Tunnel boring machine costs can be $5 million for small ones. The biggest machines can cost over $100 million.

-

Most TBMs cost around $15 million each.

-

Regular construction TBMs usually cost $500,000 to $3 million.

Custom-built TBMs are made for special projects. These machines work better and may save money later. They often cost more at first. Knowing all the cost details helps you plan well and avoid problems.

Key Takeaways

-

Tunnel boring machines (TBMs) can cost from $5 million to over $100 million. Knowing the price range helps you plan your budget well.

-

Picking the right TBM size and type is very important. Smaller machines cost less. Bigger, custom machines may save money later.

-

You can rent a TBM for short jobs. Renting lowers starting costs. It gives you more choices and you do not have to own the machine.

-

Remember extra costs like moving, putting together, and fixing the TBM. These costs can change your total budget a lot.

-

Good planning and talking about prices can help you save money. Buying in bulk and signing long deals often gets you better prices.

Tunnel Boring Machine Costs

Cost Range Overview

Tunnel boring machine costs can be very different. In 2025, most machines cost $10 million to $100 million. A regular tunnel boring machine costs about $20 million. Smaller machines cost less money. The biggest and most advanced machines cost over $100 million. For example, a TBM with an 8-meter diameter costs about $8 million. A TBM with a 16-meter diameter can cost $76 million or more.

Many things affect the price of a tunnel boring machine. Size, technology, and where the tunnel is matter. In Asia-Pacific, like China and India, there are more TBMs because of big projects. North America also uses more TBMs now. The California High-Speed Rail project used a TBM that cost $58 million.

Tunnel boring costs can be hard for small companies. High starting costs and extra expenses make it tough to buy these machines. You need to plan well to handle these costs.

Price by Size and Type

The price of a tunnel boring machine changes with size and type. Here is a table that shows how size affects price:

|

Size |

Price Range |

Key Features |

|---|---|---|

|

Small |

$6,200 - $590,000 |

Type (EPB, slurry, hard rock), power, technology |

|

Medium |

$1M - $15M |

More power, larger diameter, advanced controls |

|

Large |

$30M - $100M+ |

High automation, big diameter, custom features |

Different types of machines work in different ground:

-

Slurry TBMs are best for soft ground.

-

EPB TBMs work in mixed soils.

-

Hard rock TBMs dig through tough rock.

Other things that change the price are diameter, power, automation, and brand. Tunnel boring costs go up with bigger and better machines.

A simple rule is $1 million for each meter of diameter. For example, a 6-meter TBM may cost less than $1 million because many people want them. Subway TBMs can cost $700,000 to $500,000 because of competition.

Customization Impact

Sometimes you need a custom TBM for your tunnel. Custom machines cost more money. Engineers design the machine for your tunnel's ground and size. This makes the tunnel boring machine cost more.

|

Step |

Description |

|---|---|

|

Design and Customization |

Engineers build the TBM for your project's specific ground and tunnel needs. |

Custom TBMs work better for special tunnels. You pay more at first, but you can save money later. Custom machines help avoid delays and work better. Tunnel boring costs go up with custom features, but you get a machine that fits your tunnel.

Tip: Always check if you need a custom TBM or if a regular one will work. Custom machines help avoid problems underground, but they cost more.

Factors Affecting Tunnel Boring Costs

Machine Specifications

Machine specifications matter a lot for tunnel boring costs. The diameter, length, and power of the machine change the price. Bigger diameters need stronger materials and better technology. This makes the machine cost more money. Longer machines use more parts and need more work to build. Machines with higher power cost more because they dig faster and handle tough ground. Usually, you pay about $1 million for each meter of diameter. So, bigger tunnels always cost more. You also need to think about the rock conditions. TBMs are much more sensitive to rock than other ways. The size can make costs four to five times higher than regular digging.

Tip: Always check the ground and tunnel size before picking a TBM. This helps you avoid surprises in costs and labor.

Technology Features

New technology features can make tunnel boring costs go up. Many new machines use automation and real-time monitoring. These systems help you dig safer and faster, but they cost more at first. AI-driven machines can watch the ground and change settings by themselves. This lowers mistakes and makes work smoother. You pay more for these features, but they can save money on labor later. Machines like 'Prufrock' work much faster than older ones. This means you finish projects sooner and save on labor.

|

Advanced Technology Feature |

Impact on Costs |

|---|---|

|

Automation Systems |

Higher starting costs and better safety |

|

Real-time Monitoring Technologies |

More costs for monitoring, but better performance |

-

Automation and monitoring are common in new TBMs.

-

These features make work safer and lower labor costs.

Manufacturer Influence

The company that makes your tunnel boring machine changes the cost. Famous brands like Komatsu Ltd., Terratec Ltd., and IHI Corporation are trusted. You might pay more for their machines, but you get better help and quality. Some companies offer special designs for your project. This can change tunnel boring costs and labor costs. Trusted brands cost more at first, but you save money on repairs and labor later.

|

Manufacturer |

Founded |

Headquarters |

Specialization |

|---|---|---|---|

|

Komatsu Ltd. |

1921 |

Tokyo, Japan |

Construction and mining equipment |

|

Terratec Ltd. |

1995 |

Puchong, Malaysia |

Tunneling and underground construction |

|

IHI Corporation |

1853 |

Tokyo, Japan |

Engineering solutions and tunneling |

You should compare brands and ask about support and labor costs. This helps you know all the things that change tunnel boring costs.

Additional Tunnel Boring Costs

Transportation and Assembly

You have to think about moving and building the machine. Getting a tunnel boring machine to your site costs a lot. Sometimes, it can cost millions of dollars. Renting a 7-meter TBM might cost 10 million euros. You also pay around 5 million euros for extra tools. These costs cover shipping, cranes, and special trucks. Putting the machine together takes time and skill. You need to pay workers who know how to build it. You also pay for materials, especially if you need custom parts or extra help.

Tip: Make sure your site is big enough for the equipment. Good access helps you avoid extra costs.

Operation and Maintenance

Running a tunnel boring machine costs more money. You pay for fuel, spare parts, and regular checkups. Maintenance costs change if you use a new or old machine. New TBMs need less fixing at first. Old ones can save you money on materials. The table below shows how much you can save:

|

Project Complexity |

Cost Savings (%) |

|---|---|

|

Simple |

75% |

|

Complex |

20% |

You must keep your machine working well to stop delays. Over 60% of TBMs break down because of fixing or custom problems. Labor costs go up when you need skilled workers to repair things. Insurance also adds to the cost, especially for big jobs.

Staffing and Ancillary Equipment

You need a good team for tunnel boring. You pay workers who know how to run the machine. Here is what you should expect:

-

You pay for special crews and tech help.

-

You need workers on site all the time, so costs stay high.

-

Setting up and changing things for the ground adds to costs.

-

Material costs go up if you need extra tools or spare parts.

You should plan for safety gear, backup power, and monitors. These things help your team stay safe and keep costs down. Labor costs can be higher if the ground is tough or hours are long.

Note: Planning for workers and equipment early helps you avoid surprise costs.

Financing for a Tunnel Boring Machine

Purchase vs. Rental

You need to choose if you want to buy or rent a tunnel boring machine. Buying costs a lot at first, but you own the machine. Renting costs less at the start and gives you more choices. Look at this table to see the differences:

|

Aspect |

Purchasing |

Renting |

|---|---|---|

|

Initial Costs |

High upfront investment |

Lower initial costs |

|

Cash Flow Impact |

Can strain cash flow |

Helps maintain cash flow |

|

Maintenance |

Owner responsible for all costs |

Often included in rental agreements |

|

Asset Value |

Builds asset value through ownership |

No asset value built, ownership remains with lessor |

|

Flexibility |

Less flexible, tied to ownership |

Flexible for seasonal or one-off projects |

|

Technology Risk |

Risk of becoming outdated |

Opportunity to upgrade regularly |

|

Tax Advantages |

Depreciation offers potential tax benefits |

Treated as operating costs, deductible |

|

Long-term Costs |

Potentially lower total expenses over time |

Cumulative payments may exceed purchase price |

Renting a tunnel boring machine costs about $100 to $300 each hour. If you rent for a long time, you might pay less. You also pay for moving the machine, insurance, and sometimes extra workers. Renting is good for short jobs or if you do not want old machines.

Tip: Always read your rental contract carefully. Check if fixing and worker costs are included.

Refurbished Options

You can save money by picking a refurbished tunnel boring machine. New machines can cost over $50 million. Refurbished ones cost much less and work almost like new if rebuilt well. You can save up to 75% for easy jobs and 20% for hard ones. If you use a refurbished machine for many jobs, you can save at least 30% compared to buying new.

-

Refurbished machines work well if rebuilt right.

-

The price depends on the brand and how much work was done.

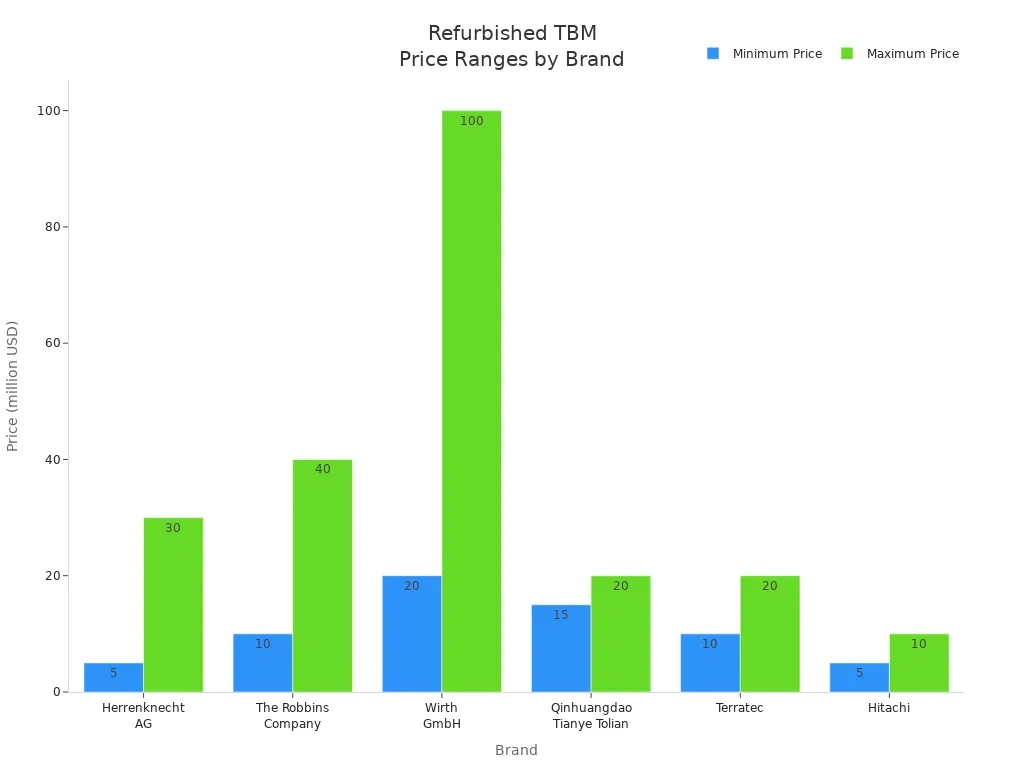

Here is a chart that shows prices for refurbished tunnel boring machines from different brands:

You should check the machine’s past and ask about old worker costs before you buy.

Budget Planning

Good budget planning helps you keep costs low and avoid problems. Set clear goals and make a detailed plan. Pick the best tunnel boring machine for your job and use new technology to save time. Hire a skilled team to run the project and keep worker costs down. Use just-in-time delivery and local suppliers to stop delays. Always plan for risks and have backup plans ready.

Note: Buy your tunnel boring machine separately from other things. This helps you focus on how it works and risks.

You can pay for equipment over 2 to 5 years. Monthly payments for $100,000 are about $2,000 to $2,500. Payments change if you buy new or used machines or if your company is new. Careful planning helps you manage worker costs and keep your project going well.

Tunnel Construction Cost Examples

Metro Project Case

Metro projects show how tunnel costs can change. In New York, the SAS Phase 1 project had many different costs. Some parts cost $4,069 for each cubic meter. Other parts cost up to $15,780 for each cubic meter. The price changed because of the tunneling method and ground conditions. Metro tunnels often go under busy streets and old buildings. They also fit into small spaces. These things make costs go up. You need extra safety and careful work in these places. Metro tunnel projects in cities usually cost more than ones in open areas.

Infrastructure Tunnel Case

Infrastructure tunnels, like highways or railways, have different costs. In Germany, some tunnels cost about €200 for each cubic meter. Harder projects can cost over €800 for each cubic meter. The Stuttgart-Ulm high-speed line had tough ground. Costs stayed below €1,000 for each cubic meter in 2010 Euros. These numbers show tunnel costs can change a lot. Where the tunnel is, the ground type, and project size all matter. You might pay less for tunnels in rural places or where digging is easy.

Lessons Learned

You can learn many things from old tunnel projects:

-

Ground problems cause most delays and extra costs.

-

Bad project management makes tunnel costs go up.

-

Working with engineers, planners, and workers helps keep tunnel projects on track.

-

Digital twin technology helps you find problems early and save money.

-

The Channel Tunnel had tough ground, so costs were much higher.

-

Using tunnel boring machines and good equipment helps with safety and engineering, but you still need to watch costs.

Tip: Always check the ground and plan your tunnel team well. Good planning and teamwork help you avoid surprises and control costs.

Cost-Saving Tips

Efficient Planning

Smart planning helps you save lots of money. Pick the tunnel boring machine that fits your project. Use a machine that matches the ground type. EPB TBMs and Slurry TBMs work best for soft ground. VD or Dual Mode TBMs help with mixed ground. AI-driven TBMs make work faster and safer.

Make a clear schedule before you start. Plan each part of the project step by step. Buy or rent equipment only when you need it. This keeps your budget safe. Set up a maintenance plan early. Regular checkups stop breakdowns and keep your machine working. Predictive maintenance can warn you about problems early.

Tip: Always check warranty choices and write down service dates. This helps you avoid big repair costs.

Negotiation Strategies

You can spend less by talking with suppliers. Ask for discounts if you buy many machines or parts. Make long-term deals with vendors. These deals give you better prices and more help.

Leasing saves money for short projects. Try to get good lease deals. Compare offers from different companies. Pick contracts that include fixing and support. This stops surprise costs.

|

Strategy |

Benefit |

|---|---|

|

Bulk purchasing |

Lower price per unit |

|

Long-term contracts |

Stable pricing and support |

|

Lease negotiation |

Flexible terms and lower costs |

Second-Hand TBMs

Buying second-hand TBMs can save you lots of money. Many projects use refurbished machines that work almost like new. You pay less at first and still get good results. Always check the machine’s past and ask for service records.

Leasing used TBMs is also a smart choice. This gives you more options and keeps your money safe. Many companies sell certified machines with warranties. You get peace of mind and save money too.

Note: Always look over second-hand machines before you sign anything. A good check helps you avoid hidden problems and extra costs.

You have learned about the main costs for tunnel boring machines. You need to pay for the machine and extra tools. There are also costs that keep coming as you use it. You can buy, rent, or pick a refurbished machine. Planning ahead helps you avoid problems and surprises.

-

Check all your costs before you begin your project.

-

Look at different ways to pay so you stay on budget.

Good budgeting helps you build better tunnels. Use this guide to make smart choices and keep your spending low.

FAQ

How much does a tunnel boring machine cost?

You can expect to pay between $5 million and $100 million for a tunnel boring machine. The price depends on size, type, and technology.

Can you rent a tunnel boring machine?

You can rent a tunnel boring machine for short projects. Rental costs range from $100 to $300 per hour. Renting helps you save money if you do not need the machine for long.

What extra costs should you plan for?

You need to plan for transportation, assembly, staffing, and maintenance. These costs can add millions to your budget. Always check for insurance and spare parts.

Tip: Ask your supplier for a full cost breakdown before you start.

Is buying a used tunnel boring machine a good idea?

Buying a used tunnel boring machine can save you up to 75% on simple projects. You should check the machine’s history and ask for service records.

|

Option |

Savings Potential |

Key Consideration |

|---|---|---|

|

Used TBM |

High |

Check condition |

|

New TBM |

Lower |

Latest technology |

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported