Recent changes in tunnel boring machines have changed how tunnels are built for mining and civil engineering. Companies use AI-driven systems to make tunneling more exact and to stop work less often. The Asia-Pacific area is growing fastest in these projects. China and India help this growth as cities get bigger around the world.

|

Date |

Event Description |

|---|---|

|

Dec 2024 |

Caterpillar Inc. started using an AI-driven TBM system to make tunneling more exact and finish faster. |

|

Oct 2023 |

Siemens made an AI-powered system for predictive maintenance, which cuts downtime by 20%. |

|

Jan 2025 |

ITA said high TBM costs stop smaller contractors in new markets. |

|

N/A |

Asia-Pacific grows fastest for TBMs because of more cities and new infrastructure. |

|

N/A |

China and India help TBM market grow with many city building projects. |

Tunnel Boring Machines: Advantages

Efficiency and Speed

Tunnel boring machines have changed how engineers build tunnels. These machines dig up to 700 meters each week. Projects finish faster and do not disturb cities as much.

-

TBMs help teams finish tunnels quickly.

-

The faster work saves money and stops delays.

-

Cities have less noise and fewer traffic problems.

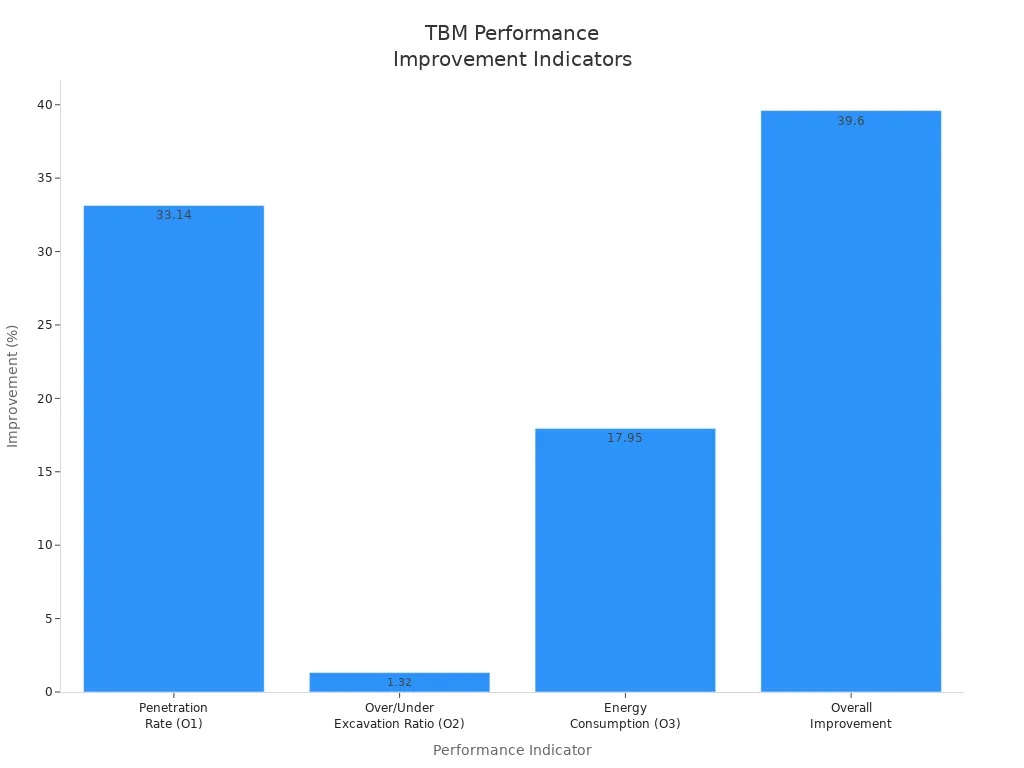

A study found TBMs make projects better:

|

Performance Indicator |

Improvement (%) |

Reliability Improvement (%) |

|---|---|---|

|

Penetration Rate (O1) |

33.14 |

91.16 |

|

Over/Under Excavation Ratio (O2) |

1.32 |

76.92 |

|

Energy Consumption (O3) |

17.95 |

97.35 |

|

Overall Improvement |

39.60 |

N/A |

Safety Improvements

TBMs make tunneling safer for workers. The machines use barriers and automatic systems to keep people safe.

-

TBM work uses careful steps, so accidents happen less.

-

Workers have fewer health and safety problems.

-

Fewer people die than with open-face methods.

|

Safety Feature |

Description |

|---|---|

|

Noise and Vibration Reduction System (NVRS) |

Cuts down noise and shaking, making work better and helping people nearby accept it. |

|

Automated Systems |

Need more sensors and controls, built to last in tough tunnel places. |

|

Physical Barriers |

Put up to block entry to areas with machines, making manual work safer. |

Environmental Impact

Tunnel boring machines help protect nature. TBMs disturb less soil and control ground settling better than old ways.

|

Metric |

TBM Performance |

Traditional Methods |

|---|---|---|

|

Maximum Recorded Subsidence |

13.1 mm |

30 mm (allowable limit) |

|

Soil Disturbance |

Minimal |

Higher |

|

Ground Settlement Control |

Superior |

Less effective |

TBMs can be used again for other jobs, which lowers pollution. Smoother tunnel walls need less support and make less waste.

Tunnel Boring Machine Technology

Historical Evolution

The tunnel boring machine story started almost 200 years ago. Engineers wanted to dig tunnels safely and quickly. There are some important moments in tunnel boring machine history:

-

In 1825, Marc Brunel made the first tunnel shield for the Thames River. This was the beginning of soft ground tunnel boring machines.

-

In the 1850s, workers used drill and blast to dig rock tunnels. This way was popular until machines were invented.

-

In 1954, James Robbins built the first rock tunneling machine that worked well. He added the disc cutter, which made digging rocks easier.

These moments show how tunnel boring machines changed over time. Early machines cared about safety and simple digging. Later machines got faster and worked better. Engineers today keep improving these old ideas.

Recent Innovations

Modern tunnel boring machines have many new features. Engineers use artificial intelligence to make tunneling easier and more automatic. AI-based subsystems help run TBMs by modeling, watching, and controlling them. These systems make machines work better and help with new research in tbm automation.

Advanced monitoring systems are very important now. They give workers real-time data to help them decide what to do. Load cells and torque transducers help automate many jobs. This makes work faster and smoother. Safety systems use load cells to stop overloading and find dangers. Sensor data helps teams do better and improve tunneling ways. Monitoring also checks drilling and keeps equipment safe. These things help mining and civil engineering projects succeed.

New designs, like the rectangular tunnel boring machine with planetary transmission, cut better and mix soil well. This machine keeps the ground steady during box jacking under roads. It can dig through mixed soil and handle tough spots. These features help build things in cities.

Tip: Modern tunnel boring machines use tbm automation and advanced monitoring to make tunneling safer, faster, and more reliable.

Tunnel boring machine technology keeps changing how engineers build tunnels. These machines help teams finish faster and lower risks. New advances in tbm automation and monitoring make mining and civil engineering safer and better.

Mining Applications

Hard Rock Tunneling

Mining companies use tunnel boring machines to reach deep minerals. TBMs work well in hard rock because they handle tough surfaces. These machines help engineers build long tunnels for mining.

-

TBMs work fast in long tunnels, so they are good for mining jobs that need long underground paths.

-

Operators pick TBMs by looking at machine details and what the job needs. This helps them get the best results in hard rock.

-

Engineers use Discrete Event Simulation (DES) to see how TBMs work with different rocks. This helps teams plan and solve problems.

TBMs dig tunnels automatically, so workers do less manual work. This makes the job safer and keeps things steady. Mining teams finish faster and face fewer dangers.

Resource Extraction

Getting resources from mines needs careful and safe digging. TBMs are a new way compared to old drilling and blasting. These machines make smooth tunnels, which helps move minerals and tools.

The table below shows how TBMs and drilling and blasting compare in studies:

|

Study Title |

Focus |

Findings |

|---|---|---|

|

Mechanical Excavation and Drilling and Blasting – A Comparison Using Discrete Event Simulation |

How well drilling works |

The study looks at how different tools change drilling speed. It shows TBMs need fewer changes than drilling and blasting. |

|

Assessing prediction models of advance rate in tunnel boring machines—a case study in Iran |

Comparing ways to predict TBM speed |

The research finds math models, like the Barton model, can guess how TBMs work in some rocks. |

|

Statistical analysis of tunnel blast schemes |

Managing tunnel projects |

This study uses numbers to show how drilling and blasting work. It connects drilling ways with how hard tunneling is and how much it costs. |

TBMs use fewer explosives, so there are fewer accidents and less damage. They also make less shaking and noise, which is better for sensitive places. Mining teams like smooth tunnels because it is easier to move things.

Note: TBMs help mining companies reach important minerals with less harm to nature and people nearby.

Mining teams now pick TBMs for many jobs because these machines give better control, more safety, and higher output. Moving from drilling and blasting to TBMs is a big step in mining.

Infrastructure Applications

Urban Tunnels

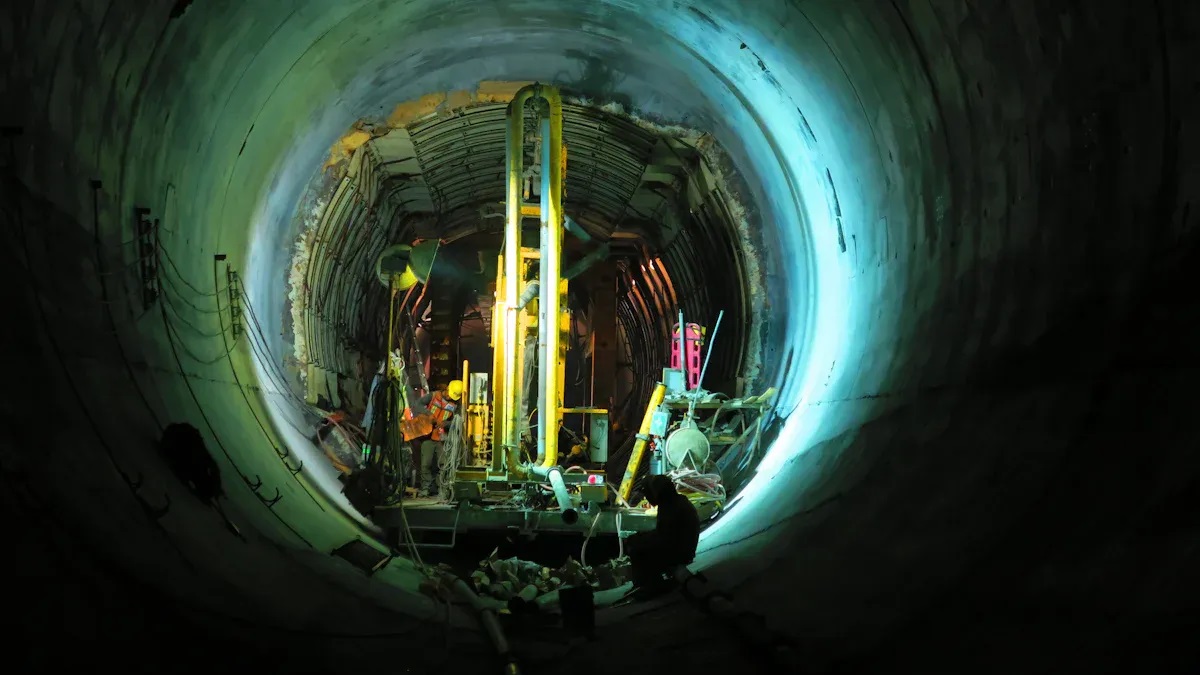

TBMs are important for building tunnels in cities. These machines help engineers dig under busy streets and homes. TBMs make less noise and shaking, so people above do not notice much. They also stop the ground from sinking, which keeps buildings and roads safe.

-

TBMs use earth pressure balance and slurry shield designs to lower risks from sinking and empty spaces.

-

Teams need to check things like pipes and other tunnels before they start.

-

These machines let cities build more underground without hurting daily life.

TBMs make city tunnel jobs safer and faster. They help cities grow and keep people and nature safe.

Transportation Projects

TBMs are used in many transport projects. Metro trains, roads, and stations all use these machines. TBMs dig tunnels with smooth walls. This helps trains and cars move safely and quickly.

-

TBMs help finish tunnel work faster.

-

They make work safer by needing less manual labor and keeping workers away from danger.

-

TBMs cause less shaking, so nearby buildings and nature stay safe.

One example is the Metro Tunnel Project in Melbourne. Workers moved two TBMs that weighed 660 tons each. It took three days and nights to do this. They used hydraulic jacks and skidding systems to keep things safe and easy. This project is the biggest public transport job in Victoria’s history. It shows how TBMs help big transport projects and make city life better.

Challenges and Opportunities

Geological Constraints

TBMs have problems when digging in different ground. Mining jobs often go from hard rock to soft, wet dirt. Multi-Mode TBMs let teams change how they dig for each ground. These machines help keep workers safe and let them work in many places. They can handle hard jobs, like moving from strong rock to loose, wet ground.

-

Multi-Mode TBMs change how they dig for each ground.

-

They help keep workers safe and finish jobs on time.

-

These machines work well in tricky mining spots.

|

Aspect |

Description |

|---|---|

|

Adverse Geological Conditions |

TBMs have trouble when the ground changes fast. |

|

Mitigation Measures |

Teams use special machines and plans to fix these problems. |

|

Research Needs |

More studies can help teams find better ways to solve ground problems. |

Cost Factors

Using TBMs in big mining jobs costs a lot for many reasons. Project leaders must think about where the tunnel is and how big it will be. These things are hard to control while working. Teams can plan better before they start digging. They might make the tunnel shorter, use fewer tubes, or have fewer crossways. Good planning helps save money and keeps the job on track.

Future Trends

New ideas make tunneling safer and smarter. Variable Density TBMs can change the thickness of the slurry for each ground. This helps control the ground and stops sinkholes almost all the time. Autonomous TBMs use AI to guide the machine. These smart machines make work safer, save money, and help teams dig more exactly.

-

Variable Density TBMs change for different soils.

-

Autonomous TBMs use AI for better safety and control.

-

Mining teams use these new machines for safer and cleaner jobs.

Smart tunneling ideas will help teams build better tunnels in the future.

Tunnel boring machine improvements make mining and building safer. They also help teams work faster and better. But teams still have problems with high costs and tough ground. New technology will bring even smarter ways to dig tunnels. People can see how these machines help make the world better for all.

Company Profile

Company Profile Social Responsibility

Social Responsibility Get A Quote

Get A Quote

IPv6 network supported

IPv6 network supported