To choose the best Long Distance Belt Conveyor in 2025, start by assessing your project requirements. Make sure the features of the long distance belt conveyor align with your operational goals. Look for energy-efficient motors, durable materials, and advanced automation in your belt conveyor selection. Consider the volume of material you need to transport, the terrain, and the type of bulk material equipment required. Industry reports indicate that the belt conveyor market is projected to reach USD 8.2 billion by 2034.

- The conveyor system market is expected to hit USD 10.94 billion in 2025.

Key Factors for Long Distance Belt Conveyor Selection

Defining Project Goals and Requirements

First, think about what you want your conveyor to do. Each project is different, so set clear goals. These goals can be things like making work safer, working faster, or getting ready for future changes. The table below lists common goals and needs for long distance belt conveyor projects in 2025:

| Project Goals/Requirements | Description |

|---|---|

| Safety Enhancements | Conveyor systems must be very safe and follow rules to protect workers and lower risks. |

| Efficiency Optimization | Systems should carry lots of material and still work well. |

| Life Cycle Cost Consideration | Saving money over time is more important than just picking the cheapest system. |

| Compliance with Regulations | Designs must follow all laws and rules to work legally and safely. |

| Future Capacity Accommodations | The first design should let you add more later without spending a lot. |

| Maintenance Accessibility | Systems should be easy to fix and keep working safely. |

Setting your main goals helps you pick the right conveyor. For example, you need to know how much material you will move now and later. This helps you choose the right size and if it can grow with your needs. Your budget matters for buying and fixing the conveyor. If you want to grow, pick a conveyor that can change as you do.

Think about how much it costs to own the conveyor, not just to buy it. This means you look at how much it costs to run and fix over time. Sometimes, paying more at first saves money later because the system works better and needs fewer repairs.

Material and Product Characteristics

The kind of material you move is very important when picking a long distance belt conveyor. You need to check things like how heavy it is, how big it is, what it feels like, and if it is wet. These things change how the conveyor works and how long it lasts. Here is a table with some important points:

| Factor | Description |

|---|---|

| Tensile Strength | Shows if the conveyor can hold heavy loads and stay strong. |

| Material Composition | Different materials like rubber, fabric, or steel make the belt strong or flexible. |

| Belt Design and Ply Structure | How thick and how many layers the belt has affects how it carries weight and lasts. |

| Environmental Conditions | Sun, heat, and chemicals can hurt the belt over time. |

You also need to think about how the material’s weight, size, and wetness will change the conveyor:

- Heavy things need strong conveyors.

- Fragile items need gentle moving so they don’t break.

- Wet things can stick to the belt and block it. You might need special cleaning tools to keep it working.

- Things that don’t flow well may need extra equipment to stop jams.

If you move sticky or wet stuff, you might get problems like clogs or piles. These can slow down your work and make you fix the conveyor more often.

Throughput, Distance, and Terrain

How much you move, how far it goes, and the ground it crosses all matter when picking your conveyor. These things change how you build and pay for your long-distance belt conveyor. The table below shows how different things can change your choice:

| Factor | Influence on Engineering and Cost |

|---|---|

| Terrain Complexity | Hard ground makes building harder and costs more, so you need to change the design. |

| Route Selection | Picking the best path saves money and helps the conveyor work better. |

| Component Arrangement | You need to think about where power and repair spots go, which makes the design harder. |

| Environmental Considerations | You may need to make the conveyor quieter near homes, which changes the design. |

If your conveyor goes over hills or rough ground, you might need special supports or new designs. Picking the best path can save money and make the system work better. You also need to plan for easy power and repair spots. Sometimes, you need to make the conveyor quieter, especially near houses or offices.

Customization and Environmental Needs

Every long-distance conveyor project is different. You may need to change the conveyor to fit your space, material, and environment. Some popular changes include:

| Customization Option | Description |

|---|---|

| Variable Speed Controls | Lets you change how fast the belt moves for better control. |

| Specialty Belt Materials | You can pick belts that are safe for food, resist heat, or stop static for special jobs. |

| Automated Control Integration | Works with sensors and machines to help manage the process. |

| Modular Design | Makes it easy to add or change parts as your needs grow. |

| Custom Dimensions | You can pick the length, width, and angle to fit your space. |

You might need stainless steel conveyors for clean rooms, food factories, or places with explosions. Special belts can handle hot or cold places. If you work outside, you need to protect the conveyor from sun, rain, and temperature changes. Sunlight can make belts weak, and chemicals can hurt parts. Fixing and protecting the conveyor helps it last longer.

Tip: Always pick conveyor materials and designs that match your environment. This stops breakdowns and keeps your work going.

When you think about these important things, you can pick a long distance belt conveyor that works for you now and can change as your project grows.

Comparing Long-Distance Conveyor Types

Major Conveyor Types Overview

There are many long-distance conveyor systems you can pick from. Each one has special features for different jobs. The table below lists the main types and what makes them different:

| Conveyor Type | Distinguishing Features |

|---|---|

| Roller Bed Belt Conveyor | Uses rollers to move heavy things fast with less friction. |

| Flat Belt Conveyor | Good for many products. It is easy to line up and best for slow lines. |

| Modular Belt Conveyor | Has pieces that lock together. It is strong and easy to clean. |

| Cleated Belt Conveyor | Has raised parts to stop items from sliding. It works well on slopes. |

| Incline/Decline Belt Conveyor | Moves things up or down between floors. It is good for places with more than one level. |

New designs like cable-hauled conveyors and RopeCon are now available. These new systems are more flexible and can go farther.

- Cable-hauled systems, like Cable Belt, can move things up to 31 kilometers in one trip.

- RopeCon uses both a ropeway and a conveyor belt to cross hard ground.

Suitability for Different Projects

You need to pick the right conveyor for your project. For building or mining, belt conveyors are best for moving lots of material far. Chain conveyors are strong and work well in cement or steel plants. Screw conveyors fit in small spaces and give good control. Bucket elevators lift things straight up in warehouses or grain silos.

| Conveyor Type | Advantages | Applications |

|---|---|---|

| Belt Conveyors | Move lots of material, can be changed, and run all the time | Mining, farming, building sites |

| Chain Conveyors | Very strong and need little fixing | Cement, steel factories |

| Screw Conveyors | Small, closed, and easy to control | Tight spaces |

| Bucket Elevators | Lift things up, work well | Warehouses, grain storage |

For steep hills or rough ground, sidewalls and cleats help keep things from falling off.

Pros and Cons of Each Conveyor

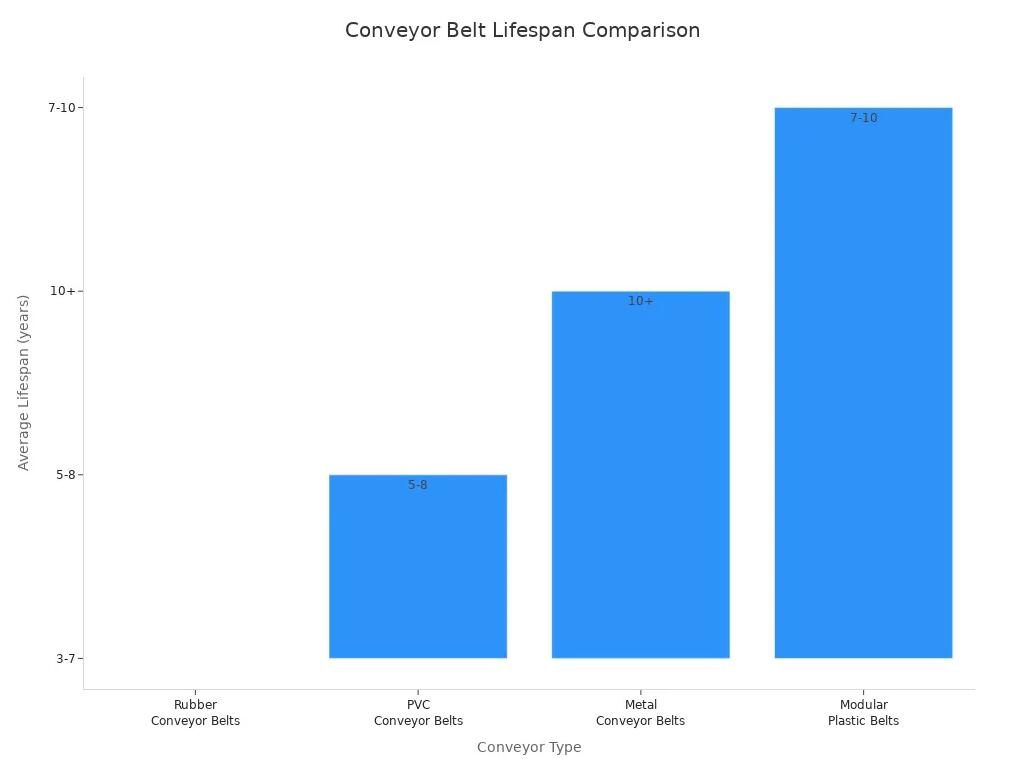

You should look at the good and bad sides of each conveyor. Rubber belts last 3-7 years and take hits well but wear out faster. PVC belts last 5-8 years and do not get hurt by chemicals but cannot take high heat. Metal belts last over 10 years and carry heavy things but can rust. Modular plastic belts last 7-10 years, do not rust, and are easy to clean but cost more at first.

Some types, like indexing conveyors, have limits on how fast they work and need more planning. Power and free conveyors are harder to design and are not as flexible. Dial tables move together but can slow down the work.

Tip: Always check how much fixing is needed and how long the conveyor will last before you choose one.

Selecting the Right Conveyor: Best Practices & Mistakes

Steps for Efficient Selection

You need to pick the best conveyor for your project. First, look at what kind of material you will move. If it is heavy or sharp, you need a strong conveyor. Next, think about how much you will move and how fast it must go. Check how far the conveyor will travel and the path it will take. Make sure the conveyor fits your space and follows safety rules. Plan for changes so your conveyor can grow with your company.

Here are some steps to help you choose well:

- Tighten the belt right so nothing spills out.

- Do not load the belt more than 75% to keep it smooth.

- Change idler angles to keep material in place.

- Clean the conveyor often so nothing builds up.

- Keep the belt dry so it does not slip or stick.

- Use cleaners to stop things from spilling.

- Add plates and pans to catch anything that falls.

Think about how much the conveyor costs over time, not just at first. Energy-saving conveyors help you save money later. Modular designs let you change the conveyor as your needs change.

Common Mistakes to Avoid

People sometimes make mistakes when picking a conveyor. The table below shows common mistakes and what happens if you make them:

| Mistake | Description |

|---|---|

| Improper pulley diameter selection | Small pulleys break more and need more fixing. |

| Lack of access for maintenance | Bad design makes repairs hard and slows down work. |

| Covering key components | Pipes can block parts and make repairs harder. |

| Insufficient edge sealing | Bad seals let dust and material spill out. |

| Poor chute design | Bad chutes cause jams and need more fixing. |

| Inadequate belt cleaning | Not cleaning enough makes more dust and spills. |

| Substituting speed for belt width | Picking speed over width makes it less efficient. |

| Failure to allow for upgrading | Not planning for upgrades stops you from growing. |

You can stop these mistakes by working with experts and thinking about what you will need later.

Future-Proofing Your Conveyor Choice

You want your conveyor to last and change with your business. Pick smart conveyors with tools to watch and control them. Choose modular conveyors you can change as your work grows. Make sure your conveyor works with your other machines. Top companies use new technology and designs that can grow. Getting help and service keeps your conveyor strong as your business gets bigger.

Tip: Always plan for upgrades and changes when you pick your conveyor. This helps your long distance belt conveyor work well for a long time.

Look at some important things before you decide:

| Checklist Item | Description |

|---|---|

| Belt Condition | Make sure the belt is not worn out or crooked. |

| Safety Mechanisms | Try out emergency stops and safety locks. |

Ask people who know a lot for help. Pick a conveyor that fits what you need now and later. This can help you spend less money over time.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported