A heavy duty jaw crusher is a strong machine. It is used first to crush big rocks into smaller pieces. Jaw crushers are used in mining, construction, and recycling. They can break hard materials easily. The first jaw crusher was made in 1858. Since then, designs have changed a lot. The Hypro-Crush® is a newer model. It uses less power and works better.

-

The world market for jaw crushers was about USD 2.48 billion in 2023. It may grow to USD 3.49 billion by 2032. This is because people want machines that crush well.

-

New Jaw Crusher Technology helps save more energy. It also makes the machines work better.

Jaw Crusher Overview

What Is a Jaw Crusher

A jaw crusher is a strong and slow machine. People use it to crush big rocks, ore, or concrete. The machine has two plates called jaws. One jaw does not move. The other jaw moves back and forth. The moving jaw pushes the material against the fixed jaw. This makes the material smaller.

Jaw crusher technology has changed a lot over time. Old machines were simple. New machines have more advanced parts. Single and double toggle mechanisms make crushing easier. Factories in Tampere, Finland, have made crushers for many years. The C Series jaw crusher came out in 1976. Research and development keep jaw crushers useful.

Jaw crushers are used in many industries. They are important in mining, construction, and recycling. New jaw crusher technology gives better results and saves money. The C6X model has a bigger opening and better crushing motion. This helps you get more work done and use less energy than other primary crushers.

Here are the main technical specifications for a jaw crusher:

-

Feed Size: The biggest material you can put in the machine.

-

Capacity: How much material the crusher can handle each hour.

-

Jaw Crusher Type: You can pick single toggle or double toggle.

-

Jaw Crusher Size: The width and length of the jaw opening.

-

Crushing Mechanism: How the jaw plates move and crush things.

-

Power Requirements: The kind of motor used, electric or diesel.

-

Adjustment Mechanism: Lets you change the size of crushed material.

-

Wear Parts: Jaw plates and liners that need replacing sometimes.

-

Operating Weight: The total weight of the jaw crusher.

-

Operating Conditions: The place where you use the crusher.

-

Safety Features: Includes overload protection and automatic lubrication.

Main Functions

Large-scale jaw crushers do many important jobs in industry. They help you get raw materials ready for the next step.

-

Primary Crushing: Jaw crushers break big rocks into smaller pieces. This is the first step in mining and quarrying.

-

Ore Extraction: In mining, they crush large pieces of ore.

-

Material Reduction: Jaw crushers make raw materials smaller and more even.

-

Aggregate Processing: You can make different sizes of aggregates for building.

-

Sorting and Classification: These machines sort materials by size for uniform products.

-

Demolition: Jaw crushers break down concrete, bricks, and other materials during demolition.

Jaw crusher technology is special because it works fast and well. In quarries, you can crush lots of aggregate quickly. This helps you make more and spend less. Many companies in Southeast Asia, the Middle East, and Africa use advanced jaw crusher technology to improve their work.

Jaw crushers have been around for a long time. They started as simple machines in the 1800s. New features and better designs keep them important today. You can trust jaw crusher technology for hard jobs and high output.

How Jaw Crushers Work

Operating Principle

You may wonder how jaw crushers work. These machines use a simple idea. The way they work is like animal jaws. Inside the machine, there are two jaws. One jaw does not move. The other jaw moves back and forth. This movement happens because of a special shaft. The shaft turns and pushes the moving jaw.

-

The jaw crusher uses compression to crush things.

-

Material sits between the fixed jaw and the moving jaw.

-

The moving jaw swings forward and backward.

-

When the jaw goes up, the angle between jaws gets bigger.

-

The material gets squeezed and crushed as the jaws close.

Jaw crushers work by using strong force. This force can break very hard rocks. You get steady and strong crushing every time.

Here is a table that shows how jaw crushers are different from other crushers:

|

Crusher Type |

Mechanism of Action |

Force Type |

|---|---|---|

|

Jaw Crusher |

Utilizes compressive force |

Compressive |

|

Impact Crusher |

Relies on force of impact |

Impact |

You can see jaw crushers use compression. Other machines use impact or other forces.

Crushing Process

The crushing process in jaw crushers has several steps. You start with big rocks or ore. The machine makes these materials smaller by primary crushing. This step is very important in mining and building.

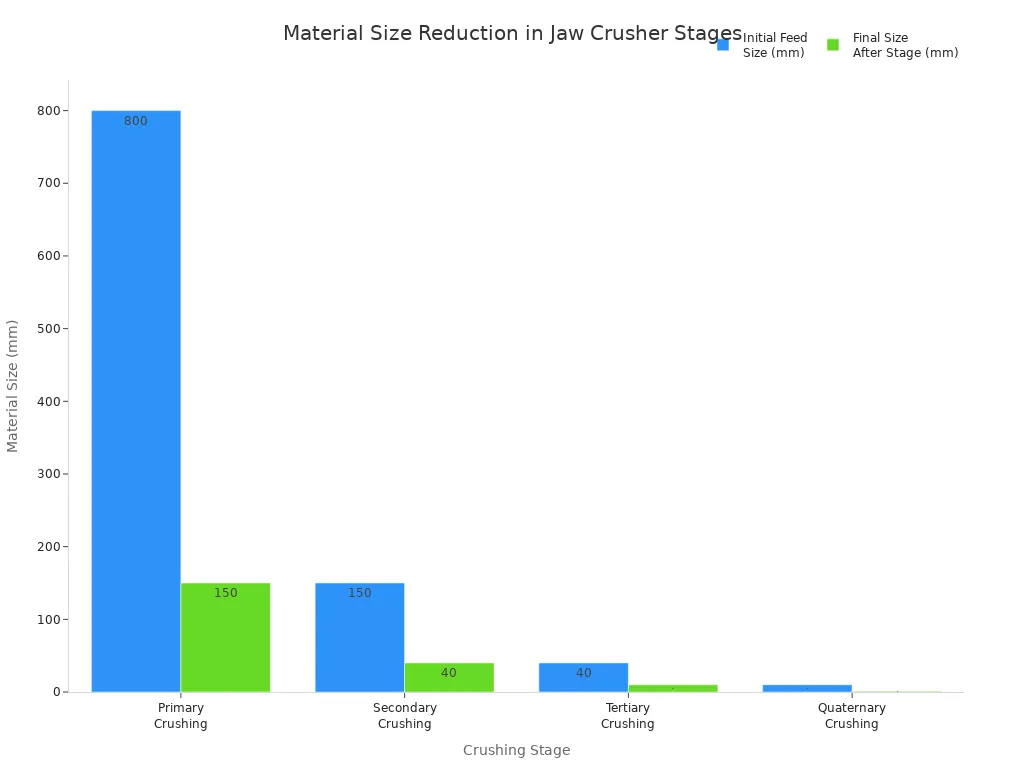

Here is a table that explains each step of the crushing process:

|

Crushing Stage |

Objective |

Equipment Used |

Initial Feed Size |

Size Reduction |

Process Details |

|---|---|---|---|---|---|

|

Primary Crushing |

To make large materials smaller and easier to handle. |

Jaw Crusher |

500 mm to 800 mm |

125 mm to 150 mm |

Big pieces go into the jaw crusher. Strong force breaks them down. |

|

Secondary Crushing |

To make the material from primary crushing even smaller. |

Cone Crusher, Impact Crusher |

125 mm to 150 mm |

20 mm to 40 mm |

Material from the first crusher goes into secondary crushers for finer size. |

|

Tertiary Crushing |

To get very fine material for special needs. |

Fine Jaw Crushers, Cone Crushers |

20 mm to 40 mm |

1 mm to 10 mm |

Needed for making fine aggregates like sand. |

|

Quaternary Crushing |

To make ultra-fine materials for special uses. |

Vertical Shaft Impact Crushers, Specialized Fine Cone Crushers |

1 mm to 10 mm |

Less than 1 mm |

Used for high-quality jobs needing very fine materials. |

You put big rocks into the jaw crusher. The machine uses primary crushing to make rocks smaller. After this, you use other crushers for more crushing. Each step makes the material smaller and better for use.

Tip: Crushing works best when you pay attention to some things. You should look at feed size, product size, capacity, reduction ratio, and material type. The design of the machine and how you use it also matter.

Here are some important things that affect how well jaw crushers work:

-

Feed size

-

Product size

-

Capacity

-

Reduction ratio

-

Material characteristics

-

Equipment design and configuration

-

Operational parameters

You get the best results by picking the right settings and keeping your machine in good shape.

Jaw crushers are easy to use, but you need to know each step. You start with primary crushing for big pieces. Then you use secondary and tertiary crushing for smaller pieces. This helps you get the right size for your job.

Jaw Crusher Technology

Key Advancements

Jaw crushers have changed a lot over time. New technology makes them safer and smarter. Many jaw crushers use hydraulic systems now. These systems help you clear blockages easily. You can adjust settings without touching dangerous parts. The machine is protected from overload. You just press a button to do these things.

Modern concrete jaw crushers use automation and digital monitoring. Sensors check temperature and load all the time. This helps you keep the crusher working well. You can find problems early and fix them before they get worse. Some systems use artificial intelligence. They change speed and power for different rock sizes. This saves energy and lets you do other jobs.

Note: Automation and digital tools help you work faster. They keep jaw crushers running longer. Workers stay safe because they do not need to do risky jobs.

Here are some new features in advanced jaw crushers:

-

Hydraulic chamber clearing helps you remove blockages safely.

-

Hydraulic overload relief protects the machine from damage.

-

Hydraulic adjustment lets you change output size quickly.

-

Smart sensors help with real-time monitoring and maintenance.

-

Automation systems keep the crusher working smoothly.

Mobile Jaw Crushers

Sometimes you need to move your crushing machine. Mobile jaw crushers make moving easy. These machines work well at different sites. A mobile jaw crusher is a track-mounted machine. You can set it up fast and start working soon.

Mobile jaw crushers have many benefits. You do not need extra buildings or long setup times. Their compact design saves space. Crushing materials on-site helps the environment. It lowers emissions and pollution.

Here is a table that compares mobile and stationary jaw crushers:

|

Feature |

Mobile Jaw Crushers |

Stationary Jaw Crushers |

|---|---|---|

|

Cost Efficiency |

Lower cost, no extra buildings |

Higher cost, needs more buildings |

|

Setup Time |

Quick and easy to move |

Slow and harder to move |

|

Space-Saving Structure |

Small and saves space |

Big and needs more space |

|

Enhanced Flexibility |

Easy to move to new places |

Stays in one place |

|

Reduced Environmental Impact |

Less pollution |

More pollution |

|

Lower Capacities |

Smaller and lighter |

Bigger and stronger |

|

Limited Customization |

Fewer choices |

More choices |

|

Cool-Down Needs |

Needs cool-down breaks |

No cool-down breaks needed |

Pick mobile jaw crushers if you want to move fast and save space. If you need more power and options, stationary jaw crushers may be better for you.

Types of Jaw Crushers

Single Toggle

Single toggle jaw crushers are simple machines. They have two jaw plates. One plate stays still. The other plate moves. The plates make a V-shaped space called the nip angle. The moving jaw goes in an oval path. It moves because of a special shaft and a toggle plate. This helps crush rocks well.

-

The rocks get squeezed between the jaw plates.

-

Crushed rocks come out at the bottom.

-

You can change the output size by adjusting the closed side setting (CSS).

-

Single toggle jaw crushers make less fine material than impact crushers.

-

They work best for the first crushing step. Their reduction ratio is about 4 to 1.

People use these crushers first to break big rocks. After that, they use other machines for more crushing.

Double Toggle

Double toggle jaw crushers look different. They have two big jaw plates that move to crush rocks. The special shaft sits behind the moving jaw. This keeps it safe from damage. These crushers have more parts and are heavier than single toggle crushers.

Double toggle jaw crushers are very strong. People use them for hard crushing jobs. They can crush tough and rough rocks with a high Work Index. This makes them good for hard work where you need strong machines. You see them where you need secondary crushing for very hard rocks.

Double toggle jaw crushers are made for hard jobs. They last a long time and can handle lots of pressure.

Comparison

You might wonder how single and double toggle jaw crushers are different. Here is a table to show you:

|

Feature |

Single Toggle Jaw Crusher |

Double Toggle Jaw Crusher |

|---|---|---|

|

Size |

Smaller, lighter |

Larger, heavier |

|

Moving Parts |

Fewer |

More |

|

Throughput |

Higher |

Lower |

|

Eccentric Location |

Top of swinging jaw |

Behind swinging jaw |

|

Motion |

Up and down, swinging |

Swinging only |

|

Application |

Softer materials, primary crushing |

Hard, abrasive materials, secondary crushing |

|

Design Complexity |

Simpler |

More complex |

|

Shock Loading |

More susceptible |

Less susceptible |

|

Productivity |

Higher due to dual motion |

Limited by restricted motion |

|

Energy Efficiency |

Better |

Lower |

Single toggle jaw crushers work faster and use less energy. Double toggle jaw crushers are stronger for tough rocks. Pick the right jaw crusher for your job, the material, and if you need first or second crushing.

Jaw Crusher Components

Main Parts

Jaw crushers have many parts that work together. Each part helps the machine crush rocks. You need to know these parts to see how jaw crushers work.

Here is a table that lists the main parts and what they do:

|

Component |

Function |

|---|---|

|

Jaw Plates |

Directly contact the material being crushed; made from high-quality manganese steel for wear resistance. |

|

Frame |

Provides structural integrity and support; made from heavy-duty steel to withstand crushing forces. |

|

Eccentric Shaft |

Converts rotary motion into back-and-forth motion for crushing; requires proper lubrication. |

|

Toggle Plate |

Acts as a safety device; absorbs shock loads and prevents damage to other components. |

|

Drive Motor |

Powers the jaw crusher; can be electric or hydraulic, requiring appropriate power selection. |

|

Bearings |

Support movement of components; reduce friction and enhance efficiency through proper lubrication. |

Each part has its own job. Jaw plates crush the rocks. The frame holds all the parts together. The eccentric shaft moves the jaw plates back and forth. The toggle plate keeps the machine safe from damage. The drive motor gives the machine power. Bearings help the moving parts move easily.

Tip: Take care of these parts. Your jaw crusher will last longer and work better.

Construction Materials

Jaw crushers need to be strong for hard jobs. That is why each part uses tough materials.

-

Jaw plates are made from manganese steel. This metal does not wear out fast.

-

The frame is made from heavy-duty steel. It holds up the whole machine.

-

The eccentric shaft uses alloy steel. This material is strong under pressure.

-

Bearings are made from hardened steel. They help the parts move smoothly.

-

The toggle plate uses cast iron or steel. It takes in shocks during crushing.

These strong materials help jaw crushers work in rough places. You can use them for mining, building, and recycling. When you pick a jaw crusher, look at the materials used. Good materials mean better crushing and a longer life.

Applications of Jaw Crushers

Mining

Jaw crushers are used a lot in mining. They do the first job of crushing hard rocks and ores. You can use them for iron ore, coal, copper, and gold. Here are some facts about jaw crushers in mining: Mining uses jaw crushers more than any other industry. In 2024, mining made up 68% of all jaw crusher use. Over 40,000 jaw crushers were working in mines in 2024. Jaw crushers do the first crushing of tough rocks. This gets the rocks ready for the next step. Using jaw crushers in mining makes crushing easier and more dependable. You get the right size rocks for the next machine.

Construction & Demolition

Jaw crushers help with construction and demolition work. They crush big pieces of concrete and asphalt into smaller bits. This saves time and money. Crushing waste at the site means you do not need to move heavy debris far away. Many companies use mobile jaw crushers now. These machines can lower moving and dumping costs by up to 40%. Recycling old materials helps the environment and meets new building rules. It also keeps the work area neat and tidy.

Recycling

Jaw crushers are important for recycling jobs. They break big chunks of concrete and other materials into smaller pieces. This means less waste goes to landfills. You also need fewer new materials. Here is how jaw crushers help with recycling: They crush concrete so it is easier to reuse. You can use crushed concrete in new buildings, which saves money. Jaw crushers can separate steel rebar from concrete. This lets you recycle both steel and concrete. These machines help builders follow rules about cutting down waste. Jaw crushers are used in many recycling jobs for making new aggregate. They turn waste into useful material, making projects better for the planet.

Benefits of Jaw Crushers

Efficiency

Jaw crushers help you work faster and save money. They make crushing easier and use less energy. If you get your material ready first, you do not waste power. Feeding the machine with the right size helps it work better. Keeping the feed steady gives you good results. Checking and fixing the machine often stops big problems.

-

Get material ready before crushing to save energy.

-

Use the right size and keep it steady for better results.

-

Check and fix the machine often to stop breakdowns.

If your jaw crusher does not work well, you pay more. Sometimes, costs can go up by twenty percent. Good jaw crushers help you spend less and stay on budget. You also get more work done when your machine runs well.

Tip: When your crusher works well, you get more product. You use less effort and spend less money.

Durability

Jaw crushers are made to last in tough places. They work well in mines and demolition sites. Many have bigger openings and special movement for better crushing. The modular design makes it easy to change parts and fix things.

-

Welded frames make the machine strong.

-

Good materials help jaw crushers last longer.

-

New systems like Sandvik’s ACS-j help you check and control lubrication and hydraulic settings.

These things protect your machine and help it last longer. Jaw crushers give you less downtime and fewer repairs. You get strong crushing and good results every year.

Choosing a Jaw Crusher

Material Considerations

When selecting the right jaw crusher, you need to look at the material you want to crush. Different materials have different properties. Some are hard, some are soft, and some are very abrasive. If you choose the wrong machine, you may see faster wear or even damage. You should check the material’s hardness, toughness, and cost. The table below shows what to look for:

|

Material Property |

Requirement |

|---|---|

|

Contact Stress |

Must not cause damage |

|

Toughness |

Not lower than 1.3 x 10° Pa.m°° |

|

Thermal Expansion |

Not beyond 10 x 10° |

|

Hardness |

Not lower than 4.9 x 10’ Pa |

|

Yield Strength |

Not beyond 1.80 x 10’ Pa |

|

Cost |

Not beyond 10 USD/Kg |

Tip: Using standard manganese steel instead of special alloys can cause 30–50% faster wear if you crush abrasive rocks. Always match the jaw plates to your material.

Capacity & Output

You want high production capacity and the right output size for your job. The closed-side setting (CSS) controls both. A bigger CSS gives you more capacity but larger pieces. A smaller CSS gives you finer output but less production. The table below helps you see the difference:

|

CSS Setting |

Capacity Impact |

Typical Output Size |

|---|---|---|

|

100 mm |

Maximum throughput |

150-200 mm |

|

50 mm |

25% capacity reduction |

75-100 mm |

|

25 mm |

40-50% capacity drop |

35-50 mm |

-

Harder materials like granite can lower capacity by 30-40%.

-

Wet materials may cause a 15-25% loss in capacity.

-

If you pick a crusher that is too small, you risk breakdowns. Too large, and you waste power and space.

Operational Needs

You must think about your work site and how you use the crusher. Speed, material type, and crusher design all affect crushing and production. The table below shows what to consider:

|

Operational Factor |

Impact on Performance |

|---|---|

|

Speed |

Changes throughput and product size. Higher speed means more production but more wear. |

|

Material Characteristics |

Harder rocks need slower speeds to avoid damage. |

|

Crusher Design |

Single-toggle and double-toggle work best for different jobs. |

|

Desired Product Size |

Finer products need higher speeds. |

Note: A 10% mismatch in crusher size can cut your throughput by 30% or raise wear costs by 50%. Always size your jaw crushers to your needs for the best crushing results.

You now know what a jaw crusher does. You learned how it works and the main types. You also saw the important parts and where you can use jaw crushers. When picking a jaw crusher, think about these things:

-

What the material is like and how hard it is

-

How much you want to crush each hour

-

How big your project is

-

How much it costs to move and run the machine

-

If you need to move the crusher and what features it has

-

If the maker helps you fix and care for the machine

If you choose the right jaw crusher for your job, you save money. You also get better results. Always look at your project needs before you pick a jaw crusher.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported