When you pick tube belt conveyors for bulk material handling, you get many clear benefits. Many people think these systems are easy to use because the conveyor belt works like regular designs. The enclosed tube keeps your products safe from dirt and stops material from falling out. You can make flexible layouts with sharp turns and steep angles, even up to 30°. This helps you work in small spaces. Some people believe these conveyors cannot handle tricky routes or need lots of cleaning, but you will see they work well and are simple to take care of. Tube belt conveyors for mining equipment make moving materials safer, cleaner, and save money.

What Are Tube Belt Conveyors?

Design and Operation

NHI's industrial tube belt conveyors are used in many places. They help move lots of materials. These systems have a special design. The belt starts flat. Then it turns into a U-shape. Next, it becomes a closed tube. The tube keeps materials inside. It stops dirt and water from getting in.

The main parts work together. They help the conveyor run well. Here is a table that shows the important parts and what they do:

|

Structural Component |

Description |

|---|---|

|

Driving device |

Powers the conveyor system. |

|

Driving roller |

Moves the conveyor belt. |

|

Tailstock |

Supports the end of the belt. |

|

Screw tensioning device |

Keeps the belt tight. |

|

Redirecting roller |

Changes the belt’s direction. |

|

Transition frame |

Connects sections of the conveyor. |

|

Conveyor belt |

Carries the materials. |

|

Bracket |

Supports the system. |

|

Hexagonal idler group |

Rolls the belt into a tube shape. |

|

Horizontal belt turning device |

Turns the belt horizontally. |

|

Intermediate racks |

Supports the belt at intervals. |

|

Towers |

Gives vertical support. |

|

Tubular conveyor belt |

Forms a tube for airtight transport. |

|

Material flow process |

Material enters at the tail, changes shape, and moves through the tube. |

New tube conveyor systems use light materials. PVC and nylon are common. These materials are easy to clean. They help stop bacteria from growing. Some systems use smart sensors. Automation makes them safer and faster.

Key Differences from Other Conveyors

Tube belt conveyors are different from regular ones. The tube is closed. It keeps materials safe. It stops spills. Regular conveyors are open. Materials can fall off. They can get dirty. Tube conveyors can turn sharp corners. They can go up steep hills. You can make tricky routes to fit your space.

Here is a table that compares tube belt conveyors with regular belt conveyors:

|

Feature |

Tube Belt Conveyors |

Conventional Belt Conveyors |

|---|---|---|

|

Design |

Enclosed tube shape |

Open belt |

|

Spillage Prevention |

Yes |

No |

|

Routing Options |

Complex, steep inclines |

Limited |

|

Durability |

High |

Lower |

|

Efficiency |

Enhanced |

Standard |

Tube conveyors use new technology. Many use recycled materials. Some use solar power. These features save energy. They help the environment. Tube belt conveyors are safe. They are clean. They are flexible for moving lots of materials.

Product Protection and Material Integrity

Gentle Handling and Reduced Breakage

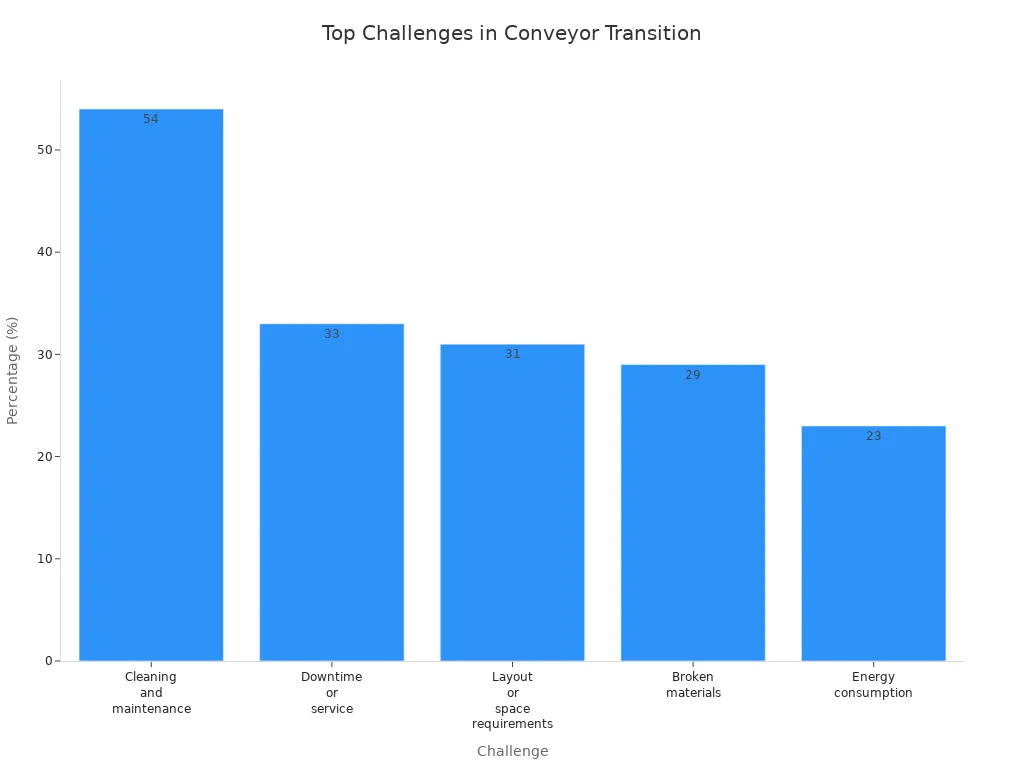

It is important to keep products safe while moving them. Heavy duty tube belt conveyors help protect materials. Their design lets materials move gently. This means less chance of damage. Many places have trouble with broken items. Tube belt conveyors lower this risk. They have fewer places where materials can hit or rub. This helps stop things from breaking.

Here is a table that shows how tube belt conveyors help keep materials safe:

|

Evidence Description |

Impact on Breakage |

|---|---|

|

Tube conveyor systems minimize contact points and impacts |

There is almost no chance for things to break |

|

29% of industrial facilities identify material breakage as a top challenge |

Shows why stopping breakage is important |

|

Tubular conveyors operate at low speeds |

Less shaking means less chance of breaking |

Tube belt conveyors protect materials at every step. You can trust your products will stay in good shape. Even fragile items arrive safely.

Enclosed Design for Clean Transport

Keeping products clean is also very important. Tube belt conveyors have a closed design. This keeps dust and dirt out. It is needed in places like food and medicine factories. These places have strict health rules. The closed tube can even use a vacuum. This makes the system cleaner.

Tip: Using an enclosed conveyor helps you follow rules and keeps workers safe.

The enclosed design helps keep materials clean in many ways:

|

Feature |

Description |

|---|---|

|

Enclosed Transport System |

The belt forms a closed pipe to keep materials inside and stop spills. |

|

Reduced Environmental Impact |

This design cuts down on dust and spills, which helps the environment. |

|

Advantage |

Explanation |

|---|---|

|

Zero Spillage |

The sealed tubes stop spills and make work safer. |

|

Essential Dust Control |

The design blocks dust, helping you follow safety rules. |

|

Benefit |

Impact |

|---|---|

|

Cleaner Working Environment |

The closed design lowers dust and noise, making work safer. |

|

Contamination Prevention |

Keeping materials inside protects the area from getting dirty. |

Tube belt conveyors keep outside dirt away from your products. Your materials stay clean and safe from start to finish. This helps your business do better and makes customers happy.

Efficiency and Versatility of Tube Belt Conveyors

Handling Turns and Inclines

You need machines that fit your workspace. Tube belt conveyors are flexible. They move materials around sharp corners. They work in tight spaces. The belt forms a tube. It can twist and turn. Nothing spills out. This design helps you use space better. Your work stays smooth.

Many conveyors have trouble with steep slopes. Tube belt conveyors fix this problem. They work on slopes from 30° to 90°. Regular belt conveyors cannot do this. You can move things up and down easily. You do not need extra machines. Your process gets faster and safer.

Tip: Tube belt conveyors help you save money. They work well in small spaces and on steep ramps.

Here is a table that shows how tube belt conveyors compare with other equipment for turns and slopes:

|

Feature |

Tube Belt Conveyors |

Conventional Belt Conveyors |

Other Equipment (e.g., bucket elevators) |

|---|---|---|---|

|

Sharp Turns |

Yes |

Limited |

No |

|

Steep Inclines |

30°–90° |

Up to 20° |

Yes |

|

Spillage Prevention |

Excellent |

Poor |

Good |

|

Space Efficiency |

High |

Medium |

Low |

Bidirectional and Long-Distance Transport

You want machines that move materials both ways. Tube belt conveyors do this. You can reverse the belt. This sends things back and forth. It saves time and work. You do not need extra systems.

Tube belt conveyors work for long distances. They move lots of material across buildings. The tube keeps things safe from weather and dirt. You get good results all year.

Tube belt conveyors use less energy than old roller conveyors. For example:

-

The VecoBelt series uses half the electricity of older machines.

-

You spend less money on power.

Tube belt conveyors may move less material than open belts. But you get big benefits:

-

You stop spills and keep things safe.

-

You avoid losing material from dust and dirt.

-

You can change the belt width, speed, and design.

Note: Picking the right machine helps you balance speed, safety, and energy use. Tube belt conveyors give you safe, clean, and energy-saving transport.

Here are the main benefits for long-distance and two-way transport:

-

Move things far with fewer stops.

-

Use less energy and save money.

-

Keep products safe from spills and outside dangers.

-

Use one machine for both ways, making work easier.

Tube belt conveyors help you do more with your equipment. You can handle tough routes, steep slopes, and long trips. Your materials stay safe and your costs stay low.

Cost, Maintenance, and Environmental Benefits

Lower Operational Costs

Tube belt conveyors help you spend less money. These systems use less energy. You do not need many workers. You save money every time you move things. Tube belt conveyors cost much less than trucks. Look at the table to compare costs:

|

Transport Method |

Average Operational Cost per Ton |

|---|---|

|

Tube Belt Conveyors |

0.20 Euros |

|

Truck Transport |

3.00 Euros |

Tube belt conveyors help you save money over time. They move materials by themselves. This means fewer mistakes and faster work. You pay less for workers and energy. Safety gets better, so there are fewer accidents and less time lost.

Tip: Saving money and having safer work helps your business grow.

Reduced Maintenance Needs

You want your machines to work well. Tube belt conveyors need regular care. You can keep problems small with good planning. Most companies check their conveyors once or twice a year. How much you pay depends on your plan.

-

Regular care stops big problems.

-

Service happens at set times each year.

-

Costs change with your maintenance plan.

Some problems are belt slipping, rollers getting stuck, and blockages. Cleaning and design can make care harder. You can use smart ideas to stop long delays:

-

Check your conveyor often.

-

Use sensors to find problems early.

-

Pick the right belt for your job.

-

Teach your team how to do maintenance.

Environmental Sustainability

Tube belt conveyors help protect the earth. Many systems have top awards for being green. Here are some examples:

|

Certification |

Description |

|---|---|

|

ISO 14001 |

International standard for using fewer resources and recycling. |

|

Rating Agency |

Rating |

Description |

|---|---|---|

|

Sustainalytics |

Low Risk |

Shows low risk for the environment. |

|

MSCI |

AAA |

Highest score for caring about the environment. |

|

CDP |

A- (Climate Change), B (Water Security) |

Known for climate and water safety work. |

Tube belt conveyors help you follow safety rules. They make your workplace safer and help you avoid fines.

|

Key Points |

Description |

|---|---|

|

Workplace Safety |

Makes work safer and lowers risks. |

|

Prevents Injuries |

Helps stop injuries and plant shutdowns. |

|

Regulatory Compliance |

Meets safety rules and lowers problems. |

You can trust tube belt conveyors to help your business and the planet.

Comparison with Other Conveying Systems

Tube Belt Conveyors vs. Traditional Belt Conveyors

You might wonder how tube belt conveyors compare to traditional belt conveyors. Tube belt conveyors have an enclosed design. This keeps materials safe and clean. Traditional belt conveyors leave materials open. This means more spills and dust can happen.

Look at this table. It shows how tube belt conveyors work better than traditional ones:

|

Criteria |

Pipe Conveyor Belt Systems |

Traditional Conveyors |

|---|---|---|

|

Material Spillage |

Zero spillage due to enclosed system |

Higher risk of spillage, especially with fine or sticky material |

|

Dust Control |

Excellent – prevents dust escape entirely |

Requires additional dust suppression systems |

|

Environmental Impact |

Lower – prevents leakage and reduces carbon footprint |

Higher – may require more energy and cleaning infrastructure |

Tube belt conveyors help you clean less. You do not need special dust control machines. You also use less energy. This saves money and helps the earth.

Switching to tube belt conveyors can be hard. Cleaning and fixing them can be tricky. You might have downtime and need to change your layout. Here is a chart that shows common problems:

Tip: Make a good plan before you switch. Teach your team and do regular checks to keep things working well.

Tube Belt Conveyors vs. Chain and Truck Transport

You might use trucks or chain conveyors to move materials. Tube belt conveyors are safer and cleaner. Trucks can have more accidents. Chain conveyors need more workers and can be loud.

See this table. It shows safety rates:

|

Mode of Transport |

Safety Incident Rate |

Notes |

|---|---|---|

|

Conveyors |

Lower risk |

Needs fewer workers and works all the time with less access during use |

|

Trucks |

Higher risk |

Uses heavy machines, with 75% of struck-by deaths at worksites caused by trucks or cranes |

Tube belt conveyors help lower injuries at work. You also have less downtime. Your materials stay safe from weather and spills. You spend less on fixing things and insurance.

Note: Picking tube belt conveyors helps you make your workplace safer, cleaner, and more efficient.

Tube belt conveyors help you move materials in a cleaner way. They make your work safer and more efficient. You can stop problems like spills and broken products. These conveyors work well in places with tricky layouts. When you plan your system, think about what you are moving. Look at how much space you have. Remember to check how you will clean and fix the conveyor. Safety is important too. Experts say you should pick the best belt material. Make sure the belt stays straight. Design your system so you can reach it easily. Try to plan how your materials will move. Use smart controls to help your system work better. Always think about what you need. Talk to people who know a lot before you choose.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported