Automation and digital control have transformed the operation of every tunnel boring machine. NHI has been at the forefront of this evolution in mining equipment by integrating smart systems and advanced sensors. The transition from manual labor to data-driven approaches in tunneling offers significant advantages.

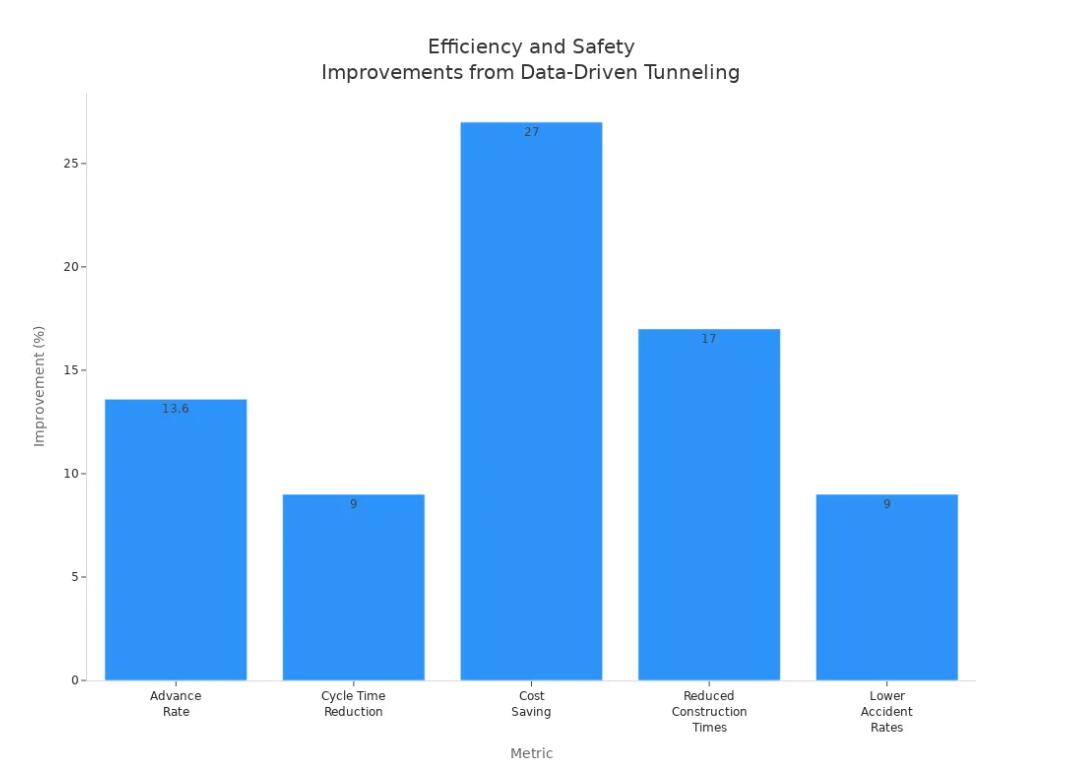

| Metric | Improvement |

|---|---|

| Advance Rate | 13.6% increase |

| Cycle Time Reduction | 9% reduction |

| Cost Saving | 27% total saving |

| Reduced Construction Times | 17% saving |

| Lower Accident Rates | 9% reduction |

Automation in Tunnel Boring Machines

Core Concepts of Automation

Automation is now very important in tunneling. In a tunnel boring machine, automation means using smart systems. These systems let the TBM work with little help from people. They use data from sensors and watch things in real time to make choices. The main ideas are:

- TBMs use AI and machine learning to change how they work right away.

- Automation helps pick the best digging settings, so it works better and uses less energy.

- These systems can change when the ground changes, so it is safer and there are fewer slowdowns.

NHI uses these ideas in its TBMs. This makes tunneling better and faster.

Digital Control Systems Overview

Digital control systems are the main part of automated TBMs. These systems gather and use data from many places. They get data from sensors in the machine and in the tunnel. The main subsystems are:

| Key Subsystems | Description |

|---|---|

| Modeling | Shows how the TBM might work in different cases. |

| Monitoring | Collects data right away to check how the TBM and tunnel are doing. |

| Control | Changes how the TBM works by itself to make it better. |

Digital tools and BIM help share data easily. This lets the TBM, managers, and repair teams work together. It helps people make good choices and keeps the work high quality.

From Manual to Automated TBMs

Moving from manual to automated TBMs changed tunneling a lot. Before, people used controls and looked at things themselves. Now, TBMs use automatic steering to move the machine the right way. This keeps the TBM on the planned path. It lowers the chance of mistakes and helps the project go well. Robots and BIM also help by moving tunnel pieces and fixing things before they break. Because of this, new TBMs work better, are safer, and do a good job during building.

Key Technologies Driving TBM Automation

Digital Twin and Real-Time Monitoring

Digital twin technology has changed how teams run a tunnel boring machine. It makes a computer copy of the real TBM. This copy connects to the control system using special rules like OPCUA. Operators use the digital twin to practice and learn in a safe place. The digital twin gets live data from sensors and parts. It helps teams watch pressures, speeds, and temperatures closely. This way, teams work more accurately and train better.

Real-time monitoring gives teams updates all the time. They can spot risks early and fix problems fast. This helps them make smart choices. Everyone involved can see what is happening. This makes people feel safer about the project. NHI uses digital twin and monitoring systems in its TBMs. This sets new rules for digital control in tunneling.

- Watching things all the time helps stop problems before they start.

- Live data helps teams choose the best actions.

- Sharing information builds trust with everyone.

AI for Path Optimization

AI path optimization uses smart computer programs to help TBMs work better. These programs, like Bayesian Optimization, CatBoost, and NSGA-III, look at tunneling data. They change how the shield is built to get better results. This makes tunneling faster and more efficient.

| Algorithm | Performance Improvement |

|---|---|

| Bayesian Optimization (BO) | Helps choose the best shield settings |

| CatBoost | Makes performance guesses more accurate |

| NSGA-III | Helps reach many goals at once |

| BO-CatBoost-NSGA-III | Makes TBMs over 25% better |

| Advancing Speed Improvement | 3.45% |

| Specific Tunneling Energy | 6.09% |

| Cutter Wear | 0.52% |

| Overall Reliability | 90.5% |

NHI leads by putting AI in its TBMs. These tools help TBMs work well even when the ground changes. This keeps the work safe and fast.

Automated Segment Handling

Automated segment handling uses robots and cameras to build and place tunnel parts. Robots work all day and night. This means fewer people are needed. The system can change to fit different jobs. This makes building faster and more exact.

- Robots can spot where to put parts over 90% of the time.

- Cameras find parts in about 0.7 seconds.

- The system can be changed to fit each project.

NHI’s segment handling systems are some of the best. They need less work from people, speed up building, and keep quality high.

Advanced Sensors and Data Collection

TBMs use advanced sensors to check things like torque, thrust, and power. Load cells, torque sensors, and other tools watch these numbers all the time. This helps the TBM change how it works right away. It keeps the machine safe and working well.

Live monitoring systems collect data about the TBM and the ground. Teams use this data to make quick choices and improve work. Watching things like cutterhead speed and thrust helps tunneling go smoothly.

NHI puts strong data systems and sensors in its TBMs. This helps everyone get the data they need.

Robotics in Tunnel Construction

Robotics are very important in tunnel building today. Robots do boring and risky jobs. This keeps workers safe and helps the project move faster. Using robots with digital tools means fewer mistakes.

- Robots can cut the number of workers in tunnels by 70%.

- Automated robots do jobs like putting up brackets, making things safer.

- Using robots and digital tools helps the environment and follows rules.

NHI’s work with robots and BIM is leading the way. Their systems make work faster, cheaper, and safer.

Note: NHI keeps using new digital tools, BIM, and digital control in tunneling. Their use of advanced technology, AI, and robots helps TBM projects reach top quality, speed, and safety.

Efficiency and Safety Impacts

Reducing Human Error

Automation has changed how teams build tunnels. Smart systems help control the cutter head and study the soil. Teams can make quick choices using live data. This lets them change boring settings when the ground changes. These changes lower mistakes and keep projects on track. Teams get better tunnel paths and safer work sites. Automation helps lower risks and keeps tunnel building steady. Projects finish faster and cost less. Automated tunnel boring machines are now more trusted.

- Autonomous TBMs finish building 20% faster.

- Predictive maintenance cuts TBM downtime by 15%.

- Drones and robots lower tunnel costs by 30%.

Enhancing Worker Safety

New tunnel projects use technology to keep workers safe. Robots and machines do dangerous jobs instead of people. This lowers the chance of accidents. Sensors watch air, temperature, and noise all the time. Teams can act fast if something is wrong. Smart helmets and vests warn workers in emergencies. Virtual reality helps workers learn about dangers in a safe way.

| Technology | Description |

|---|---|

| Real-time monitoring | Sensors check air, temperature, and noise to stop dangers. |

| Wearable devices | Smart gear tracks workers and warns them quickly. |

| Virtual and augmented reality | Training puts workers in fake tunnels to spot dangers. |

| Drones | Drones fly above and find unsafe spots or people. |

| Automated equipment | Machines do risky jobs so people stay safe. |

| Building Information Modeling | BIM finds safety problems early so teams can fix them. |

Micro TBMs have made job sites safer. AI systems can spot dangers before they happen. Automated safety controls can start emergency plans fast. NHI uses these tools to make tunnel building safer.

Improving Project Outcomes

Automation and digital tools help tunnel projects do better. TBMs with automation control their position more exactly. The system predicts tunnel path changes with scores of 0.86 and 0.92. TBM path control is now 50.7% better. BIM and digital tools help teams work safer and smarter. Scheduling software helps plan shifts so workers are less tired. Data from TBMs helps teams make good choices and check quality. These tools help tunnels last longer and work better.

Automation in tunnel boring machines makes building safer and healthier. AI and automation lower risks with safety training, live hazard checks, and robot helpers.

NHI leads by using BIM, robots, and smart controls. This helps make tunnel projects safe, strong, and fast.

Integration with Tunnel Innovations

Advanced Materials and Machine Design

Modern tunneling uses new materials and smart machine designs. These changes help teams build tunnels faster and better. Automation and robots move materials and do repairs. This keeps workers safe and helps work go quickly. Digital twin technology makes a computer copy of the tunnel boring machine. It helps teams plan and improve their work.

- Teams pick new materials to make machines light and strong.

- Robots and automation keep people away from dangerous jobs.

- Digital twin models let engineers try ideas before building.

Engineers use Graph-ConvNet, which mixes Graph Neural Networks and Convolutional Neural Networks. This system guesses how the machine will work by looking at data as a time graph. It finds important details and makes predictions more accurate. These new tools show how machine design and automation help tunneling get better.

Digital Project Management Tools

Digital tools have changed how teams run tunnel projects. BIM is a very important tool for building tunnels. It makes a 3D picture of the tunnel so teams can see how things fit. BIM helps teams spot safety problems early and plan well.

| Evidence Type | Description |

|---|---|

| Digital Twin Creation | BIM lets teams make a 3D tunnel model to see it better. |

| Early Issue Identification | Digital models help teams find safety problems early. |

| Improved Project Progress | BIM helps teams finish projects faster. |

| Cost Control | BIM helps teams keep track of costs. |

| Risk Reduction | BIM helps lower risks when building. |

| Safety Management | Machine learning with BIM helps watch safety in real time. |

| Predictive Capabilities | Machine learning helps teams stop safety problems before they happen. |

NHI uses these tools to keep building safe, quick, and on time.

Seamless Communication and Lifecycle Management

Good communication helps tunnel projects succeed. Teams use a Common Data Environment to share info fast. This system helps update designs and makes calculations quicker. Everyone gets the latest data, so decisions are made faster and projects do better.

- The Bergünerstein Tunnel project used this system for easy data sharing.

- Having all info in one place helped teams talk and decide quickly.

- Lifecycle management makes sure every step of building is good for the planet and high quality.

NHI uses these new systems and digital tools in every part of tunnel building.

Future Trends in Tunnel Automation

AI and Machine Learning Advances

AI and machine learning are changing how tunnels are built. Engineers use deep learning to check rock conditions without doing it by hand. Clustering algorithms help teams find rock features fast. Building information modelling works with machine learning and robots to make building safer and faster. Predictive algorithms use sensor data to watch the TBM in real time. This helps the TBM work better and stay steady. The SVM model can guess rock problems with 98.56% accuracy. This lets teams change what they do right away. FANUC ROBOGUIDE helps move materials exactly, so there are fewer risks and delays. The XGBoost model finds what affects shield control. This helps teams make changes for better tunneling.

| Technology/Method | Description | Impact |

|---|---|---|

| BIM Integration | Combines building information modelling with robotics | Improves construction efficiency and safety |

| SVM Model | Predicts geological challenges | Enables real-time operational adjustments |

| FANUC ROBOGUIDE | Precise material handling | Reduces risks and delays |

| Predictive Algorithms | Real-time sensor data monitoring | Enhances TBM performance |

| Deep Learning Techniques | Automates rock mass assessment | Improves geological accuracy |

Increasing Automation Levels

Tunnel boring machines are getting more automated. In 2024, there were both semi-automated and fully automated systems. Fully automated TBMs grew the fastest because of new technology and more people trusting automation. Experts think automated solutions will grow by 8.7% each year from 2025 to 2033. Rules and the need for easy repairs help this growth.

| Year | Automation Level | Market Growth Rate | Key Drivers |

|---|---|---|---|

| 2024 | Semi-automated | N/A | Regulatory requirements, budget constraints |

| 2024 | Fully automated | Highest growth rate | Technological advancements, automation demand |

| 2025-2033 | N/A | 8.7% CAGR | Demand for automated solutions in construction |

Now, fully automated subsystems do jobs like putting in segments and taking out materials. Laser-based systems help the TBM move without people. This makes work faster and easier. Data systems save billions of data points. This helps teams make choices right away.

The Future of Digital Tunneling

Digital tunneling will keep getting better. Researchers made digital twin frameworks for subway tunnels. Early-warning platforms from mining now help teams handle tunnel risks. AI and multi-index frameworks make machine learning better for building. Deep learning is used in seven main areas of tunnels and underground work.

- Digital twin frameworks help teams manage tunnels for a long time.

- Early-warning platforms let teams act fast when there are risks.

- AI and machine learning help teams control and fix things better.

Modern TBM teams use real-time data and smart algorithms to guess what will happen and make tunneling better. NHI leads by using these new ideas in their projects. This sets new rules for safety, speed, and quality.

Automation and digital control have changed how tunnel boring machines are built. Teams use live data and smart systems to work faster and safer. The table below shows how these tools help construction:

| Technology | Benefit for Construction |

|---|---|

| Automation and digitalization | Big projects get done more quickly |

| AI and robotics | Building is safer and works better |

| BIM integration | Planning and control are easier |

| Predictive maintenance | There are fewer slowdowns during building |

Experts think AI, robotics, and self-running machines will help every step of building. NHI leads by using these new tools. Teams should learn about these changes and use smart automation to get better results.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported