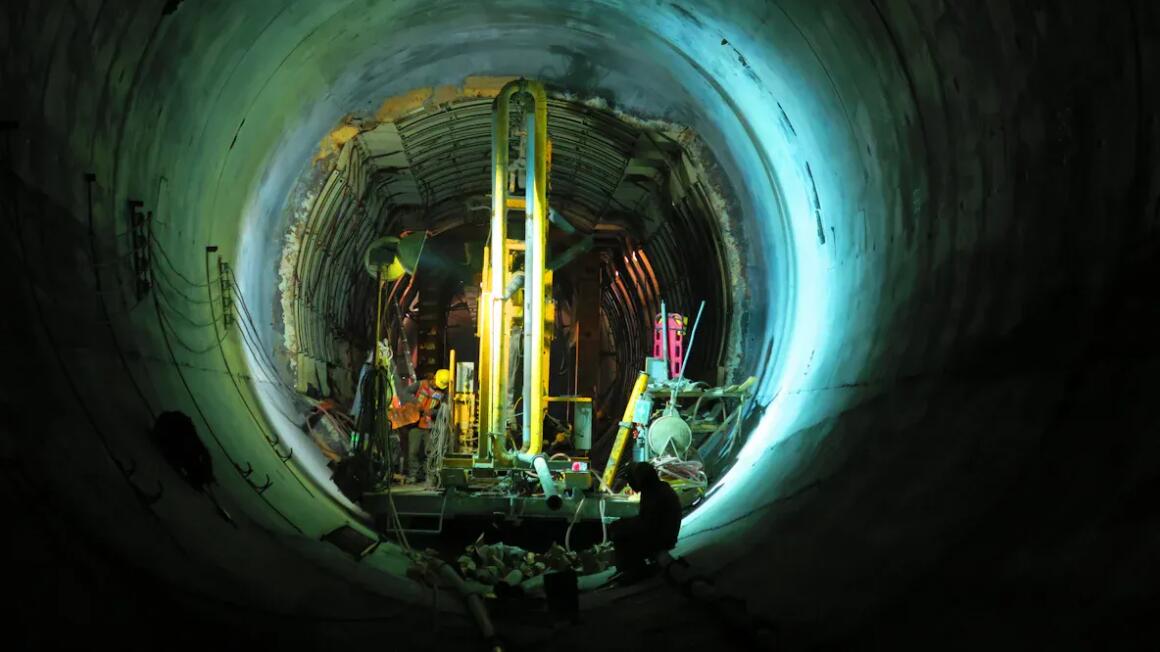

When working underground in challenging environments, you utilize specialized tunnel boring equipment, including the Tunnel Boring Machine. The Earth Pressure Balance TBM is essential for maintaining ground safety, particularly in areas where the soil may be soft or saturated. Common types of soil encountered include:

Nhiglobalequip provides you with Tunnel Boring Machine solutions, enabling you to excavate safely and efficiently, even in difficult conditions.

You might ask what makes an Earth Pressure Balance Tunnel Boring Machine different. This machine is made for digging in soft ground. It uses the soil it digs up to hold up the tunnel face. This keeps the ground steady and stops the ground from sinking. It also helps keep water out of the tunnel.

Here are some main ways EPB TBMs are not like other machines:

Using an Earth Pressure Balance Tunnel Boring Machine lets you dig safely in tricky places. These places might have moving ground or lots of water. That is why people use them for city subways and tunnels under rivers.

To see how an EPB TBM works, you should know its main parts. Each part has a job that helps you dig safely.

| Component | Function |

|---|---|

| Shield | Keeps the machine safe and holds up the tunnel walls. |

| Screw Conveyor | Moves soil out of the pressurized area and controls how much soil leaves, so pressure stays steady. |

| Soil Conditioning System | Makes soil easier to work with, lowers cutting force, and helps soil move smoothly. |

The shield is like a hard shell around the Tunnel Boring Machine. It keeps the tunnel in shape and protects workers and the machine. The screw conveyor slowly takes soil away from the front. You can change its speed to control how much soil leaves and keep pressure right. The soil conditioning system adds things to the soil to make it less sticky and easier to move.

Tip: If you know what each part does, you can use the Tunnel Boring Machine more safely and easily.

You use an Earth Pressure Balance Tunnel Boring Machine to dig tunnels. This machine lets you make tunnels without digging up the ground above. This is called trenchless tunneling. It works best in soft or wet ground. The machine keeps the tunnel face steady by matching the pressure inside with the pressure outside.

Keeping this balance is very important. If you take out soil too fast, the ground can fall in. If you go too slow, the ground can push into the tunnel. The Tunnel Boring Machine helps you avoid these problems.

Here is a table that shows how EPB TBMs and slurry TBMs are different:

| Mechanism | EPB TBMs | Slurry TBMs |

|---|---|---|

| Pressure Control | Changes chamber pressure to match earth and water pressure. | Uses bentonite slurry to keep pressure at the tunnel face. |

| Soil Support Medium | Uses dug-up soil to hold up the tunnel face. | Mixes soil with slurry to support and move it. |

| Soil Conditioning | Adds things to make the soil easier to work with. | Uses foam and other agents to help soil flow. |

Note: You must always keep the pressure balanced. This stops the ground from falling in or water from leaking.

You need to keep the front of the tunnel strong and safe. EPB Tunnel Boring Machines use soil conditioning to help with this. Soil conditioning means you add things like foam or polymers to the soil. These things change the soil so it is easier to move and less sticky.

You pick the right thing to add based on the kind of soil. Here is a table that shows which things work best for different soils:

| Soil Type | Conditioning Agent Type | Foam Injection Ratio (FIR) | Polymer Injection Ratio (PIR) |

|---|---|---|---|

| Thanet Sand | Foam | More foam, less liquid | N/A |

| London Clay | Polymer | Less foam, more liquid | Higher PIR, lower FIR |

Tip: Try out different things before you start digging. This helps you find the best mix for your soil and keeps the tunnel face safe.

The screw conveyor is an important part of the Tunnel Boring Machine. It moves the treated soil out of the pressurized area. You can change how fast the screw conveyor goes to control how much soil leaves the tunnel face.

If you are working in ground with big rocks or sticky clay, you can slow down or speed up the conveyor or use stronger soil conditioners. This makes EPB Tunnel Boring Machines good for many kinds of soil.

Alert: Always watch the screw conveyor speed. If the soil flow changes, change the speed or the soil conditioners to keep the tunnel safe.

You can keep your Tunnel Boring Machine working well by following some simple steps. These steps help stop breakdowns and make your machine last longer:

Tip: Predictive maintenance helps you watch the cutter’s condition. You can plan to replace it before it breaks. This saves time and money.

You may have some problems when using an EPB TBM. Keeping soil pressure balanced and knowing what is underground are big challenges. Here are some common problems and ways to fix them:

| Leading Causes of Delays | Effective Solutions |

|---|---|

| Inaccurate geological predictions | Use machine learning to make better guesses |

| Challenges in maintaining soil pressure balance | Use new ways to keep soil pressure steady |

Note: Knowing how long machine parts will last helps you plan fixes. This stops delays that cost a lot of money.

You must follow safety rules to keep your team and equipment safe. Wear helmets, face shields, bright vests, and masks to protect from falling things and dust. Check your equipment before you start work. This lowers the chance of something breaking. Studies show regular checks can cut hydraulic problems by 35%.

New Tunnel Boring Machine designs, like better ground conditioning and dual mode TBMs, make tunneling safer and faster. These new ideas help you work well even when the ground changes.

Callout: Good EPB TBM practices help you control earth pressure. They also make tunneling projects more likely to succeed, especially in soft ground.

You get many good things when you use an Earth Pressure Balance Tunnel Boring Machine in soft ground. This machine helps keep the ground safe and steady. It works well in clay, sand, or silt. You can use it in cities with lots of buildings and roads. The machine keeps pressure even, so the ground does not sink or shift. This means less harm to streets and homes above.

Here is a table that shows how EPB TBMs and old tunneling ways are different:

| Advantage | EPB TBMs | Traditional Methods |

|---|---|---|

| Handling of voids | Better because it uses strong material | Not as good |

| Adaptability | Works in many types of ground | Does not work as well |

| Initial Cost | Usually costs less for builders | Costs more most times |

EPB TBMs work better in soft ground. They change to fit the soil and cost less to start. You also stop the ground above from sinking and keep the city working. The design lets you dig near important buildings without trouble.

EPB TBMs also do well in mixed ground. You can use them in places with soft soil and hard rock. The machine keeps pressure right and protects the tunnel face. This makes it good for many jobs.

You can see EPB TBMs used in many big projects around the world. These machines help build tunnels in hard places. Here are some examples:

You learn important things from these projects. For example, the DigIndy project in Indianapolis used a rebuilt Tunnel Boring Machine. Reusing machines helps the environment. The project dug over 45 kilometers of tunnels and cleaned up the river. Fish came back, showing good results.

When you pick an EPB TBM, you look at soil, rock, water, and tunnel size. You test the ground and check water pressure. This helps you choose the best machine for your work. EPB TBMs let you dig safely and quickly in many places.

Tip: EPB TBMs help stop the ground above from sinking and keep cities safe while digging tunnels. You can use them for subway lines, water tunnels, and sewer jobs.

You can trust EPB TBMs for safe and quick tunnel work. These machines use strong ground support and watch the tunnel in real time. This helps your project stay on schedule.

| Benefit | Why It Matters |

|---|---|

| Efficiency | Makes building faster |

| Safety | Keeps workers and nature safe |

| Precision | Stops too much shaking of the ground |

You should always use good methods and know your soil. As machines get better, tunneling will be even safer and smarter.