When you look for heavy duty jaw crushers, you should notice the most important features.

-

Automation and real-time monitoring help you work faster and stop less often.

-

Energy-efficient designs help you spend less money and are better for the environment.

-

Strong build and durability mean you fix them less and they last longer.

-

Safety features keep workers safe and help you follow the rules.

Knowing these features helps you pick the best crusher for mining, building, or recycling. New options, like AI integration and noise reduction, can make your work easier and more effective.

Key Takeaways

-

Look for automation and real-time monitoring in jaw rock crushers. These features help you work faster. They also help reduce downtime.

-

Pick energy-efficient models to save money. These models also help the environment. This choice is good for your budget and the planet.

-

Choose strong build quality and durability. A well-built crusher lasts longer. It needs fewer repairs. This saves you time and money.

-

Make sure safety features are included. Modern crushers have systems to protect workers. They also lower the risk of accidents.

-

Regular maintenance is important. Simple tasks like lubrication and inspections help your crusher run well. They also make it last longer.

Jaw Rock Crushers Features

Crushing Performance

You want jaw crusher crushing equipment that works well every day. Crushing performance depends on a few things. These include throughput, energy use, and downtime. You should check how much material the machine can crush each hour. Throughput tells you how many tons you can crush without using more fuel or power. Energy use is important because new wear parts and good lubrication save power. This lowers your costs and cuts down on emissions. Downtime means how often the jaw crusher stops for repairs or maintenance. Less downtime means you can crush more and stop less.

Tip: Keep track of these numbers. This helps your crushing equipment run smoothly and stops surprises.

|

Metric |

Description |

|---|---|

|

Throughput |

A better jaw crusher crushes more tons per hour without extra fuel or power. |

|

Energy use |

New wear parts and good lubrication save power, lowering costs and emissions. |

|

Downtime |

Bad crushers show poor maintenance, causing stops and expensive repairs. |

Different jaw crusher models have different capacities and reduction ratios. For example, the Metso C160 model can handle up to 1,145 mtph (scalped) and up to 1,909 mtph (non-scalped). Its reduction ratio is up to 20% higher than other models. The Metso C150 model has less capacity and a lower reduction ratio. Most jaw rock crushers use pressure to break hard materials. A normal reduction ratio is 6:1. This means the crusher makes the material six times smaller during primary crushing.

|

Model |

Maximum Capacity (mtph) |

Scalped Feed (mtph) |

Reduction Ratio |

|---|---|---|---|

|

Metso C160 |

1,145 (scalped) |

1,909 (non-scalped) |

Up to 20% higher |

|

Metso C150 |

880 (scalped) |

1,319 (non-scalped) |

Lower than C160 |

Durability And Build

Durability is very important when picking jaw crusher crushing equipment. You want a machine that lasts a long time and can do hard jobs. The design of the jaw crusher matters a lot. Manufacturers use strong materials and smart designs to make the crusher last longer. Putting the crusher on a flat, stable base stops too much shaking. Vibration pads help lower stress during use. Always check if the parts are lined up right to avoid problems.

Note: Pick jaw rock crushers made for your materials. Do not crush things that are too hard, wet, or the wrong size. This lowers stress and helps the crusher work better.

Doing regular maintenance keeps your jaw crusher strong. Lubrication cuts down on friction and wear. Inspections help you find damage or loose parts early. Cleaning the crusher and area stops clogs and helps it work better. Keeping belts tight and lined up stops extra wear. Using sensors lets you watch performance and find problems before they get worse.

|

Maintenance Practice |

Description |

|---|---|

|

Lubrication |

Needed to cut friction and wear; follow the maker’s advice for type and how often. |

|

Inspection |

Check often for wear, damage, or loose parts to stop bigger problems. |

|

Cleaning |

Keep the crusher and area clean to stop clogs and help it work better. |

|

Belt tension and alignment |

Make sure belts are tight and lined up to stop extra wear and damage. |

|

Monitoring |

Use sensors to watch performance and find problems early. |

Adjustability And Versatility

You need jaw crusher crushing equipment that can do many jobs. Adjustability lets you change the output size by moving the closed-side setting (CSS). This helps you handle different feed sizes and types of material. The design of jaw plates and how you feed the crusher also matter. A good feed means the material is bigger than the CSS but not bigger than 80% of the feed opening. This gives you the best crushing and capacity.

-

Jaw rock crushers can change the closed-side setting to control output size for different feed sizes.

-

The design of jaw plates and feeding methods affect how the crusher handles different materials.

-

A good feed is important. The material should be bigger than the closed-side setting but not more than 80% of the feed opening.

Some jaw crusher models are very flexible. You can use them for mining, building, or recycling. For example, the Rebel Crusher from R.R. Equipment Co. can crush up to 140 TPH and uses a 240 HP engine. The Komplet K-JC 604 Mobile Jaw can crush up to 55 TPH. The Komplet K-JC 503 Mobile Mini can crush up to 34 TPH. These models work in many places and make your crushing equipment more useful.

|

Model |

Brand |

Capacity (TPH) |

Weight (Lbs) |

Engine Type |

|---|---|---|---|---|

|

Rebel Crusher |

R.R. Equipment Co. |

Up to 140 |

38,000 |

240 HP |

|

Komplet K-JC 604 Mobile Jaw |

Komplet America |

Up to 55 |

19,400 |

Doosan Tier 4 Final |

|

Komplet K-JC 503 Mobile Mini |

Komplet America |

Up to 34 |

7,496 |

Kubota Stage V |

Safety And Ergonomics

Safety is very important when using jaw crusher crushing equipment. Modern jaw rock crushers have hydraulic chamber clearing systems. These open the crusher to a safe spot so materials can pass through. Hydraulic overload relief protects parts from damage. Hydraulic adjustment stops downtime from manual changes and keeps output safe and steady.

|

Safety Feature |

Description |

|---|---|

|

Hydraulic Chamber Clearing System |

Opens the crusher to a safe spot, letting materials pass. |

|

Hydraulic Overload Relief |

Protects parts from overload damage. |

|

Hydraulic Adjustment |

Stops downtime from manual changes, keeping output safe and steady. |

Ergonomic features make daily use easier. Big hydraulic cylinders make things safer and need less manual work. Push-button controls let you change the closed-side setting without shims, lowering accident risk. Safe toggle maintenance means you do not go under the jaw until it is safely lowered.

|

Ergonomic Feature |

Description |

|---|---|

|

Oversized Hydraulic Cylinders |

Make things safer and need less manual work. |

|

Push-Button Controls |

Let you change the closed-side setting easily, lowering accident risk. |

|

Safe Toggle Maintenance |

You do not go under the jaw until it is safely lowered, making it safer. |

Alert: Always wear PPE like hard hats, safety glasses, vests, hearing protection, boots, and gloves. Lockout/Tagout steps are needed for safe maintenance.

Safety features in jaw crusher crushing equipment help stop accidents and injuries. Hydraulic systems do some jobs by themselves, lowering risks. Automatic clearing stops manual work during blockages. Hydraulic overload relief protects against broken parts.

|

Safety Feature |

Benefit |

|---|---|

|

Hydraulic toggle plate |

Releases pressure during tramp events, so you do not need to step in. |

|

Automatic clearing mechanisms |

Lets the crusher clear itself, keeping workers away from danger. |

|

Hydraulic overload relief system |

Opens the crusher if forces are too high, stopping damage. |

|

Push-button closed-side setting |

Makes changes easy and safe, lowering accident risk. |

-

Modern crushers clear themselves, so you do not need to step in.

-

Hydraulic overload relief opens the crusher if forces are too high, stopping damage.

-

Push-button controls for closed-side setting make changes easy and safe.

Maintenance And Usability

You want jaw crusher crushing equipment that is simple to use and care for. Jaw crushers are easy to use because of their simple structure and reliable work. Daily jobs include checking belts, guards, and safety devices, looking at lubrication, and greasing bearings. You should look for loose bolts, worn liners, or cracks. Clean away dust and blockages. Listen for strange vibrations to find problems early.

|

Maintenance Frequency |

Tasks |

|---|---|

|

Daily |

Check belts, guards, and safety devices. Look at lubrication and grease bearings. Look for loose bolts, worn liners, or cracks. Clean dust and blockages. Listen for strange vibrations. |

|

Weekly/Monthly |

Check jaw dies for wear and change settings. |

|

Seasonal/Annual |

Change worn liners, flush systems, check controls, inspect structure, check dust control. |

Easy-to-use features help with daily work and care. You can watch performance numbers to find problems and fix them fast. Numbers like throughput and vibration show how the crusher is working. Making changes based on these numbers helps the crusher work better. Watching balance and alignment stops problems and helps with daily care.

-

Jaw crushers are easy to use and care for because of their simple structure.

-

They work well and cost less to build, making them a top pick in many industries.

-

Watching performance numbers helps you find problems and keep things running well.

-

Numbers like throughput and vibration show how the crusher is working, so you can make changes fast.

-

Making changes based on these numbers helps the crusher work better.

-

Watching balance and alignment stops problems and helps with daily care.

Tip: Doing regular care and watching performance helps you crush better, stop less, and make your jaw crusher crushing equipment last longer.

Jaw Crusher Manufacturers

If you want a jaw crusher, you should know who makes the best ones. The jaw crusher market is getting bigger every year. In 2023, it was worth $1.99 billion. Experts think it will grow by 3.7% each year and reach $2.56 billion by 2030. There are many brands, but some are better because of their technology and service.

Leading Global Brands

There are some top brands in the jaw crusher market. These companies are known for good jaw crusher technology and strong products:

-

Metso – Makes jaw crushers that work well and are powerful.

-

Sandvik – Builds quality machines and cares about the environment.

-

Terex Corporation – Makes tough jaw crushers and wants customers to be happy.

-

Thyssenkrupp AG – Is known for new ideas and strong machines.

-

SBM – A big Chinese company with good equipment.

-

Astec Industries – Uses new jaw crusher technology and cares about the planet.

-

McCloskey International – Makes mobile jaw crushers.

-

Eagle Crusher – Builds jaw crushers you can move easily.

-

McLanahan Corporation – Designs special jaw crushers for different needs.

-

ZENITH – A top Chinese company in mining machines.

These brands are well-known in the jaw crusher market. They spend money on research to make jaw crushers better. You get new control systems, stronger parts, and energy-saving features.

Regional Key Players

Some jaw crusher makers focus on local markets. In North America, Lippmann-Milwaukee, Terex Corporation, and Astec Industries make jaw crushers with easy spare parts. In Europe, FLSmidth, Keestrack, and Komatsu Europe have jaw crushers for many jobs. In Asia-Pacific, SBM, Zhejiang Zhekuang, and Puzzolana make jaw crushers that cost less. Latin America has Furlan and Talleres Núñez. Africa and the Middle East have Osborn and Pilot Crushtec.

|

Region |

Manufacturer Examples |

Unique Features |

|---|---|---|

|

North America |

Lippmann, Terex, Astec |

Spare parts are easy to get and install. |

|

Europe |

FLSmidth, Keestrack, Komatsu |

Good service and special solutions for customers. |

|

Asia-Pacific |

SBM, Zhekuang, Puzzolana |

Lower prices and can make lots of crushers. |

|

Latin America |

Furlan, Talleres Núñez |

Made for local rocks and weather. |

|

Africa & ME |

Osborn, Pilot Crushtec |

Strong support and tough machines for hard jobs. |

Local companies help you find jaw crushers that fit your area. They give fast help and know what you need.

What Sets Them Apart

You might wonder what makes each jaw crusher maker different. The best brands work on new ideas, good support, and smart designs. For example, Metso gives you new control systems. Sandvik spends money on research. McLanahan has new jaw crusher ideas and great help for customers. Thyssenkrupp works with others and is a big name in the market.

Local companies are special because they can change jaw crushers to fit your job. They help you pick the right jaw crusher. Good support means your jaw crusher works more and breaks less. You save money because spare parts are easy to get and you can sell your jaw crusher for a good price later.

Tip: Pick a jaw crusher maker with good support, easy care, and the newest jaw crusher technology. This helps you get the most for your money in the jaw crusher market.

Jaw Crusher Market Offerings

Popular Models Overview

There are many jaw crusher models you can buy. Some are strong and crush rocks well. The X250 model is tough and can be upgraded. It works great for mining and hard jobs. The YZB380 model uses new technology and automatic controls. You can use it for many materials and get good results.

|

Model |

Features |

Advantages |

|---|---|---|

|

X250 |

Strong build, high crushing power, easy upgrades |

Used a lot in mining jobs |

|

YZB380 |

New tech, automatic settings |

Works with many materials |

PE jaw crusher models are simple to use and easy to fix. Tracked jaw crushers move easily and have remote controls. You can use tracked crushers for short jobs or if you need to move them often. The Komatsu BR380JG-1E0 jaw crusher crushes 50 to 240 tons each hour. It has hydraulic protection to stop long breaks.

Small Portable Jaw Crusher Options

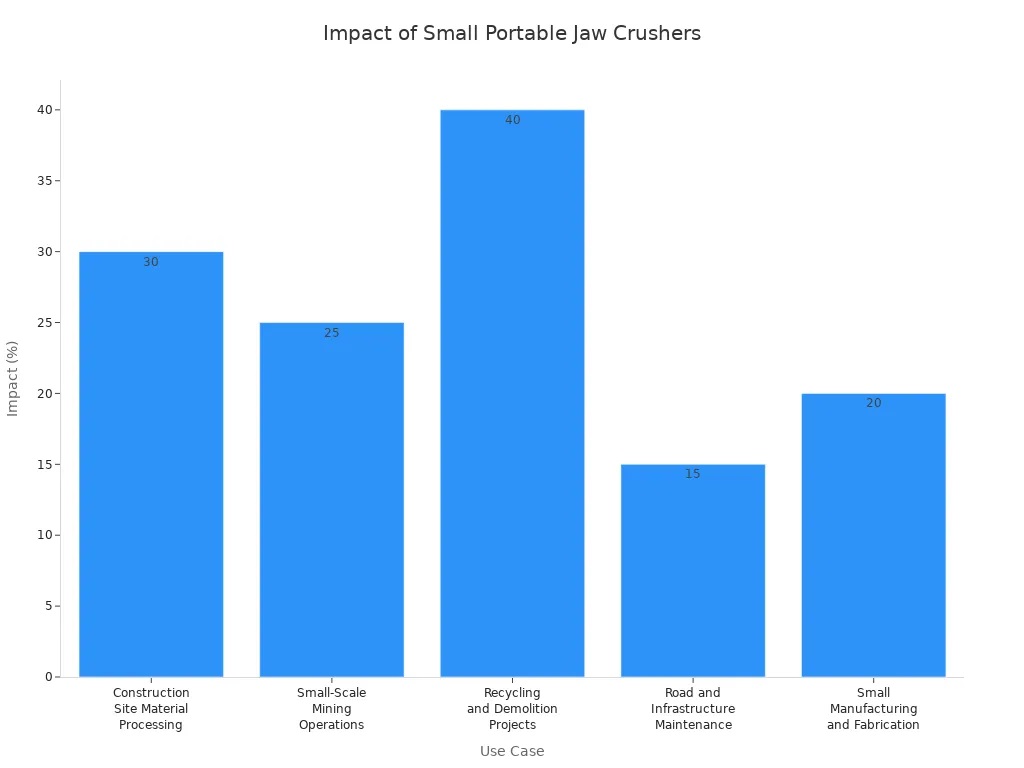

You might need a small portable jaw crusher for tight places or quick jobs. These crushers help you crush things where you work and save money. You can use a small mobile jaw crusher for building waste, mining, or recycling. The Terex EvoQuip Bison 120 crushes up to 80 tons each hour. The Bison 35 is very small and good for small companies. The Dragon CR400 and CM CR 600 work well in cities and green projects.

|

Use Case |

Description |

Example Impact |

|---|---|---|

|

Construction Site Material Processing |

Crushes concrete and asphalt at the site, saving money and cutting waste. |

A mid-sized company saves 30% on disposal costs. |

|

Small-Scale Mining Operations |

Good for first ore crushing in small mines. |

A regional mine gets 25% better ore processing. |

|

Recycling and Demolition Projects |

Turns waste into new materials, good for cities. |

A city recycling center boosts throughput by 40% with a compact crusher. |

|

Road and Infrastructure Maintenance |

Makes crushed material for road repairs at the site, saving time and money. |

A city project in Europe is 15% faster. |

|

Small Manufacturing and Fabrication |

Lets companies crush raw materials themselves, so they buy less from others. |

A regional maker cuts raw material costs by 20%. |

You can pick a small mobile jaw crusher if you want to move it easily and set it up fast. A small hydraulic jaw crusher is safe and strong, and you do not need to do much by hand.

Price And Value

You probably want to know what a jaw crusher costs. Prices change with size, power, and features. Mobile jaw crushers take big rocks and make a lot of crushed material. Here are prices for some popular models.

|

Model |

Price (USD) |

|---|---|

|

2022 Barford 750J |

$279,900 |

|

2022 EVORTLE CT535 |

$120,000 |

|

2005 EXTEC C12 |

$179,900 |

|

2019 Red Rhino 7000 PLUS |

$129,900 |

|

2023 Red Rhino 7000 PLUS |

$159,900 |

|

2011 RED RHINO 2000 |

$19,000 |

Tracked mobile crushers cost more because they have more parts. Wheeled mobile crushers cost less but do not move as easily. Direct diesel-hydraulic crushers are cheapest and easy to care for. Diesel-electric crushers save fuel but cost more at first. Fully electric jaw crushers are quiet, make no emissions, and cost less to run.

Note: Crushers that take hours to set up are good for long jobs. For short jobs, pick a small mobile jaw crusher that sets up quickly.

User Reviews And Feedback

Many people say jaw crushers help them work faster and save money. One person said, "Using an SBM jaw crusher cut my downtime a lot, even with hard granite. It is easy to fix, and I crush more now." Experts agree jaw crushers are important for mining and building. You can trust these machines to break big rocks into smaller pieces. The Komatsu BR380JG-1E0 jaw crusher is special because it has hydraulic protection and works well in tough jobs.

A small hydraulic jaw crusher is safe and easy to use. A small mobile jaw crusher moves quickly and sets up fast. Many people like small portable jaw crushers for working at the job site.

When picking jaw rock crushers, look for the most important features. Experts say you should check for:

-

Strong build so it lasts longer and needs fewer repairs

-

High crushing power to help you get more work done

-

Settings you can change for different rocks and sizes

To pick the best jaw crusher, do these things:

-

Think about what you need, like the kind of rock, how small you want it, and how much you need to crush.

-

Find out about the types of crushers and what they do.

-

Look at different models to see which ones are strong, work well, last long, and are easy to fix.

You will get better results if you match the crusher’s features to your job. If you are not sure, ask sellers or look up more choices. The right jaw rock crushers will help you stay safe and finish your work faster.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported