-

You should pick a Jaw Crusher Machine that fits your material and project.

-

If you choose wrong, the jaw can wear out or get blocked, like below:

Failure Type Description Jaw Wear This happens more in single shaft jaw crushers. It makes the machine work less well. Choking This happens when the output does not match the input. It means the jaw crusher is not the right one. -

Always look at crushing capacity, feed size, and safety.

-

Good mining equipment from NHI at nhiglobalequip helps you stop these problems.

1. Define Project Needs

To pick the right Jaw Crusher Machine, you need to know your project needs. You should think about a few things before you choose.

Material Type

First, you must know what material you want to crush. Hardness and abrasiveness change how the Jaw Crusher Machine works. If your material is tough, you need a strong machine. Tough materials need more energy and cause more wear. Here is a table that shows how different materials use energy and work:

| Material Type | Specific Energy (kWh) | Performance (Mg/h) | Crushing Energy (%) |

|---|---|---|---|

| PMMA | 1.63 | 0.05 | 66.04 |

| PP | 0.79 | 0.1 | 47.78 |

- Hardness

- Abrasiveness

- Size of raw material

- Final size needed

- Reduction ratio

- Mobility

- Adjustability

- How much material you will process

Output Size

You also need to pick the final size for your crushed material. The output size changes how much you can crush each hour. Bigger output sizes let you crush more each hour. Smaller output sizes slow down the work because the machine works harder.

| Output Size | Tons per Hour (TPH) Impact |

|---|---|

| Larger Output Sizes | Higher throughput |

| Smaller Output Sizes | Lower TPH because it takes more time |

Tip: Pick the output size that fits your project for better results.

Capacity

You should figure out how much you need to crush each day. Start by looking at the material type. Then, check the input and output sizes. Next, look at how much you need to crush daily and at busy times. Make sure the Jaw Crusher Machine can handle your needs. If the machine is too small, you might have delays. If it is too big, you might waste money.

- Begin with the material type.

- Look at input and output sizes.

- Check daily and peak amounts.

- Think about setup and if you need to move it.

- Make sure you follow local rules.

Site Conditions

Your site’s ground, access, and weather matter when you choose. If your site is rough or hard to reach, you may need a mobile Jaw Crusher Machine. Weather can change how the machine works. Wet or cold places may need special features.

Note: Always check your site before you pick a machine.

2. Jaw Crusher Machine Features

When picking a Jaw Crusher Machine, you should look at key features. Each feature helps the machine work better for your project.

Size & Feed Opening

You need to match the size and feed opening to your material. A bigger feed opening lets you crush larger rocks. This helps stop blockages. Here is a table with common sizes:

Jaw Size Feed Size Discharge Size Tons per Hour Weight (lbs) 6" x 10" 5.5" 3/4" - 2" 1 - 3 1600 8" x 12" 7.5" 3/4" 2 - 6 N/A Tip: Make sure your feed size fits the machine’s opening. This helps you avoid choking.

Power & Efficiency

You want a Jaw Crusher Machine that saves power and works well. Different brands have special features for better results.

Brand Model Power Consumption Efficiency Features Sandvik QJ341 Advanced hydraulic drive Easy controls, strong materials Metso C106 Monitoring systems Tracks how well it works in real time Terex J-1480 Hydrostatic/electric Can crush up to 750 metric tons each hour Keestrack B3 Diesel-hydraulic/hybrid Small size, big jaw opening Note: Hydraulic closed side setting adjustment lets you control output size. It also helps keep workers safe.

Durability

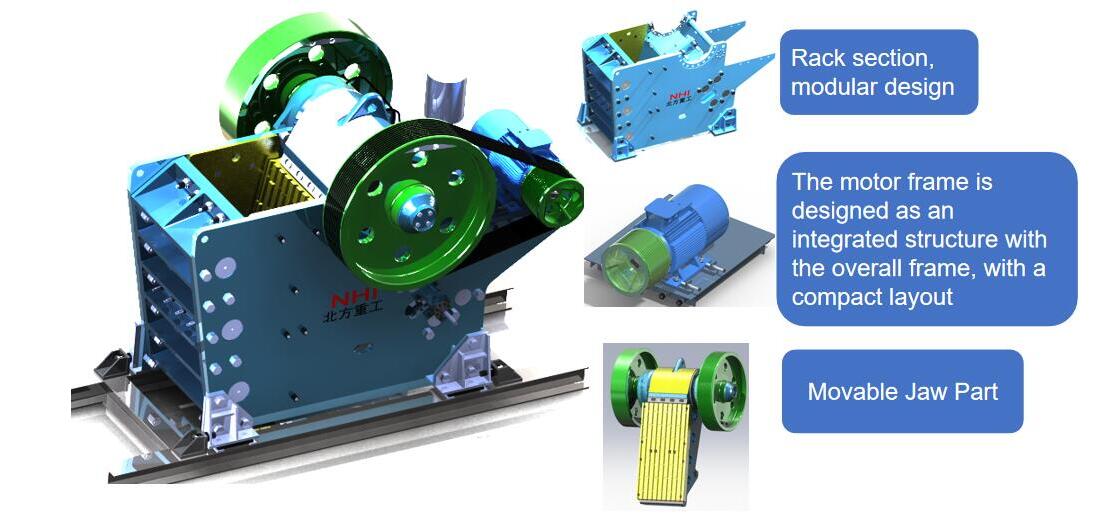

A tough Jaw Crusher Machine lasts longer and breaks less. Look for these strong parts:

- Fixed jaw plate made from high manganese steel

- Movable jaw plate on a sturdy swing jaw

- Eccentric shaft made of strong steel

- Toggle plate that keeps the machine safe

- Good bearings for smooth movement

Other design features that make it stronger:

- Bolted design lowers stress

- Heavy flywheels keep crushing steady

- Deep jaw gives better action

- Deflector and cheek plates add protection

Maintenance

You must keep your Jaw Crusher Machine working well. Do these steps:

- Check oil and worn parts every day.

- Lubricate parts once a week.

- Service the machine each month or quarter.

Common problems are noise, low output, hot bearings, and shaking. Regular checks and a set schedule help stop breakdowns.

Safety first: Always use lockout/tagout before fixing the machine. Never take off guards when the machine is running.

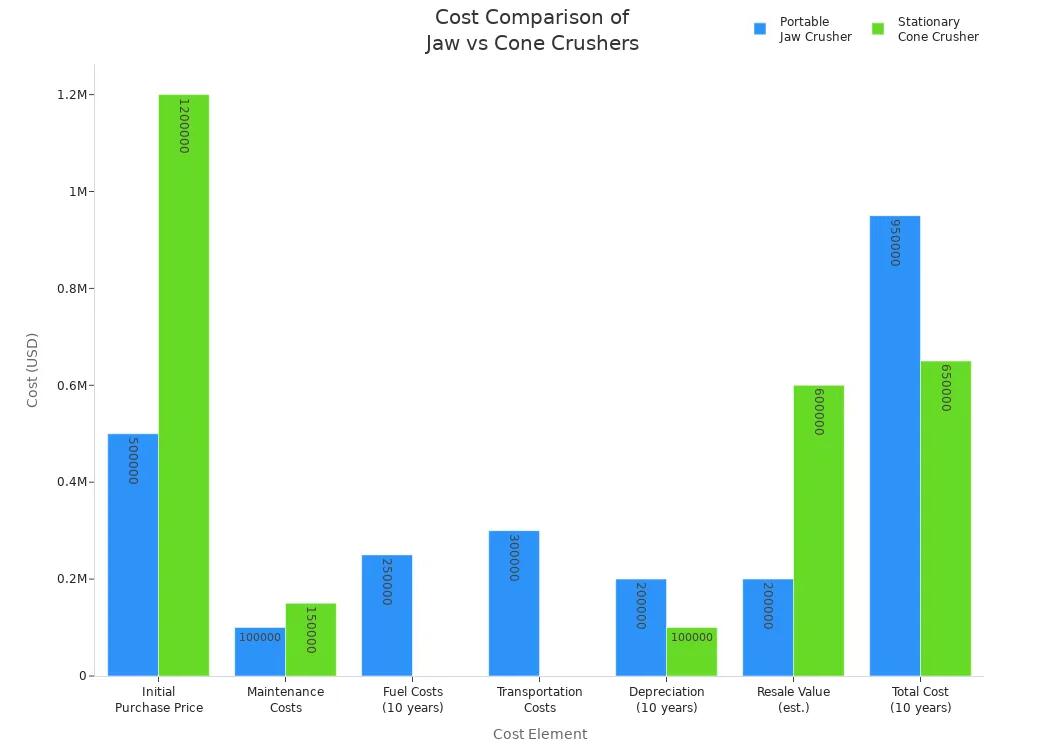

Stationary vs. Portable Options

Pick stationary or portable Jaw Crusher Machine types based on your site and budget.

Cost Element Portable Jaw Crusher ($) Stationary Cone Crusher ($) Initial Purchase Price 500,000 1,200,000 Maintenance Costs 100,000 150,000 Fuel Costs (10 years) 250,000 – Transportation Costs 300,000 – Depreciation (10 years) 200,000 100,000 Resale Value (est.) 200,000 600,000 Total Cost (10 years) 950,000 650,000

- Portable crushers are more flexible and cost less at first. They cost more to run.

- Stationary crushers cost more at the start. They save money over time and sell for more later.

3. Compare Models & Brands

When you look at Jaw Crusher Machine models and brands, you want the best one for your project. You should check if the machine is reliable. You should also look at the warranty, support, and what other people say.

Reliability

You need a machine that works well every day. Brands like NHI, Metso, and Sandvik are known for making strong machines. NHI is special because its machines last a long time. These brands help your project run with less stopping. Many people say models like the C6X crush more each day. They keep working well even when things get tough.

Tip: Read stories and reviews to learn how each brand does in real projects.

Warranty & Support

A good warranty helps you feel safe. Top brands give long warranties and help you anytime. Here is a table that shows this:

Warranty Period Support Type Additional Notes Up to 5 years 24/7 support Longer warranties can make your machine worth more. They use original parts for fixing.

- Some warranties last up to five years.

- You can get help any time, day or night.

- Good warranties help you plan repairs and make your machine worth more.

You should see if the warranty can go to a new owner. This can help you sell your machine for more money later.

User Feedback

User feedback shows how a Jaw Crusher Machine works in real life. Here are some things people talk about:

Feedback Theme Description Productivity Plants say they crush more after getting new machines. Cost Savings New machines cost less to run and pay off faster. Maintenance Machines need fixing less often, so there is less stopping. Adaptability Machines work well in many places, even if it is dusty or hot. Consistency People say machines work the same, even with lots of work. You should also think about the environment. Brands like Metso and Sandvik try to save energy and make less waste. New features, like hydraulic adjustment and safer platforms, make machines safer and better to use.

4. Budget & Costs

Cost & Value

When you choose a heavy-duty jaw crusher, you need to look at more than just the price tag. Here are key cost factors:

- Purchase Price: Heavy-duty jaw crushers cost more at first because they use strong materials and powerful motors.

- Operating Costs: You will spend money on energy and labor since these machines run often.

- Maintenance Costs: Regular checks and spare parts keep your crusher working. High-quality brands like NHI use better materials, which can lower your long-term expenses.

- Total Cost of Ownership (TCO): TCO includes the purchase price, maintenance, energy use, and even resale value. Sometimes, a cheaper machine costs more over time if it breaks down or uses more power.

Tip: Always compare TCO, not just the upfront price. A higher initial cost can save you money in the long run.

Operating Expenses

Operating expenses change based on the size of your jaw crusher and how you use it. Bigger machines cost more to install and move. Energy and fuel costs go up with larger models. If you use your crusher for tough jobs, you may need more repairs and parts. You should check these costs before you buy.

Financing

You have many ways to pay for your jaw crusher. Here are common options:

Financing Option Description Loans Borrow money from a lender to buy the equipment. Leasing Rent the crusher for a set time, with a chance to buy it later. Hire Purchase Agreements Pay in parts while using the crusher. You own it after the last payment. Vendor Financing Get financing from the seller, often with special terms. Lines of Credit Use flexible funds as needed for your purchase. Note: Hire purchase agreements help you manage cash flow. You pay in steps and own the machine at the end.

5. Final Selection Steps

Selection Checklist

Before you make your final choice, you should go through a checklist. This helps you avoid missing important details. Here is a list of items you need to check on your jaw crusher machine:

- Jaw Plates: Look for wear and decide if you need replacements.

- Bearings: Inspect for any play or damage.

- Toggle Plate and Toggle Seat: Make sure they are aligned and not worn out.

- Eccentric Shaft: Check for misalignment or damage.

- Flywheel: Look for balance and signs of wear.

- Hydraulics: Test for leaks and proper pressure.

- Drive System: Check the motor, belts, and pulleys for tension and alignment.

- Clearance and Adjustment: Confirm all settings and test adjustment mechanisms.

- Electric: Inspect wiring, switches, and control panels.

- Safety Items: Make sure guards and emergency stops work.

- Functional Test: Run a test with material to see how the machine performs.

Expert Advice

You should talk to experts before you buy. They can help you avoid common mistakes. Here is a table that shows mistakes and how to avoid them:

Factor Explanation Production capacity Pick the right size to avoid delays or wasted money. Equipment quality Choose strong materials to lower repair costs. Material properties Match the machine to your material for better results. Local environmental policy Follow rules to avoid fines and pollution. Tip: Experts from NHI can guide you through each step and help you match the crusher to your project.

Site Testing

You should test the jaw crusher at your site before you buy. This lets you see how it works with your material and setup. You can check for noise, output, and safety. A site trial helps you find problems early and make sure the machine fits your needs. If you test first, you can avoid costly mistakes and get better results for your project.

Picking the right jaw crusher helps you in many ways. You can choose a machine that fits your material’s size and amount. This makes the work easier and faster. You save money and get better results. You also follow safety and environmental rules.

Regulation Type Description Emissions Compliance Machines must follow EPA engine rules. Dust and Particulate Control Use water or dust control to keep air clean. Community Notifications Let people nearby know before using big machines. Make a checklist and ask experts for help before you buy. This helps you pick the best machine and get good results.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported