You may wonder about the cone crusher price in 2024. The price can range from $50,000 to over $1,500,000, depending on the type and model. Here is a table that shows typical price ranges:

|

Cone Crusher Type |

Price Range (USD) |

|---|---|

|

HPT Multi-cylinder Hydraulic Cone Crusher |

$150,000 to $1,050,000 |

|

HST Single Cylinder Hydraulic Cone Crusher |

$80,000 to $1,500,000 |

|

CS Spring Cone Crusher |

$50,000 to $150,000 |

You should know that prices vary because of many factors. When you choose a crusher, always look at both the initial price and the long-term costs such as maintenance and energy use.

Key Takeaways

-

Cone crusher prices can be from $50,000 to over $1,500,000. You should think about the first price and future costs like fixing and upkeep.

-

Pick the right cone crusher for your project size. Basic models work well for small jobs. Expensive models are better for big mining projects.

-

Things like how much it can crush, the type, and new technology change the price. Bigger machines usually cost more but can make you more money later.

-

Watch the prices of raw materials, like steel. Steel prices can change the cost of cone crushers a lot. If steel is cheaper, you might get a better price.

-

Always think about what you need to crush before you buy. Make sure the crusher’s size and features fit your project for the best results.

Cone Crusher Price Range

When you shop for a stone crusher, you will see many prices. The cost of a cone crusher depends on its model, size, and features. Some machines work for small jobs. Others are made for big mining projects. There are three main types to look at.

Entry-Level Cone Crushers

Entry-level cone crushers are good for small or medium jobs. You can use them for mining, building, or recycling. These machines have spring systems that protect them from too much weight. They are simple to use and easy to fix. Beginners like these machines because they are not hard to learn.

Here is a table with features and prices for entry-level crushers:

|

Feature |

Description |

|---|---|

|

Cost-effective solution |

Made for small or medium jobs |

|

Reliable spring system |

Stops damage from too much weight |

|

Easy to maintain and operate |

Good for people new to crushers |

|

Versatile application |

Works for mining, building, and recycling |

|

Price Range |

$50,000 to $150,000 USD |

Entry-level cone crushers usually start at about $100,000. These machines let you begin without spending a lot of money.

Mid-Range Cone Crushers

Mid-range cone crushers are stronger and make more crushed rock. You can use them for bigger jobs that need more power. These machines cost around $500,000. The price changes if you want more capacity or special features.

How much a crusher can handle affects the price. If you pick a model with a bigger opening, it might not crush as much each hour. The right size helps the crusher work better. Faster speeds crush more rocks but can wear out parts. Hard or wet rocks also change how fast the crusher works.

Here is a table that shows what affects capacity and output:

|

Factor |

Influence on Capacity and Output |

|---|---|

|

Feed Size |

Bigger openings mean less crushed rock; right size works best |

|

Speed of Operation |

Faster speeds crush more but wear out parts |

|

Material Characteristics |

Hard or wet rocks slow down crushing |

When you look at mid-range crushers, think about these things to get the best deal.

High-End Cone Crushers

High-end cone crushers use new technology and work very well. Their prices can be $1 million or even more. These machines are made for big mines and tough jobs. They help you crush more rocks, save energy, and last longer.

Here is a table with high-end models and their prices:

|

Model Description |

Price Range |

|---|---|

|

Hot Sale 100 TPH Advanced Technology 3ft Cone Crusher |

$19,000 - $20,000 |

|

Combined Hydraulic Rock Cone Crusher Klc1380 |

$80,000 - $100,000 |

|

Japanese Technology Minyu Compound Hydraulic Rock Cone Crusher |

$80,000 - $100,000 |

|

Nice for Stone Crushing of The High Performance Compound Cone Crusher |

$80,000 - $100,000 |

|

Hpy Series Multi-Cylinder Hydraulic Cone Crusher |

$100,000 - $150,000 |

|

Iron Copper Ore/Granite/Gravel/Basalt/River Stone Rock Spring Stationary Symons |

$78,000 - $80,000 |

|

Kl Series Symons Combined Hydraulic Stone Cone Crusher for Aggregates Crushing |

$70,000 - $80,000 |

|

Good Quality Spring Cone Crushers |

$70,000 - $90,000 |

High-end cone crushers have special features that make them cost more. These features help you crush more rocks each hour. They use less energy and break down less often. Automation makes them easier to use and helps them work better.

Here is a table with important features and what they do:

|

Feature |

Benefit |

|---|---|

|

Improved Productivity |

Crushes more rocks each hour than basic models |

|

Energy Efficiency |

Uses less electricity, so you save money |

|

Reliability |

Strong parts mean fewer breakdowns and less lost time |

|

Low Operating Expenses |

Automation and tough parts mean less fixing and longer life |

|

Flexibility |

You can change settings fast and use with other machines |

|

Advanced Automation |

Makes the crusher easier to use and adjust |

Tip: When you compare cone crusher prices, look at features and size. You will get more for your money if you pick the right machine for your job.

Cone crusher prices can be as low as $25,000 for basic models. Advanced machines can cost over $1 million. Think about how much you need to crush and what features you want. This helps you choose a crusher that fits your budget and needs.

Factors Affecting Cone Crusher Price

When you check cone crusher prices, you will see many things can change the cost. It is important to know these things before you buy a stone crusher machine. Each part of the machine, the technology inside, and where you buy it can change the price and your roi.

Capacity and Output

The size and power of cone crushers are very important. If you want a stone crusher machine that crushes more rocks each hour, you will pay more. Bigger machines have stronger and heavier parts. These parts cost more to make and send. When you pick a high-capacity crusher, you spend more at first, but you get more output.

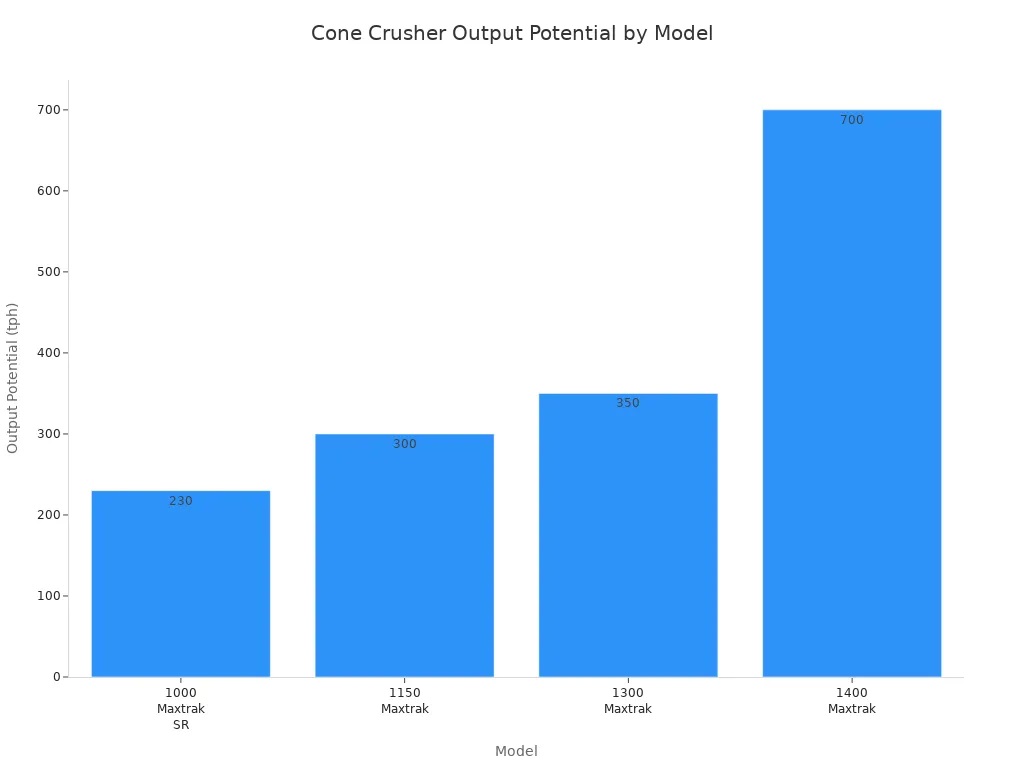

Here is a table that shows how output changes with different models:

|

Model |

Output Potential |

Weight (Tier 3) |

CSS Range |

|---|---|---|---|

|

1000 Maxtrak SR |

230 tph |

87,391 lbs |

0.7" - 1.6" |

|

1150 Maxtrak |

300 tph |

94,578 lbs |

0.7" - 1.8" |

|

1300 Maxtrak |

350 tph |

105,865 lbs |

1" - 1.8" |

|

1400 Maxtrak |

700 tph |

132,851 lbs |

1/4" - 3" |

If you choose a stone crusher machine with higher output, you pay more at first, but you might get better roi because you can crush more rocks.

Tip: Always pick a cone crusher with the right capacity for your project. If the machine is too big, you waste money. If it is too small, your work slows down.

Type and Model

Different types and models of cone crushers have different prices. Some machines are best for small jobs, while others are made for big mining projects. You need to pick the right model for your job to get the best roi.

|

Model Type |

Recommended Application |

|---|---|

|

PYB Spring Cone Crusher |

Small to medium-sized aggregate lines |

|

S Series Spring Cone Crusher |

Secondary crushing |

|

LMC Compound Cone Crusher |

Mid to high-end crushing projects |

|

DS/DH Single-Cylinder Cone Crusher |

High capacity, stable performance, hard ores |

|

HPY Multi-Cylinder Cone Crusher |

Smart mining, large-scale projects |

-

The PYB Spring Cone Crusher has a simple design and low price. It works well for small stone crusher machine jobs.

-

The S Series has more chambers and higher output, so it costs more.

-

The LMC Compound Cone Crusher is for high-performance jobs and costs more because it has advanced features.

-

The DS/DH Single-Cylinder models are reliable and have low production costs, good for buyers who want value.

-

The HPY Multi-Cylinder Cone Crusher uses smart technology and is for big mining jobs, so it has a higher price.

Raw Material Costs

The price of steel and other raw materials changes a lot. These changes affect the cone crusher price. In 2020, steel cost less than $500 per ton. By 2021, the price went up to $1,955 per ton. In 2022, steel dropped to less than $700 per ton. Big changes in steel prices can make stone crusher machine prices go up or down fast.

-

Steel prices can go up or down because of world events, like the COVID-19 pandemic.

-

When steel costs more, manufacturers raise the price of cone crushers.

-

If steel prices drop, you may see lower prices for new machines.

Note: You should watch raw material prices before you buy. Waiting for lower steel prices can help you save money.

Technology and Features

New technology makes cone crushers work better, but it also makes them cost more. Machines with automation, smart controls, and safety features cost more. These features help you save money over time by lowering energy use and maintenance costs.

|

Technological Advancement |

Impact on Pricing |

|---|---|

|

Automation |

Enhances operational efficiency and reduces downtime. |

|

IoT Connectivity |

Improves data collection and machine performance. |

|

Predictive Maintenance |

Minimizes unexpected failures and maintenance costs. |

|

Regulatory Compliance |

Increases production costs due to stringent standards. |

|

Global Trade Dynamics |

Affects raw material costs and availability. |

-

Automation helps you use less energy and makes your stone crusher machine safer.

-

Smart features let you change settings quickly and keep the machine running longer.

-

Predictive maintenance lowers repair costs and keeps your machine working.

-

One mining company saw a 20% increase in productivity and a 30% drop in maintenance costs after using a smart cone crusher.

Tip: Buying advanced technology can help your roi by saving money on repairs and energy.

-

Smart crushers also make less dust and noise, which can lower compliance costs.

-

Better crushing processes use less energy and help you meet sustainability goals.

Market Demand and Region

Where you buy your cone crushers changes the price. Some places have higher demand, which can make prices go up. In North America, there is high investment in new technology and strong infrastructure. Europe has strict environmental rules and supports sustainable machines. Asia-Pacific has cheaper manufacturing and is growing fast.

|

Region |

Key Factors Affecting Demand and Prices |

|---|---|

|

North America |

Established infrastructure, high investment in innovation, focus on next-gen technologies, favorable policies. |

|

Europe |

Stringent environmental standards, strong innovation ecosystems, government support for sustainable technologies. |

|

Asia-Pacific |

Rapid urbanization, industrialization, cost-effective manufacturing, increasing foreign investments. |

If you buy a stone crusher machine in a place with high demand, you may pay more. In places with lower labor costs, you might find better deals.

Import Duties and Transportation

Import duties and shipping costs can change the final cone crusher price. If you buy from another country, you may pay extra fees. These costs can mess up your budget and slow down your project.

-

Import duties can make the stone crusher machine much more expensive.

-

High shipping fees add to the total cost.

-

Picking machines that are in stock can help you avoid surprise fees and delays.

Tip: Always ask about import duties and shipping costs before you buy. This helps you plan your budget and get the best roi.

Types of Cone Crushers

When you search for a stone crusher machine, you will see many types of cone crushers. Each type is best for certain jobs and has its own price range. It is important to know the main types before you pick one.

Single-Cylinder Hydraulic

Single-cylinder hydraulic cone crushers use one hydraulic cylinder to adjust and protect the machine. You can use this stone crusher machine for mining, building, and making cement. It works well for crushing hard rocks like granite, basalt, and limestone. You will also find it in sand and gravel production.

-

You can use this type for:

-

Mining (iron ore, copper ore, gold ore)

-

Construction aggregates

-

Cement making

-

Sand and gravel

-

Recycling

-

The price for a single-cylinder hydraulic stone crusher machine usually starts at $80,000 and can go up to $1,500,000. The cost changes if you want a bigger size, more power, or new features. You may pay more if you want advanced technology or higher output.

Note: The need for single-cylinder hydraulic cone crushers in these jobs can make prices go up or down. Market trends and new technology also change the price.

Multi-Cylinder Hydraulic

Multi-cylinder hydraulic cone crushers use several cylinders for better control and more crushing power. You can use this stone crusher machine for big mining projects and places where you need to crush a lot of rocks fast. This type gives you more output and better shape for the final product.

-

Best for:

-

Large mining jobs

-

High-volume stone crushing

-

Projects needing fine and even crushed rocks

-

The price for a multi-cylinder hydraulic stone crusher machine ranges from $150,000 to over $1,050,000. You pay more for bigger machines and extra features like automation.

Other Variants

You will also find other types of cone crushers in the market. These include:

-

Standard cone crushers

-

Short head cone crushers

-

Compound cone crushers

-

Gyratory cone crushers

-

Diesel-powered cone crushers

-

Electric-powered cone crushers

Each type of stone crusher machine has special design features. For example, some have a large eccentric throw and a short chamber, like the Symons and Telsmith models. Others use a spider bearing, such as the Hydrocone. You should pick the right type based on your job and the kind of rocks you need to crush.

|

Type |

Typical Price Range |

Best Application |

|---|---|---|

|

Standard Cone Crusher |

$50,000 - $150,000 |

General stone crushing |

|

Short Head Cone Crusher |

$60,000 - $180,000 |

Fine crushing, sand making |

|

Compound Cone Crusher |

$70,000 - $200,000 |

Versatile, mixed materials |

|

Gyratory Cone Crusher |

$100,000 - $500,000 |

Large-scale mining |

|

Diesel/Electric Powered |

$25,000 - $100,000 |

Remote sites, flexible power needs |

Tip: Always match the stone crusher machine to your project. The right choice helps you save money and get better results.

You can see that there are many types of cone crushers. Your choice depends on your needs, budget, and the kind of work you do.

Buy Cone Crushers: Evaluation Tips

Assessing Needs

Think about your project before you buy cone crushers. First, decide what rocks you want to crush. Next, figure out how much you need to crush each day. The table below shows what you should check:

|

Criteria |

Description |

|---|---|

|

Material Characteristics |

Think about how hard, rough, or wet your rocks are. |

|

Production Requirements |

Choose the size, amount, and how much you want to make. |

|

Operational Environment |

See if your site is hot, dusty, or wet. These things can change how your crusher works. |

|

Maintenance and Support |

Pick a company that gives good warranty and spare parts. This helps your crusher last longer. |

|

Cost Considerations |

Look at all costs, not just the first price. Include costs for running and fixing the machine. |

Tip: If you pick a crusher that fits your job, you will save money and get better results.

Comparing Specifications

When you look at cone crushers, check more than just the price. Here are some easy steps:

-

Look at how much each crusher can crush and how strong it is.

-

Make sure the crusher fits your needs and works well.

-

Think about costs for repairs and care, not just the first price.

-

Pick a machine that gives you good value and has helpful features.

Checking Manufacturer Support

Good help from the company makes your crusher work better. The table below shows what top brands give you:

|

Manufacturer |

Support Options |

Impact on Total Cost of Ownership |

|---|---|---|

|

Eagle Crusher |

Offers payment plans and help any time |

Lowers repair costs and keeps your crusher working |

|

Metso:Outotec |

Gives service plans for your business |

Helps your crusher run better |

|

Powerscreen |

Has many crusher choices and support |

Makes your work faster and costs less |

|

Sandvik |

Has automatic controls and safety features |

Makes changes easy and lowers repair needs |

Note: Good help and a strong warranty make your crusher last longer and stop expensive problems.

Requesting Quotes

To find the best price, ask for quotes from different sellers. Follow these steps:

-

Use a tool to get free quotes from many sellers.

-

Tell each seller about your project and what you need.

-

Look at the quotes and pick the best one for your job.

-

Compare all offers before you choose.

Tip: Always check what comes with the quote, like delivery, setup, and help after you buy.

Operational Costs and ROI

Knowing the costs of running cone crushers helps you make good choices. You should think about more than just the first price. Look at how setup, care, energy, and work affect your total cost and how much money you make back.

Installation and Setup

Setup costs change based on your project and what you pick. Small stone crusher plants cost between $230,000 and $700,000 to set up. If you use a simple system with a jaw crusher, screen, and belts, it may cost $100,000 to $250,000. If you want extra crushers and smart controls, costs can go over $500,000. Stationary plants cost more because they need buildings. Mobile crusher plants cost less at first, like buying trucks.

Tip: Always look at setup costs for both stationary and mobile crushers. This helps you plan your spending and get ready for upgrades later.

Maintenance and Parts

Taking care of your crusher is very important for costs. If you skip regular care, you will pay more and lose time. Buying good cone crushers and parts helps you fix less and keep working.

-

Long-term care costs can change your total spending.

-

Changing parts often and stopping work raises costs.

-

Paying workers for care adds up fast.

-

Strong crushers need less care and save you money.

-

Doing regular checks and smart care makes your crusher work better and cost less.

-

Good parts help you fix less and save money over time.

Energy Use

How much power your crusher uses changes your costs every day. Most cone crushers use about 241.11 kW·h when not working and up to 385.10 kW·h when busy. Most machines use between 381.56 kW·h and 388.63 kW·h. If you pick crushers that use less power, you pay less for electricity and make more money back.

Productivity and Payback

You want your crusher to work well so you get your money back faster. You can figure out how long it takes by looking at cost-per-ton, including fuel, care, and training. Running your crusher at 60-70% of its full power helps you earn more and get your money back sooner. Sorting rocks before crushing and using good systems also help you work faster. If you know what people want in your area and sell smart, you can get your money back in 12-24 months.

|

Factor |

How It Impacts ROI and Payback Period |

|---|---|

|

Cost-per-ton analysis |

Shows real costs and helps you plan your money |

|

Equipment utilization |

Using your crusher more means faster payback |

|

Productivity strategies |

Better work means you earn money quicker |

|

Market positioning |

Selling smart helps you get paid back sooner |

Note: Always treat your crushing work like its own business. This helps you watch your costs and see how much money you make more clearly.

You have seen that cone crusher price depends on many things like capacity, type, features, and region. Always look at both the first price and the ongoing cost to get the best roi. To choose the right crusher for your needs, follow these steps:

-

Check your crushing needs and pick the right capacity.

-

Make sure the feed opening fits your largest rocks.

-

Choose the right crushing stage and setup.

-

Compare prices and support from different suppliers.

Careful planning helps you find the best price and long-term value.

FAQ

What is the main difference between single-cylinder and multi-cylinder cone crushers?

Single-cylinder cone crushers have just one hydraulic cylinder for changes. Multi-cylinder crushers have more than one cylinder. Multi-cylinder types are stronger and give better control. They can crush more rocks and make better-shaped pieces.

How often should you perform maintenance on a cone crusher?

You should look at your cone crusher every day. Clean it and check if any parts are worn out. Change old parts when you need to. Follow the maker’s plan for oil changes and big checkups. Taking care of your crusher helps it last longer.

Can you use a cone crusher for all types of rocks?

Cone crushers work with many rocks, like granite, basalt, and limestone. Harder rocks need tougher machines to crush them. Always read the crusher’s details before you use it. Some crushers are better for certain kinds of rocks.

How do you choose the right size cone crusher?

First, find out how big your biggest rocks are. Then, see how much you want to crush each hour. Pick a crusher that fits your rock size and how much you need to crush. If you are not sure, ask the seller for help.

What factors affect the lifespan of a cone crusher?

Doing regular care, using good parts, and running the crusher right help it last longer. Too much weight, not enough oil, or wrong settings can make it break sooner. Always do what the maker says for the best results.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported