobs that need a simple way.

Double Shield TBM

Double shield tbm mixes features of open and closed shield machines. You can use these machines in many ground types, from hard rock to mixed soils. The double shield design lets you dig and put in tunnel lining at the same time. This means faster work and safer crews.

- Works in many ground types

- Keeps workers safe

- Puts in tunnel lining while digging

- Gives support and lowers surface problems

NHI has double shield tbm models for hard jobs that need strong and flexible machines.

When you pick a tunnel boring machine, match it to your ground type. NHI is a trusted company that makes many kinds of tbm for jobs everywhere. If you know the strengths of each type, you can choose the best tunnel drilling machine for your needs.

TBM Mechanisms

How Hard Rock TBMs Work

You use a hard rock TBM when you need to dig through solid rock. The machine pushes forward with strong hydraulic jacks. The cutter head rotates and presses against the rock face. Here’s how it breaks and removes rock:

- Normal pushing force: The TBM applies direct pressure to the rock, helping the cutters dig in.

- Tangential rolling cutting force: The cutters roll and shear the rock, making the process efficient.

- Lateral force: The rotation of the cutter head creates a small sideways force, helping break up the rock.

This method lets you tunnel quickly and safely in hard, brittle rock. NHI’s hard rock TBMs use these forces to keep your project moving forward.

How EPB TBMs Work

Earth Pressure Balance (EPB) TBMs help you dig in soft ground, like clay or silt. The machine keeps the tunnel face stable by balancing the pressure inside the chamber. You can see the main mechanisms in the table below:

| Mechanism | Description |

|---|---|

| Pressure Control | Adjusts chamber pressure to match earth and water pressure. |

| Soil Support Medium | Uses excavated soil to support the tunnel face. |

| Soil Conditioning | Adds agents to make the soil easier to handle and control. |

| Segmental Lining | Installs concrete segments for instant tunnel support. |

| Monitoring and Control | Tracks pressure and torque for safe, steady progress. |

With these features, EPB TBMs stop ground settlement and keep your tunnel safe, especially in cities.

How Slurry TBMs Work

Slurry TBMs work best in water-rich or loose soils. The machine mixes the soil with slurry, which supports the tunnel face and carries the soil away. You often use foam agents, dispersants, and bentonite to improve the flow and stability of the mixture. This helps reduce friction and keeps the tunnel face safe. Slurry TBMs also use flushing systems and extra slurry circulation to prevent clogging and downtime. You get a smooth, safe tunnel even in tricky ground.

How Open Shield and Double Shield TBMs Work

Open shield TBMs suit strong ground where you do not need much support. Double shield TBMs combine features for both hard and mixed ground. These machines use several smart strategies:

| Strategy | Description |

|---|---|

| Stepped Shield | Tapered design helps the TBM move through tight spots. |

| Probe Drilling | Lets you check the ground ahead and add grout if needed. |

| Shield Lubrication | Ports allow for lubrication to help the TBM move smoothly. |

| Forepoling | Drills holes above the TBM to insert poles for extra ground support. |

These strategies help you handle changing ground conditions and keep your project on track. NHI offers both open shield and double shield TBMs for these needs.

Tunnel Boring Machine Applications

Hard Rock Environments

Tunnel boring machines work deep underground in hard rock. These machines dig through solid rock and keep workers safe. Many big projects use hard rock TBMs because they are strong. Here are some examples from real jobs:

| Project Name | Description |

|---|---|

| East Side Access CQ31 Queens Tunnels | A big tunnel job in New York City using hard rock TBMs. |

| Seymour Capilano Twin Tunnels | A project in Canada that used hard rock tunneling methods. |

| LADWP’s Upper Reach—Unit 7 | Los Angeles Department of Water and Power used advanced TBM machines. |

| LA Metro’s Purple Line Extension 2 and 3 Tunnels | A large transit job in Los Angeles built with hard rock TBMs. |

You need to pick the right TBM for the rock type. Hard rock TBMs work best in strong ground. They help finish big projects safely.

Soft Ground and Urban Tunnels

Building tunnels in soft ground or busy cities is hard. Earth Pressure Balance TBMs are made for these places. These machines keep the tunnel face steady and stop the ground from moving. This is important when buildings and roads are close. EPB TBMs control pressure inside the cutterhead. This stops the tunnel from collapsing and keeps the ground from sinking. You can use EPB TBMs for subway tunnels, utility tunnels, and other city jobs.

Tip: Always pick a tunnel boring machine that fits the soil and water in your city project. This keeps buildings safe and helps your work go well.

Water-Bearing and Mixed Soils

Sometimes you dig through ground with lots of water or mixed soils. Slurry TBMs are best for these jobs. These machines use slurry to hold up the tunnel face and move soil out. You can use slurry TBMs for tunnels under rivers, near coasts, or in loose sand and gravel. This keeps water out and stops the soil from falling in while digging.

Large-Scale and Long-Distance Projects

Big and long tunnel jobs need strong tunnel boring machines. Here are some types you can use:

- Hard Rock TBMs: Use these for solid rock. They are tough and work fast.

- Soft Rock TBMs: Pick these for softer ground. They are flexible.

- Herrenknecht TBMs: Choose these for tricky city projects. They have special designs.

- Prufrock TBMs: Use these for quick and cheap jobs. They help you finish faster.

Always match the tunnel boring machine to your project and ground. This keeps everyone safe and helps your project succeed.

TBM Selection Factors

Ground and Soil Conditions

When picking a tunnel boring machine, you need to study the ground. The soil and rock type changes how the machine works. Here are some things to think about:

- Geological features help you choose the right TBM.

- Ground type affects how much force and turning power you need.

- You should change digging speed for each soil type.

- Guessing how the ground moves helps keep tunnels safe.

If you skip these steps, you might get ground sinking or cracks in the tunnel. Always check the ground before you start digging.

Project Requirements

Project needs matter when choosing your TBM. Think about tunnel size and path. Big tunnels need full-face TBMs to stop sinking. Small tunnels use segmental TBMs for better control. Match the TBM to your tunnel’s shape and size. This helps you finish safely and on time.

Environmental and Cost Considerations

You should also think about the environment and cost. The table below shows important things to check:

| Consideration Type | Details |

|---|---|

| Carbon Footprint | Check carbon emissions during building and running. |

| Material Usage | Making TBMs uses lots of materials, which affects cost and nature. |

| Energy Consumption | TBMs need power, which adds to environmental impact. |

| Excavation Method | Picking drill and blast or TBM changes time, cost, and nature issues. |

Tip: Always plan for safety and future costs. Good planning helps you avoid mistakes like missing ground movement or forgetting joint design.

When picking tunnel boring machines, balance ground, project needs, and nature impact. Brands like NHI have many choices to fit your job and keep it safe.

Advances in Tunnel Boring Machines

Automation and Monitoring

Tunnel boring machines work differently now. Automation and digital tools are important. Sensors collect data all the time. AI looks at this data to make things better. Robots do dangerous jobs to keep people safe. Check the table below to see these changes:

| Innovation | Description |

|---|---|

| AI-Driven Innovations | AI checks sensor data to find problems and help work faster. |

| Robotics Integration | Robots do risky jobs so people stay safe. |

| Real-Time Monitoring | Sensors give quick updates for fast choices. |

| Predictive Algorithms | Smart systems keep work steady and make digging faster. |

Automation helps with hard ground and keeps projects on track.

Sustainability Improvements

New ways and materials make tunneling better for nature. Many projects use water from digging to control dust or refill water underground. Some tunnel boring machines use heat from the ground for buildings. Dirt from tunnels is used nearby, so there are fewer trucks and less pollution. Here are more ways to help the environment:

- Add fly ash or slag to concrete.

- Dig tunnels at an angle to move dirt with gravity.

- Use green energy for building.

- Pick biodiesel for cleaner fuel.

- Plant native plants after digging to fix habitats.

Tip: Green tunneling helps nature and saves money later.

Performance Enhancements

Tunneling is faster and more flexible now. Some tunnel boring machines have thousands of sensors to react quickly. Some machines can change size inside the tunnel for different jobs. Autonomous TBMs need little help from people and work faster. Digging in soft ground can go on without stopping much. New plasma and hot gas tools may make digging even quicker.

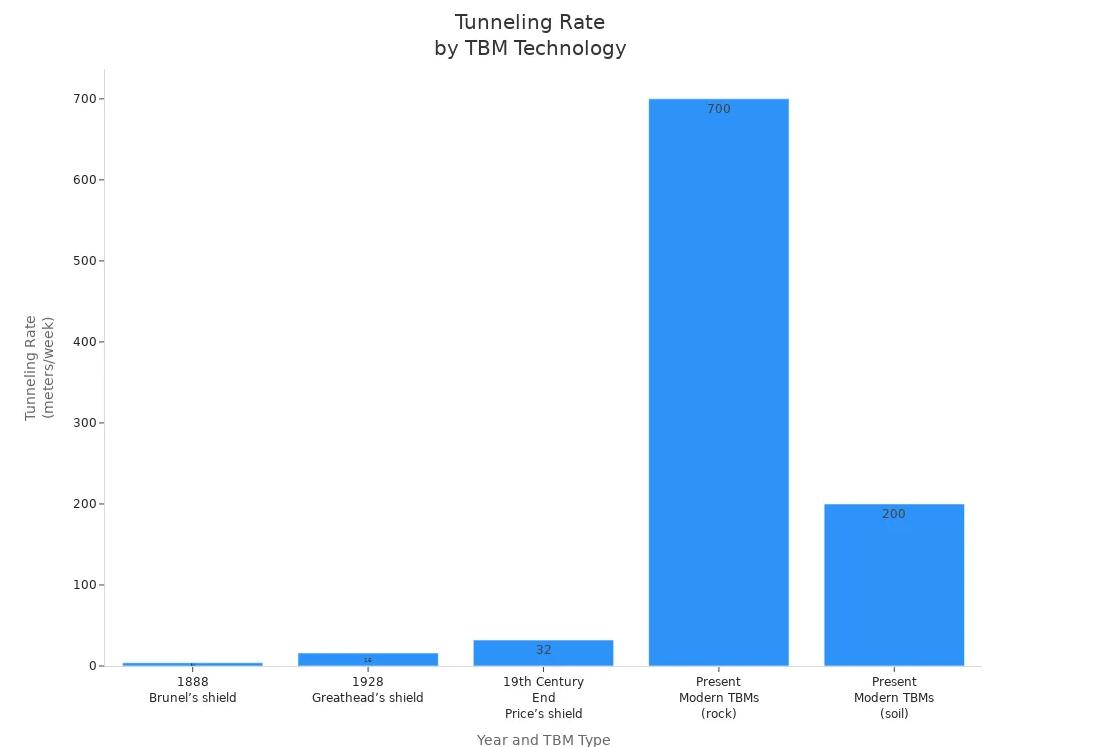

Today, you can dig up to 700 meters each week in rock and 200 meters each week in soil. These new tools help finish jobs faster and lower risks.

Each tunnel boring machine works best in certain ground and jobs. The table below shows how they are different:

| Type of TBM | Description |

|---|---|

| Gripper TBM | Good for hard rock, uses roller disc cutters, pushes on tunnel walls. |

| Earth Pressure Balance TBM | Handles loose ground, uses soil to hold up the face, checks pressure with sensors. |

| Slurry TBM | Works in sandy or wet soils, holds up the face with slurry, needs careful watching. |

| Double-Shield TBM | Fast in hard rock, uses two shields for safe and quick digging. |

Picking the right TBM keeps everyone safe and helps your project go well. Always check the ground and talk to experts for tricky tunnels. Experts can help you find almost all risks, making your project safer and more dependable.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported