Tube belt conveyors are the best for moving lots of materials. You get many important benefits:

-

The closed design keeps dust and spills inside. This helps protect the environment.

-

Turning ability lets you handle sharp turns and steep hills.

-

You can move materials both ways with bidirectional transport.

-

Cost efficiency helps you save money on repairs and running costs.

-

High elevation ability makes it easy to move things up steep slopes.

This system helps you make your facility safer, more efficient, and flexible.

Key Takeaways

-

Tube belt conveyors stop dust and spills from escaping. This helps protect nature and makes cleaning easier. These conveyors can turn sharply and go up steep hills. They work well for many types of jobs. Tube belt conveyors help keep materials from breaking. Fragile items stay safe while moving. These conveyors need less fixing and work well all the time. This saves money over the years. Tube belt conveyors are a good choice. The closed design makes work safer. It lowers the chance of getting hurt. It also helps follow rules for the environment.

Tube Belt Conveyors and Material Protection

Preventing Spillage and Contamination

It is important to keep your facility clean and safe. Tube belt conveyors help by keeping materials inside while moving them. The belt closes up like a pipe, so spills do not happen. Dust stays inside and does not get out. This design keeps your bulk material safe from outside germs or dirt. You also lose less product because it does not spill.

Using tube belt conveyors helps keep the environment clean and safe. Materials stay inside the conveyor, so dust and spills do not escape into your workspace.

-

If cleaning is over 10% less efficient, more than 54,000 tons of material can end up on the floor.

-

Managing spills better means you need fewer rollers, belts last longer, and belts do not move too much.

-

The closed design lowers dust and contamination, so you meet safety and environmental rules.

-

You can control temperature and humidity better, so materials do not get ruined.

Reducing Material Breakage and Degradation

You need to keep fragile products safe while moving them. Tube belt conveyors move things gently, so items do not break and stay in good shape. Other conveyor types can damage fragile items more easily.

|

Conveyor Type |

Degradation Factors |

Rate of Degradation |

|---|---|---|

|

Tube Belt Conveyors |

Better resistance to wear, less volume lost in DIN test |

Lower |

|

Other Conveyor Types |

More wear because materials rub against the belt, especially hard materials |

Higher |

-

Tube belt conveyors resist wear better than other types.

-

Hard rocks and pellets wear out belts faster than soft things like coal.

-

Screw conveyors can break pieces because they grind the material.

You get the most benefits when moving delicate things like pasta, cereal, sugar, and soft fruits. Dangerous materials and powders also need gentle moving to stop contamination or explosions. Clean materials stay safe inside the tube system. Small and powdery things move well without waste.

If you move nuts, cereal, or snacks, you want to keep your products safe. Tube belt conveyors protect these items, so you lose less and make more money. Fast air transport can ruin over 10% of sensitive products, but gentle tube belt conveyors keep waste low.

Environmental and Workplace Safety

Dust and Emission Control

You want your workplace to be clean and safe. Tube belt conveyors help control dust and emissions better than most systems. The closed design keeps dust, spills, and bad particles inside. This protects workers and the environment. It is easier to follow strict rules from OSHA, the EPA, and local groups.

Here is how tube belt conveyors compare to other systems:

|

Aspect |

Tube Belt Conveyors |

Other Conveyor Systems |

|---|---|---|

|

Environmental Regulations |

Use enclosed systems to lower dust and spills |

Varies, often less focus on enclosure |

|

Compliance Requirements |

Must follow OSHA, EPA, and local laws |

Rules change by system type |

Keeping dust and emissions low helps you avoid fines. It also keeps your workplace healthy.

Enhancing Worker Safety

Tube belt conveyors help lower injury risks. Handling bulk materials by hand can cause accidents. In the past, 14% of mining accidents involved conveyors. Since 2007, 17 people have died working near belt conveyors. Most deaths happened when people got caught in moving parts.

You keep your team safe with these features:

-

Emergency stops that are easy to use and see

-

Guards that cover pinch points and moving parts

-

Warning signs and signals to show dangers

-

Interlock devices that stop the conveyor if guards are off

-

Dust and fire control systems for extra safety

You also get:

-

Guards to stop contact with dangerous parts

-

Alarms to warn before the conveyor starts

-

Sensors and alarms to check for problems

-

Clear signs to help everyone use the system safely

Less manual handling means fewer injuries. This makes your workplace safer for everyone.

Bulk Material Handling Versatility

Adapting to Different Materials

You need a conveyor that works for many materials. Tube belt conveyors are flexible and can move lots of things. You can use them for heavy rocks or soft foods. The closed tube keeps your materials safe from weather and dirt.

Here are some things you can move with tube belt conveyors:

-

Coal

-

Mineral ore

-

Stone

-

Grains

-

Cement

These conveyors also work for fragile products. Many food companies use them for items that break easily. The table below shows some examples:

|

Material Type |

Description |

|---|---|

|

Pet Food |

Often moved in tube belt conveyors. |

|

Snack Foods |

Good for many snack types. |

|

Coffee |

Needs gentle handling during moving. |

|

Nuts |

Easy to move and keep safe. |

|

Specialty Grains |

Works for different grain kinds. |

|

Breakfast Cereal |

Great for soft cereal pieces. |

|

Tea Blends |

Keeps tea blends safe while moving. |

Tube belt conveyors help keep your products clean and safe. The sealed tube blocks dust, rain, and sun. Your materials arrive in good shape.

Tip: If you move both tough and fragile things, you only need one system. Tube belt conveyors can do both jobs.

Navigating Complex Routes

Sometimes you need to move things across busy or rough places. Tube belt conveyors make this easy. The flexible design lets you set up the system to fit your space. You can run the conveyor around corners, up hills, or over long paths.

Some good things about this flexibility are:

-

Can go around sharp turns

-

Easy to put in small spaces

-

Fewer places where things spill

-

Protects from wind, rain, and sun all the way

You can build your conveyor to fit almost any area. This saves space and money on building changes. You also lower the chance of losing or ruining materials because the tube stays closed.

Note: Tube belt conveyors work in places other systems cannot. You can move things over hills, around machines, or through busy spots with no problem.

You get a system that fits your needs. Tube belt conveyors are a smart choice for any place that moves bulk materials.

Cost Efficiency and Reliability

Lower Maintenance Needs

You want a conveyor that saves time and money. Tube belt conveyors make maintenance easy and less often. The frames are welded and rounded, so food and dust do not hide. There are fewer fasteners, so you check and replace fewer parts. Motors are easy to reach, and enclosed motors handle cleaning better than open ones. You can clean these conveyors with wet or dry methods. Some systems let you clean without taking them apart. Clean-in-place features use many inlets and outlets.

-

Welded frames stop residue from hiding.

-

Fewer fasteners mean repairs take less time.

-

Enclosed motors last longer and need less care.

-

Wet and dry cleaning options fit your needs.

-

CIP methods save time and keep things running.

Tip: Less time on maintenance means lower costs and smoother work.

Consistent Performance

You need your conveyor to work every day. Tube belt conveyors give strong and steady performance. The tough build handles heavy use and hard materials. Real-time monitoring shows the conveyor’s status at any time. You can track service schedules and spot problems early. Maintenance teams get alerts and tips, so they fix issues fast.

Here is how you can track reliability:

|

Metric |

Description |

|---|---|

|

New Alerts |

Number of new alerts in the last 30 days |

|

Work Orders |

Total work orders created in the last 30 days |

|

Open Work Orders |

Work orders still open and waiting |

|

Open Work Requests |

Work requests that are currently open |

|

Alert to Work Order Duration |

Time from alert to work order completion |

You get fewer breakdowns and more uptime. Your belt conveyors keep running, so you reach your goals. Over time, you save money and avoid costly stops.

A reliable conveyor system helps you plan better and deliver on time.

Comparing Conveyor Systems

Tube Belt vs. Traditional Belt

Tube conveyor systems and traditional belt conveyors are very different. Tube conveyor systems use a closed tube to move materials. This keeps everything inside and stops spills. Dust does not escape, so you do not need extra dust control. Your products and the environment stay safer.

The table below shows how tube conveyor systems are better than traditional belt conveyors:

|

Criteria |

Pipe Conveyor Belt Systems (Tube Conveyor System) |

Traditional Conveyors |

|---|---|---|

|

Design |

Enclosed tubular design; adapts to curves and hills |

Open, flat belt; best for straight lines |

|

Material Spillage |

Zero spillage due to enclosed system |

Higher risk of spillage |

|

Dust Control |

Excellent; dust stays inside |

Needs extra dust control |

|

Environmental Impact |

Lower; less leakage and carbon footprint |

Higher; more cleaning needed |

|

Maintenance |

Needs special parts, but less frequent |

Easier, but may be needed more often |

|

Cost |

Higher at first, but saves money over time |

Lower at first, but costs add up |

|

Aesthetic/Regulatory |

Good for urban or sensitive areas |

Less suitable for strict rules |

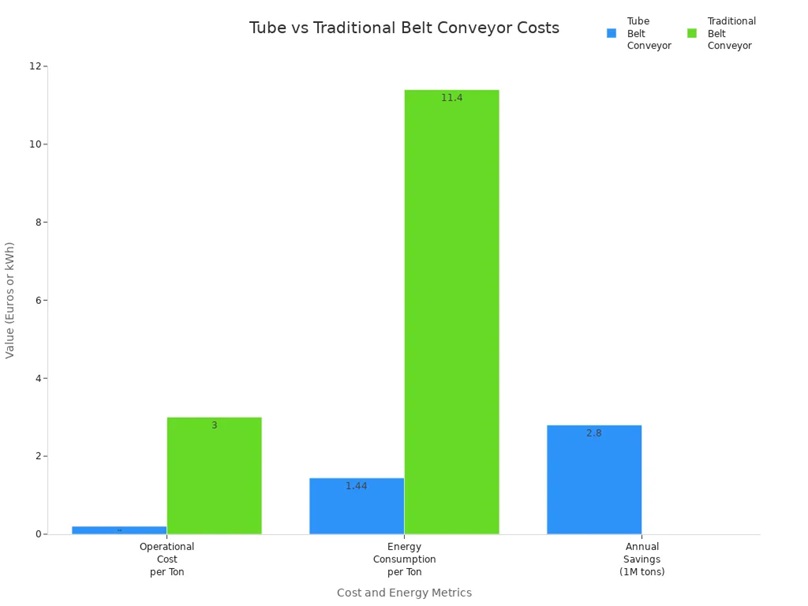

You save money every year with tube conveyor systems. You use less energy and spend less on cleaning. The chart below shows how much you can save:

Tube conveyor systems use only 1.44 kWh per ton. Traditional belt conveyors use 11.4 kWh per ton. You spend less money for each ton moved. Over a year, you can save up to 2.8 million Euros if you move one million tons.

Tube conveyor systems help you keep your workplace clean and safe. Your products stay protected, and you follow environmental rules more easily.

Tube Belt vs. Screw and Pneumatic

Tube conveyor systems work differently than screw and pneumatic conveyors. Screw conveyors use a spinning shaft to push materials. This makes more friction and uses more energy. Pneumatic conveyors use air to move things, but they can break fragile items and make dust.

The table below shows the differences:

|

Conveyor Type |

Energy Consumption |

Material Handling Efficiency |

|---|---|---|

|

Tube Belt Conveyors |

Lower |

Higher |

|

Screw Conveyors |

Higher |

Lower |

-

Tube conveyor systems use less energy because they move things smoothly.

-

Screw conveyors need more power because of friction.

-

Tube conveyor systems can move many types of materials, even fragile ones, without breaking them.

Tube conveyor systems give you better results. You save electricity and keep your products safe. You also avoid dust and spills.

Tube conveyor systems are the best choice for safety, efficiency, and saving money. You can move many materials over long distances and through tough places. You also protect your team and the environment.

You have lots of good reasons to pick tube belt conveyors. These systems move big amounts of material easily. They work with many types of materials. Tube belt conveyors last a long time and need little fixing. Many companies change to these systems for better capacity. They also want to spend less money and keep workers safe.

-

You can look at your current system and see what you need. You can plan and build a conveyor that fits your space.

-

Experts say you should check your system often. They also say training helps keep everyone safe and the system working well.

Talk to suppliers to get solutions made just for you and your needs.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported